AD MARKET SHOWS UP

Page 128

If you've noticed an error in this article please click here to report it so we can fix it.

• A surprise visitor to the FPS show came in the shape of Charles Roberts Engineering's first tri-axle Lowmax safety tanker, built for Easy Anglian independent, Phoenix Petroleum.

It has been developed and tested to 40 tonnes GCW at MIRA using computer models and strain gauges in the same way as its tandem-axled predecessor for BP.

The aluminium 30,000 litre five compartment Phoenix Lowmax uses CRE's standard system of integral longitudinals which helps to bring the overall height down to 2.990mm.

Its running gear comprises RO-R axles on Hendrickson Norde air suspension (with front lifter), with twin 265/70R 19.5 low profile tyres.

When coupled, its calculated centre of gravity from the ground is 1.6m laden (1.1m unladen).

Unladen, the 11.38m-long tanker weighs around 5.5 tonnes.

The Phoenix tanker is built for bottom loading with vapour recovery and has Drum's latest API-valved manifold system.

Pumping is via a Pluto 3 unit driven by a Hydrapak hydraulic system (also Drummade). CRE is building three new Lowmax models for Petrofina (two triand one tandem-axled versions) to go with BP's trio of tandem-axled tanker semis. Three 30,000 litre Lowmax's are also planned for P&O/Burmah for use at 32.5 tonnes GCW. computerised pump metering package for domestic./ industrial fuel oil delivery companies.

This has been born out of an acquired interest in Danish truck computer firm Sam Systems by a new company jointly owned by Drum and Alfons Haar of Hamburg.

The AD800 can meter from 800 litres/min, down to trickle filling using a small Sam computer with radio link.

Data is received from any suitable office-based system (such as Codas) and used for vehicle routing, deliveries and accounting without the tanker having to return to base.

In addition a cross-over protection option is offered which guards against mixing fuels in storage tanks thus avoiding expensive damage occurring.

For example, catalytic convertors in lead-free engines can be destroyed if leaded fuel is used by mistake.

Integral with the system is Drum's new manifold system for bottom loaders, providing a permanently-connected suction jumper hose.

This is said to reduce discharge time and eliminate the risk of spillage.

The AD800 package which has Weights and Measures and HSE approval retails at around £2,500 for the basic office system and £2,000 per vehicle. Additional management elements can be added.

Drum's managing director John Dunn says that there are many operational benefits that will translate into financial savings.

The first full systems wil be used by Esso and Phoenix Petroleum.

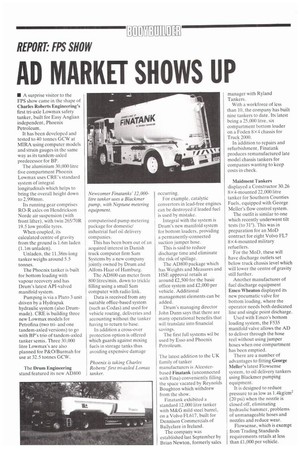

The latest addition to the UK family of tanker manufacturers is Alcesterbased Finatank (unconnected with Fina) conveniently filling the space vacated by Reynolds Boughton which withdrew from the show.

Finatank exhibited a standard 12.000 litre tanker with M&G mild steel barrel, on a Volvo FL617, built for Dennison Commercials of Ballyclare in Ireland.

The company was established last September by Brian Newton, formerly sales manager with Ryland Tankers.

With a workforce of less than 10, the company has built nine tankers to date. Its latest being a 25,000 litre, six compartment bottom loader on a Foden 8x4 chassis for Truck 2000.

In addition to repairs and refurbishment, Finatank produces remanufactured late model chassis tankers for companies wanting to keep costs in check.

Maidment Tankers displayed a Constructor 30.26 8x4-mounted 22,000 litre tanker for Southern Counties Fuels, equipped with George Meller's flow control system.

The outfit is similar to one which recently underwent tilt tests (to 31°). This was in preparation for an MoD contract for eight Volvo FL7 8 x 4-mounted military refuellers.

For the MoD, these will have discharge outlets set below truck chassis level which will lower the centre of gravity still further.

Another manufacturer of fuel discharge equipment Emco Wheaton displayed its new pneumatic valve for bottom loading, where the operator needs both dedicated line and single point discharge.

Used with Emco's bottom loading system, the F535 manifold valve allows the AD to deliver through the hose reel without using jumper hoses when one compartment has been emptied.

There are a number of advantages to fitting George Meller's latest Flowsense system, to oil delivery tankers using Blackmer pumping equipment.

It is designed to reduce pressure to as low as 1.4kg/cm2 (20 psi) when the nozzle is closed off, eliminating hydraulic hammer, problems of unmanageable hoses and nozzles and reduce wear.

Flowsense, which is exempt from Trading Standards requirements retails at less than £1,000 per vehicle.