MOTOR SPIRIT AS A BRITISH PRODUCT.

Page 54

Page 55

If you've noticed an error in this article please click here to report it so we can fix it.

How Motor Spirit is Being Produced by the Cross " Cracking " Process Within an Hour's Journey from London.

JNTEREST " cracked " motor spirit has grown

in this country during the past year or two, for two good reasons. First of all, it is now recognized as one of the solutions of the problem of cheap fuel production, because it is a practical method of utilizing economically for the operation of internal-combustion engines a much larger proportion of the contents of crude petroleum, and secondly the cracking of the distillates of Medium density, such as the paraffin range and gas oil, is now being successfully undertaken in this country, and is having a definite effect upon freedom of supply of motor spirit and upon the price charged to the consumer.

Scientists have emulated the Fat Boy in Pickwick and have tried to make our blood run cold by their predictions of an early or ultimate failure of the oil supply of America. There is no possibility of gain saying them, and to all intents and purposes there is no need to do so, t ii e reasonable attitude to adopt being to encourage the conserva tion of the oil supplies of the world, because there is no evidence that the sources are being replenished.

When, prior to the motor era,

petroleum was

subjected to distillation the most useful product was kerosene or paraffin, used mainly for lighting and heating,

• the range having a specific gravity of approximately .780. In obtaining this paraffin, however, a large quantity of the lighter spirit first came over in the process of distillation and constituted a drug in the market. This spirit was of about .680 sp. gr., and almost the only use found for it was in dry-cleaning. As much as possible of the volatile spirit Was left in the paraffin, and explosions in lamps were of frequent occurrence. With the coming of the motorcar and the growth of the motor movement, the position has so completely changed that the specific gravity of the fuel is no longer a factor to be considered. Any product of petroleum that is capable of being gasified is employed, and the group of distillates which is immediately above the volatile range and which Is too heavy to go through a carburetter can be subjected to a cracking process which makes , it, as it happens, even more useful than the straightrun petrol, because with cracked spirit the compression ratio of an engine can usefully be higher, whilst the user observes, when employing it in ..a normal engine, that he enjoys a freedom from "pinking " or "knocklug," and in consequence has a greater useful range ri-f throttle opening when his vehicle is ascending a gradient.

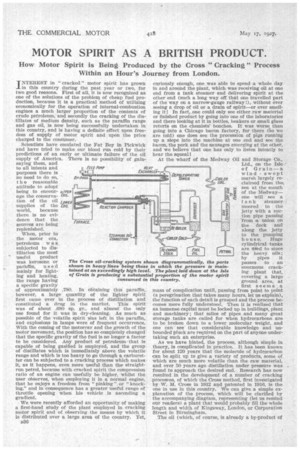

We were recently afforded an opportunity of making. a first-hand study of the plant employed in cracking motor spirit and of observing the means by which it is distributed over a large area of the country. Yet, FEED Pus? By-PAss

tf„.

odPER COIL. REACTIoN CHRINRER COWER COIL FURNACE. StERNIING Our CONNECTION

curiously enough, one was able to spend a whole day in and around the plant, which was receiving oil at one end from a tank steamer and delivering spirit at the other end (such a long way. off that one travelled part of the way on a narrow-gauge railway 0, without ever seeing a drop of oil or a drain of spirit—or ever smelling it ! In fact, one could only see either raw material or finished product by going into one of the laboratories and there looking at it in bottles, beakers or small glass retorts on the chemists' benches. It was worse than going into a Chicago bacon factory, for there ao we are told) one does see the procession of pigs running up a slope into the machine at one end and see the bacon, the pork and the sausages emerging at the other, and we believe that one has only to listen intently to hear the squeal!

