TE . AN. -CHANGES

Page 58

Page 59

Page 60

Page 61

If you've noticed an error in this article please click here to report it so we can fix it.

[E, PICTURE

ITHOUT implying that the latest Leyland Atlantean double-decker design is the complete answer to every . bus operator's' prayers, -I . would suggest that it is perhaps the nearest approach to theldeal configuration so far offered on the British market. Its layout offers many benefits over more conventional Vehieles—all at no chassisprice disadvantage—and it should do_much to arrest the decline in income at present being felt by the majority of

undertakings. •

The appeal of the Atlantean is widespread: passengers will appreciate the easy loading, low engine noise and situ:loth ride; drivers will find it less tiring to handle in all respects; conductors will_ have reduced responsibilities; maintenance men will welcome the high degree of engineaccessibility; and generalManagers should-find that passenger-mile costs are lower.

These are my conclusions after making the first road test of this. new design, the test vehicle being the Alexanderbodied-78-seat high-bridge bus exhibited the previous week at the Commercial Motor Show. This bus was built to the order of Glasgow Corporation Transport, with whom it is now in service as No. LA!, and the full-load testing was made with the equivalent of 82 passengers, driver and conductor.

On standard tyres, the . Atlantean chassis . is rated by the makers at a gross vehicle weight of 13,tOns 15 cwt., but

the Glasgow bus was tested at about half-a ton more than this. SOrne of thiS-exCesS was probably, in the construction of the body, this. being the first-Atlanteah body to be produced by •Alexander's. It should be possible to cut the body weight to lessthan the 3 tons 4 cwt: of the test vehicle by judicious paring, and so bring the gross running weight, even with standing passengers, to under. 14 tons. Low-bridge

bodies onto this 'chassis will be at least 5 cwt. lighter, and because of the reduced• passenger capacity, Should operate at up to half a ton less than the weight of the test bus.

On test, the Atlantean was shown to•have acceleration at least as good as that of a normal .27-ft. double-decker running some 3 tons lighter, whilst the braking power was more than sufficient for a high-capacity passenger vehicle. The vehicle had covered less than 1,100 miles before the test, despite which quite reasonable fuel-consumption figures Were returned under a variety of operating conditions. These gave good economy in terms of passenger-mpg.

The Atlantean chassis was' fully described and illustrated in the September 5 issue of The Commercial Motor. It has many interesting features, including the use of a ,loadcarrying chassis frame which allows .a wide variety of body types to be mounted on it without the need for highly stressing the body components. It will be recalled that the original Atlantean design was fully integral, thus it was restricted in the type of bodywork suitable.

The rear engine layout has several advantages, not the least of these being that a wide, low-step entrance platform can be incorporated ahead of the front wheels and in full view of the driver. This platform is 4 ft. 8 in. wide. The .rear engine also means that there is less noise in the body—

the engine compartment being separate from the lower saloon—and accessibility and removal are much easier than is possible with forward-engined buses.

The low frame height has been achieved without the use of independent suspension at either axle, thereby simplifying the design, and this low height makes it possible to mount bodies with an 'overall height of 13 ft. 4 in. unladen with a side gangway only at the last three rows of seats on the upper deck. The test bus had an overall unladen height of 14 ft. 4+ in. The chassis would be eminently suitable for high-speed double-deck coaches also, whilst it should be relatively easy to produce a long-wheelbase version for 35-ft. single-deck bodies for export.

The dry weight of the test bus was 8 tons 16 ewt. according to the weight figure on the side of the vehicle, and with full tanks and various items of test equipment aboard the kerb weight was 9 tons cwt. Iron weights totalling 5 tons 1cwt. had been placed in the body, so that there was the equivalent of approximately 44 passengers in the upper saloon, this being the seating capacity upstairs.

Braking tests were attempted on the Southport road at Tarleton, but only one full-pressure stop was made, this being from 20 m.p.h. and resulting in the loose weights shifting in a dangerous manner. The stopping distance of 25. ft. was sufficient to prove that the brakes are highly efficient however, and had it been possible to make a stop • from 30 m.p.h. a figure of no more than about 56 ft. should have been obtained.

The one stop that was made revealed the retardation to be quite smooth, despite the fact that all the test weights moved, and there were no signs of grabbing. Because of the sudden transference of load the rear wheels locked for a short distance, and heavy marks on the road indicated that the front wheels were just on the point of locking also.

When driving normally I found the brakes to be entirely proportional to pedal effort and completely safe under all conditions. For steady retardation only light pedal pressure is required, which makes driving more pleasant in heavy traffic. A stop was made on the hand brake from 20 m.p.h. and this produced a Tapley meter reading of 21 per cent., which is good for a fully laden 78-seater.

