THE NEW 5-TON BERNA LORRY.

Page 16

If you've noticed an error in this article please click here to report it so we can fix it.

'A Well-built Machine, Incorporating the Well-known Berna Features of Side Radius and Torque Members and Internal Gear Final Drive.

BRITISH 13ERNA Motor Lorries, Ltd., have recently received from Switzerland the latest type of SwissBerna. This is a 5-ton machine known as the G.C. model, fitted with a 35-40 h.p.

, engine. It is a fine looking machine, very substantially proportioned, and incorporating many improvements over its predecessors. The frame, which is of rolled channel steel, is perfectly straight and of heavy section. The dumb irons are well set back into the ends of the channels, and a heavy dipped cross member is positioned at the front.

The engine is four-cylindered, with the cylinders cast in pairs, and a bore and stroke of 115 mm. and 160 um.

The speed is governed to 12 m.p.h. on tap gear by means of a centrifugal governor driven by skew gearing.

The crankshaft is mounted on three large diameter ball bearings. Lubrication is on. a simple but effective system. A gear type on pump delivers the oil through nozzles into oil rings on the crankshaft, and from thence it is thrown by centrifugal force through drilled ducts to the big-end bearings. The-oil nozzles a're easily .raccessible for inspection or cleaning, A water-tight magneto and centrifugal water pump are situated on the offside of the engine, the water pump,being bolted to the front of the timing case and the magneto being situated behind the latter. The valves are all on the near side, and enclosed by two covers.

The fan support is screwed into a pillar on the crankcase. The screwed portion of this pillar is split at one side and tightened on to the threads of the fan support by means of a bolt and nut.

A leather-lined. eone clUtch takes the drive through a clutch shaft mounted on ball bearings, universal effect being given by a splined joint. The final connection to the gearbox is by a dog clutch.

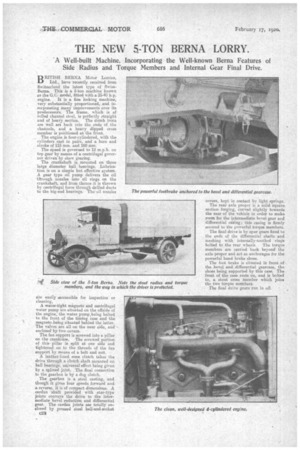

The gearbox is a steel casting, and though it gives four speeds forward and a reverse, it is of compact dimensions. A cardan 'shaft provided with star-type joints conveys the drive to the intermediate bevel reduction and differential gear. The cardan joints are totally enclosed by pressed steel ball-and-socket C.28 covers, kept in contact by light springs. The rear axle proper is a solid square section forging, curved slightly towards the rear of the vehicle in order to mako room for the intermediate bevel gear and differential casing; this easing is firmly secured to the powerful torque members.

The final drive is by spur gears fixed to the ends of the differential shafts and meshing with internally-toothed rings bolted to the rear wheels. The torque members are carried back beyond the axle proper and act as anchorages for the powerful hand brake shoes. The foot brake is situated in front of the bevel and differential gearcase, the shoes being supported by this case. The front of the case rests on, and is bolted to, a stout cross member which joins the two torque members.

The final drive gears run in oil.