Compression Injection

Page 176

If you've noticed an error in this article please click here to report it so we can fix it.

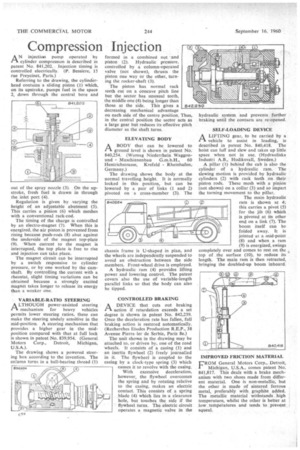

AN injection pump operated by cylinder compression is described in patent No. 841,202. Injection timing is controlled electrically. (P. Bessiere, 15 rue Freycinet, Paris.)

Referring to the drawing, the cylinderhead contains a sliding piston (1) which, on its upstroke, pumps fuel in the space 2, down through the central bore and out of the spray nozzle (3). On the upstroke, fresh fuel is drawn in through the inlet port (4).

Regulation is given by varying the height of an adjustable abutment (5). This carries a pinion (6) which meshes with a conventional rack-rod.

The timing of the charge is controlled by an elect ro-magnet (7). When this is energized, the air piston is prevented from rising because push-rods (8) abut against the .underside of the magnet top-plate (9). When current to the magnet is interrupted, the top plate is free to rise and injection can take place.

The magnet circuit can be interrupted by a switch responsive to cylinder pressure, or by one worked by the camshaft. By controlling the current with a rheostat, slight timing variations can be obtained because a strongly excited magnet takes longer to release its energy than a weaker sine, V ARIA BLE,-RATIO STEERING

LTHOUGH power-assisted steering 1-k mechanism for heavy vehicles permits lower steering ratios, these can make the steering unduly sensitive in the mid-position. A steering mechanism that provides a higher gear in the midposition compared with that at full lock is shown in patent No. 839,954. (General Motors Corp., Detroit, Michigan, U.S.A.).

The drawing shows a powered steering box according to the invention. The column turns in a ball-bearing thread (1)

formed in a combined nut .and piston (2). Hydraulic pressure, controlled by a column-operated valve (not shown), thrusts the piston one way or the other, turning the rocker-shaft (3).

The piston has normal rack teeth cut on a concave pitch line but the sector has unusual teeth, the middle one (4) being longer than those at the side. This gives a decreasing mechanical advantage on each side of the centre position. Thus, in the central position the sector acts as a large gear but reduces its effective pitch diameter as the shaft turns.

ELEVATING BODY

/X BODY that can be lowered to Pl. ground level is shown in patent No. 840,254. (Wumag Niederrhein Waggonmid Maschienenbau G.m.b.H., 60 Hentrichstrasse, Krefeld Rheinhafen, Germany.)

The drawing shows the body at the normal travelling height. It is normally locked in this position, but can be lowered by a pair of links (1 and 2) pivoted on a cross-member (3). The chassis frame is U-shaped in plan, and the wheels are independently suspended to avoid an obstruction between the side members. Front-wheel drive is employed.

A hydraulic ram (4) provides lifting power and lowering control. The patent covers also the use of variable-length parallel links so that the body can also be tipped.

CONTROLLED BRAKING

ADEVICE that cuts out braking action if retardation exceeds a set degree is shown in patent No. 842,239. Once the deceleration rate has fallen, full braking action is restored automatically. (Recherches Etudes Production R.E.P., 38 Avenue Pierre ler de Serbie, Paris 8e.)

The unit shown in the drawing may be attached to, or driven by, one of the road wheels. It consists of a casing (1) and an inertia flywheel (2) freely journalled in it. The flywheel is coupled to the easing by a clock-type spring (3) which causes it to revolve with the casing.

With excessive deceleration, however, the flywheel overcomes the spring and by rotating relative to the casing, makes an electric contact. This consists of a spring blade (4) which lies in a clearance hole, but touches the side if the flywheel turns. The electric circuit operates a magnetic valve in the

hydraulic system and prevents further braking until the contacts are re-opened.

SELF-LOADING DEVICE

I-1 A LIFTING gear, to be carried by a vehicle to assist in loading, is described in patent No. 840,418. The hoist can luff and slew and takes up little space when not in use. (Hydrauliska Industri A.B., Hudiksvall, Sweden.)

A pillar (1) behind the cab is also the cylinder of a hydraulic ram. The slewing motion is provided by hydraulic cylinders (2) with rack teeth on their piston rods. These mesh with a pinion (not shown) on a collar (3) and so impart the turning movement to the pillar.

The main hydraulic ram is shown at 4; this carries a pivot (5) for the jib (6) which is pivoted at its other end on a link (7). The boom itself can be folded away. It is jointed at a .mid-point

(8) and when a ram (9) is energized, swings completely over and comes to rest on the top of the surface (10), to reduce its length. The main ram is then retracted, bringing the doubled-up boom inboard.

IMPROVED FRICTION MATERIAL

FROM General Motors Corp., Detroit, Michigan, U.S.A., comes patent No. 841,817. This deals with a brake mechanism with two shoes made from different material. One is non-metallic, but the other is made of sintered ferrous metal, preferably with graphite added. The metallic material withstands high temperature, whilst the other is better at low ,ternPeratures and tends to prevent squeal.