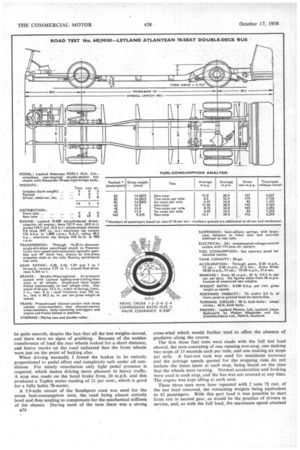

A 5.9-mile circuit of the Southport road was used for the seven fuel-consumption tests, the road being almost entirely level and thus tending to compensate for the mechanical stiffness of the chassis. During most of the tests there was a strong B26

cross-wind which would further tend to offset the absence of gradients along the course.

The first three fuel tests were made with the full test load aboard, the tests consisting of one running non-stop, one making two stops of 15 seconds each per mile, and one making six stops per mile. A fuel-test tank was used for maximum accuracy and the average speeds quoted for the stopping runs do not include the times spent at each stop, being based on the time that the wheels were turning. Normal acceleration and braking were used at each stop, and the bus was not coasted at any time. The engine was kept idling at each stop.

These three tests were later repeated with 2 tons 7f cwt. of the test load removed, the remaining weights being equivalent to 42 passengers. With this part load it was possible to start from rest in second gear, as would be the practice of drivers in service, and, as with the full load, the maximum speed attained between stops when making six per mile rarely exceeded 25 m.p.h.

The final fuel test was conducted with all the test weights removed, and this run was made non-stop. As the consumption analysis shows, the figures obtained were between 2 and 3 m.p.g. heavier than those to be expected from a 27-ft. bus carrying about 20 passengers fewer_ This gives a worthwhile advantage in terms of passengers per m.p.g.; furthermore, these extra passengers can be carried without additional wages for driver and conductor. This asset is invaluable for efficient peak-period operation.

The fully laden tests were made in an ambient 'temperature of 60° F., and at the end of the six-stops-per-mile test the engine oil and water temperatures were taken, these being 157° F. and 154° F. respectively. These temperatures are a little lower than might be desired for maximum efficiency and economy, but they do show that the Atlantean has ample cooling capacity for high-density operation in hot weather. At the end of this test there were no obvious indications Of brake fade. • For the gradient ability test I drove the bus through the centre of Preston and out to Kittlingborne Hill, where the Maximum gradient is 1 in 61. Facing up the slope, the bus was stopped and held quite easily on the hand brake. A bottom-gear restart was then made, a slight amount of initial roughness at the centrifugal clutch being noticed. Facing down the hill, the bus was again stopped and held satisfactorily on the hand brake. A restart in reverse was then made and this time the transmission was entirely Smooth in take-up, reverse gear being lower than first and therefore requiring less torque through the. clutch.

During the run through Preston I found the Atlantean almost child's play to handle. The forward visibility is outstanding, it being possible to see to within 5.ft. 6 in. of. the front of the bus at ground level, Wand the finger-4ip gear-change lever makes it simple to engage the most suitable gear for traffic 'conditions and So keep journey time down to a minimum.

Following the hill performance• tests, I took the bus on to the Lytham road for acceleration tests. For the standing-start times the Atlantean was started off in bottom gear and the average figures obtained are first rate for a vehicle running. at over 141 tons gross weight, particularly in view of the high wind resistance given by the large, flat frontal area of the vehicle. 'Smooth gear changing was noted, despite the continuous use of full throttle, and better times would hardly have resulted even had the fully automatic version of the Pneumo-Cyclic gearbox been fitted, this being optional.

Despite the fact that the centrifugal clutch does not engage fully in top gear until a road speed. of about 14 m.p.h. has been reached, good direct-drive times were obtained also, the acceleration between 10 and 15 tn.p,h. and 15 and 20 m.p.h. being almost constant, with a slight fall-off between 20 m.p.h. and 30 m.p.h. The maximum speeds in each gear were: first, 9 m.p.h.; second, 18 m.p.h.; third, 29 m.p.h.; and top, 45 m.p.h.

Impression of Floating • The Atlantean handled well at all times during the two days of testing and irrespective of the loading or road surface. The driver almost gets the impression of " floating " along because little engine noise penetrates that far forward. This absence of engine noise does much to relieve driving fatigue and it does not affect gear changing because no finesse is required to operate the semi-automatic gearbox. In any case, the speedometer gives sufficient indication as to gear-changing speeds. and the gearswitch box incorporates a sliding gate to make it impossible to change down from top to Second or first without engaging third.

