Employing Gravity in Tipping.

Page 14

If you've noticed an error in this article please click here to report it so we can fix it.

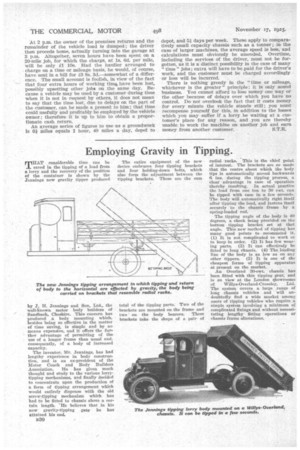

THAT considerable time eau be saved in the tipping of a load from a lorry and the recovery of the position of the container is shown by the Jennings new gravity tipper produced by J. H. Jennings and Son, Ltd., the well-known motor body builders of Sandbach, Cheshire. This concern has produced a body mounting which, besides being so effective in the matter of time saving, is simple and by no means expensive, and it offers the further advantage of permitting of the use of a longer frame than usual and consequently, of a body of increased capacity.

The inventor, Mr. Jennings, has had lengthy experience in body construction, and is an ex-president of the Motor Coach and Body Builders Association. He has given much thought and study to the various lorrytipping mechanisms, and finally decided to concentrate upon the production of a form of tipping arrangement which would entirely dispense with the old screw-tipping mechanism which has had to be fitted to chassis above a certain length. He believes that in his new gravity-tipping gear he has attained his end.

B30 The entire equipment of the new device embraces four tipping brackets and four holding-down bolts, which also form the adjustment between the tipping brackets. These are the sum

total of the tipping parts. Two of the brackets are mounted on the frame and two on the body bearers. These brackets take the shape of a pair of radial racks. This is the chief point of interest. The brackets are so made that the centre about which the body tips is automatically moved backwards 6 ins, during the tipping process, a clear advantage in ease of operation thereby resulting. In actual practice the load from one ton to 30 cwt. can be tipped with ease in a few seconds. The body will automatically right itself after tipping the load, and fastens itself securely to the chassis frame by a spring-loaded rod.

The tipping angle of the body is 40 degrees, a check being provided on the bottom tipping bracket set at that angle. This new method of tipping has many good points to recommend it. (I) It is not complicated to work or to keep in order. (2) It has few wearing parts. (3) It can effectively be fitted to long chassis. (4) The lcholing line of the body is as low as on any other tippers. (5) It is one of the cheapest forms of tipping apparatus at present on the market.

An Overland 30-cwt. chassis has been fitted with this tipping gear, and is on view at the London showrooms of Willys-Overland-Crossley, Ltd. The system covers a large range of long chassis vehicles and will undoubtedly find a wide market among users of tipping vehicles who require a simple system involving a minimum of complicated fixings and without necessitating lengthy fitting operations or chassis frame alterations.