At the wharf of the Medway Oil and Storage Co., Ltd., on the Isle of Grain—a wind swept marsh largely reclaimed from the sea at tile mouth of the Medway_ one will see a tank steamer , moored to the jetty with a suction pipe passing from a union on the deck and along the jetty to the pumping house. Huge cylindrical tanks are used to store the heavy oils; by pipes it passes to an enormous cracking plant that, covering a large ground area, at first seems a .mass of complication until, passing from point to point (a peregrination that takes many hours, let us explain), the function of each detail is grasped and the process becomes more fully understood. Then it is realized that an immense capital must be locked up in buildings, plant and machinery ; that miles of pipes and many great storage tanks are called for when hydrocarbons are to be broken down to a lower molecular weight, and one can see that considerable knowledge and unbounded pluck are required on the part of anyone undertaking such an enterprise.

As we have hinted, the process, although simple in theory, is complicated in practice. It has been known for about 120 years that the molecule of hydrocarbon can be split up to give a variety of products, some of which are much more volatile than the raw material, and over 50 years ago distillation under pressure was found to approach the desired end. Research has now resulted in the development of a number of cracking processes, of which the Cross method, first investigated by W. M. Cross in 1912 and patented in 1916, is the one in use in this country. We can give a simple explanation of the process, which will be clarified by the accompanying diagram, representing (let us remind our readers) a plant that would probably fill the whole length and width of Kingsway, London, or Corporation Street in Birmingham.

The oil (which, of course, is already a by-product of

OEPHLEGHATING TOWER. COOLER COIL

e c-, ec ca 14 -801ZEff.

--COMER OILS

RE-ERASE FUEL

STOCK OIL.

the distillation of crude petroleum) is pumped through

• a preheating coil, where it extracts heat from the hot vapours produced in distillation, and passes under a pressure of 700 lb. to the sq. in. into the coils of the vaporizer which are contained in the furnace. The temperature is here raised to 930 degrees Fahr., the charge taking seven minutes to pass through. It emerges into a reaction chamber, which is 42 ft. long, and under the high temperature and the high pressure (which have to be scrupulously maintained) the oil is cracked, the molecules splitting up into the smaller molecules of gas, motor spirit, oils and coke. The oil takes half an hour to pass through the reaction chamber, and in that time one atom of hydrogen is freed and two atoms of carbon are split off, one becoming the coke, which is waste, and the other remaining with the spirit and acting in a curious way. The heated vapour then passes through the dephlegmating tower, where the liquids are reboiled and kept in a state of vaporization. In the vaporizer, where the temperature is about 670 degrees Fahr., a further distillation takes place and the lighter parts are separated, passing to the petrol tanks, and the heavier parts go to the fueloil tank and to one which receives what is known as the recharge stock. These heavier products are mixed with kerosene and are again put through the cracking plant. There. are cooling -and scrubbing sections in the system which need not be explained in detail, and ample use is made in the plant of the gas which cannot be recondensed.

The controls of the system are very wonderful, and the provisions that have to be made for cleaning, and for ensuring the safety of the plant and the workers when" such high pressures and high temperatures are

being employed, excite admiration, but they could not be dealt with adequately in an article of this nature. There are two entirely separate plants used in cracking, because each one has to be shut down at an interval of about 14 days for the removal of the coke—a job that occupies about 12 hours. The keenest possible scrutiny is kept upon the working processes, for the control house, with its gauges and pyrometers, itsqndicators and recording dials, is a veritable heart centre and from it hourly reports are passed to Mr. de Genahl, a man of world-wide experience in oil producing, who is the head and forefront of the undertaking. The laboratories, again, keep a constant cheek upon the raw materials and the products at various stages, because uniformity is regarded as an essential feature of the final product.

The motor spirit is sold under the name of Power petrol in cans or in bulk, being distributed from the two chief depots of the Power Petroleum Co., Ltd., at Charlton and Aylesford, in Kent, and from the subdepots in the Midlands and elsewhere. The output from the plant reached 14,500,000 gallons of petrol last year, and it has since been increased, whilst the plant is being duplicated this year, so that Power petrol makes quite a substantial contribution towards the 500,000,000 gallons of petrol used each year in this country. The general characteristics of the fuel are its reliability and consistency, its high aromatic content (partly arising from the behaviour of that one free atom of carbon to which we have referred), its freedom from knocking, its economy and low price. Generally, we hear very good accounts of it, and it has this further commendation that it is produced by British workers and British capital.