The steering is well balanced, being comfortably firm at speeds up to 45 m.p.h. with a helpful degree of castor action to be of assistance when cornering. Bends can be taken at high speed without excessive roll being noticeable in either saloon, and there is a wide roll safety margin, the tilt test having been taken to 29° 55'.

When manceuvring at fairly low speed the steering is by no means heavy: indeed, many forward-engined 27-footers have much .heavier steering, It should not take drivers long to get used to the size of the front overhang, this being about the same as that of a front-entrance single-decker. The deep windscreens are of great assistance in judging the front sweep when turning in confined spaces. The two-spoke steering wheel is pleasant to use and there are 51 turns from lock to lock..

The suspension attains a high standard whether laden or 'empty. From the rear seats in the upper saloon it is possible to see a certain amount of fore-and-aft pitching, but this is accentuated by the length of the bus and is not felt as much as it is seen. In the lower saloon the ride is as good as can be possible with steel springs and air suspension could not give much better riding characteristics. Supplementary air springs are offered for the front axle for trial service, however, principally to ensure a constant-loading platform height.

This smooth ride is one of the advantages of this design that passengers will appreciate. Others are the low engine noise throughout the bus--in the upper saloon the engine is almost inaudible, and even at the rear of the lower saloon it is no worse than that of an underfloor-engined single-decker; the easy loading through the wide front entrance; the five-ahreast seats at the rear of each saloon; the absence of surge when accelerating; and the minimum transference of engine vibration, even when the power unit is idling. The absenceof a centre bearing avoids another possible source of vibration.

The 'driving compartment, which is reached through a halfdoor leading from the .entrance platform, is quite 'roomy. The seat is fully adjustable and the steering column is comparatively short, with the result that the steering wheel is' at waist height —a restful position. The longish gear-change switch can be operated without the need to remove the left hand from the steering wheel, thus further reducing the driving effort. All electrical switches are well placed for quick operation, and the dip switch is on the floor.

The Alexander body was found to be quite free from creaks and rattles during the test and the standard of finish is high. The front panel, which is a plastics moulding, is attractively styled and helps to offset the somewhat austere appearance of the bus caused by the flat front outline.

Limited Pram Stowage The luggage rack over the .off-side front wheel is handy for small cases and parcels, but mothers will miss the space 'for a folding pram which is found beneath the stairs of a rear-entrance bus.' With the Deans jack-knife doors closed an .annoying whistle occurred, caused by the gaps between the two. door

sections and between the doors and the floor. • Maintenance tests were confined to the engine and gearboxes, these being accessible through the plastics cowl at the rear of the bus. Other routine maintenance has been cut to a minimum by the provision as standard of a 24-point automatic lubricator, leaving only three points on the propeller shaft to grease Manually, and the use of Bendix-Westinghouse slack adjusters at the brakes. Pit jobs are pretty well confined to lubrication of the rear axle and periodic brake adjustment.

The engine cowl is secured in place by five spring fasteners.

actuated by a budget key, and it took me 35 seconds to raise and support this cowl. On the test bus the cowl was a prototype moulding with a flexible lower edge, but this is to be reinforced on production vehicles so that it does not foul the engine when it is raised, as occurred when I did it. Similarly, a telescopic support will be provided on production vehicles, whereas I had to use a separate prop to keep the cover up. A light is provided for first-aid repairs at night, the bulb being on a swinging arm.

This done, I checked the radiator water level in 71 seconds, the engine oil in 7 seconds, the gearbox oil in 24 seconds and the bevel-box oil in 34 seconds, the filler and level plug in this last-mentioned having tight threads, hence the longer time. The paper-element air filter is easy to reach, and I removed its element in 24 seconds and replaced it in 241 seconds.

There are two main fuel filters, grouped side by side, and removed the element in one of these in 31 seconds, replacement taking 50 seconds. Thus, both elements can be renewed in under 21 minutes. As a final task, I removed No. 1 fuel injector, this taking 2 minutes 54 seconds, I minute 9 seconds of this time being spent in removing the tappet cover to gain access to the injector. Replacement took 3 minutes 45 seconds, the cover replacement alone taking 1 minute 32 seconds of this time.

1 then bled the fuel system in 51 seconds and closed and locked

the cowl in 55 seconds. Engine and transmission accessibility is really outstanding on this design and all engine jobs can be carried out while standing alongside the unit, as opposed to hanging head first over a high front wing. Removal of the engine-transmission unit complete is simple also, and once taken out the engine can be run on its sub-frame when connected to an -external fuel and exhaust system.