A New Method of Determining Stresses

Page 45

If you've noticed an error in this article please click here to report it so we can fix it.

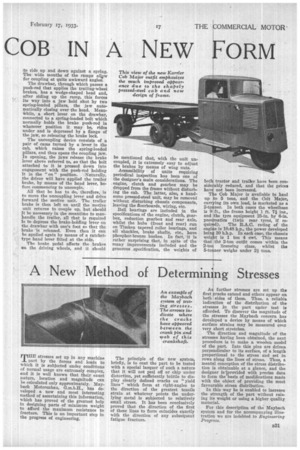

THE stresses set up in any machine part by the forces and loads to which it is subjected under conditions of normal usage are extremely complex, and it is well known that their exact nature, location and magnitude can be calculated only approximately. Mayheel Metorenbau, G.m.b.H., has developed a new and most interesting method of ascertaining this information, which has proved of the greatest help in designing parts of minimum weight to afford the maximum resistance to fracture. This is an important step in the progress of engineering. The principle of the new system, briefly, is to coat the part to be tested with a special lacquer of such a nature that it will not peel off or chip under distortion, yet sufficiently brittle to display clearly defined cracks on "yield lines" which form at right-angles to the direction of the greatest tensile strain at whatever points the underlying metal is subjected to relatively small stress. It has been conclusively proved that the direction of the first of these lines to form coincides exactly with the direction of any subsequent fatigue fracture.

As further stresses are set up the first cracks extend and others appear on both sides of them. Thus, a reliable indication of the distribution of the stresses in the part under test is afforded. To discover the magnitude of the stresses the Maybaeh concern has developed a device by means of which surface strains may be measured over very short stretches.

The direction and magnitude of the stresses having been obtained, the next procedure is to make a wooden model of the part Into this pins are driven perpendicular to its surface, of a length proportional to the stress and set in rows along the linea of stress. Thus, a mental conception of the stress distribution is obtainable at a glance, and the designer isl,provided with precise data to form the basis of modifications made with the object of providing the most favourable stress distribution.

In this way he is enabled to increase the strength of the part without raising it weight or using a higher quality, material.

For this description of the Maybach system and for the accompanying illustration we are indebted to Engineering Progress.