Greater Power an Whesion for Reiver Models

Page 110

Page 111

Page 112

Page 113

If you've noticed an error in this article please click here to report it so we can fix it.

after the laden fuel-consumption run.

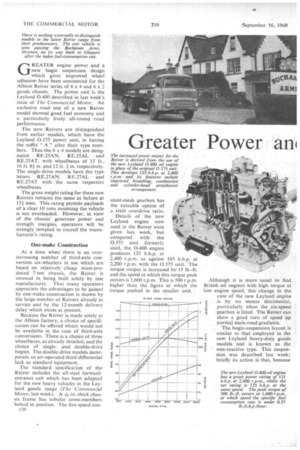

GREATER engine power and a new bogie suspension design which gives improved wheel adhesion have been announced for the Albion Reiver series of 6 x 4 and 6 x 2 goods chassis. The power unit is the Leyland 0.400 described in last week's issue of The Commercial Motor. An exclusive road test of a new Reiver model showed good fuel economy and a particularly lively all-round road performance.

The new Reivers are distinguished from earlier models, which have the Leyland 0.375 power unit, in having the suffix " A ',' after, their type numbers. Thus the 6 x 4 models are designated RE.25AN, RE.25AL and RE.25AT, with wheelbases of 15 ft., 16 ft. 8+ in. and 12 ft. 2 in. respectively. The single-drive models have the type letters RE.27AN, RE.27AL and RE.27AT with the same respective wheel bases.

The gross weight rating for these new Reivers remains the same as before at 154 tons. This rating permits payloads of a clear 10 tons assuming the vehicle is not overloaded. However, in view of the chassis' generous power and strength• margins, operators will he strongly .tempted to exceed the manufacturer's rating.

One-make Construction

At a time when there is an everincreasing number of third-axle conversion six-wheelers in use which are based on relatively cheap mass-produced 7-ton chassis. the Reiver is unusual in being built solely by one manufacturer. That many operators appreciate the advantages to be gained by one-make construction is shown by the large number of Reivers already in service and by the 12-month delivery delay which exists at present.

Because the Reiver is.made solely at the Albion factory, a choice of specification cart be offered which would not be available in the case of third-axle conversions. There is a choice of three wheelbases, as already detailed, and the choice of singleand double-drive bogies. The double-drive models incorporate an air-operated third-differential lock as standard equipment.

The standard specification of the Reiver includes the all-steel forwardentrance cab which has been adopted for the new heavy vehicles in the Leyland goods range (The Commercial Motor, last week). A 15g-in.-thick chassis frame has tubular cross-members bolted in position. The five-speed eon

00 stant-mesh gearbox has the valuable option of a sixth overdrive ratio.

Details of the new Leyland engine now used in the Reiver were given last week, but compared with the 0.375 unit formerly used, the 0.400 engine produces 125 b.h.p. at 2,400 r.p.m. as against 105 b.h.p. at 2,200 r.p.m. with the 0.375 unit. The torque output is increased by 15 lb.-ft. and the speed at which this torque peak occurs is 1,600 r.p.m. This is 500 r.p.m. higher than the figure at which the torque peaked in the smaller unit.

Although it is more 'usual to find British oil engines with high torque at low engine speed, this change in the case of the new Leyland engine 4 • is by no means detrimental,

fparticularly when the six-speed • gearbox is fitted. The Reiver can show a good turn of speed up normal main-road gradients.

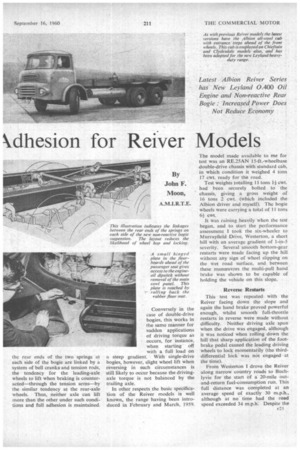

The bogie-suspension layout is similar to that employed in the new Leyland heavy-duty goods models and is known as the non-reactive type. This suspension was described last week; briefly its action is that, because the rear ends of the two springs at each side of the bogie are linked by a system of bell cranks and tension rods, the tendency for the leading-axle wheels to lift when braking is counteracted—through the tension arms—by the similar tendency at the rear-axle wheels. Thus, neither axle can lift more than the other under such conditions and full adhesion is maintained. Conversely in the case of double-drive bogies, this works in the same manner for sudden applications of driving torque as occurs, for instance, when starting off with a full load on a steep gradient. With single-drive bogies, however, slight wheel lift when reversing in such circumstances is still likely to occur because the drivingaxle torque is not balanced by the trailing axle.

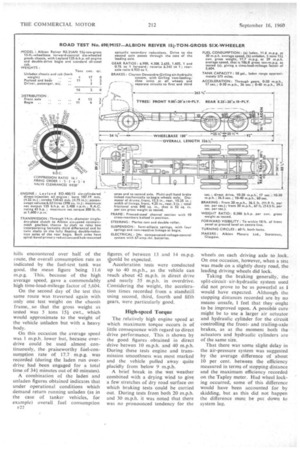

In other respects the basic specification of the Reiver models is well known, the range having been introduced in February and March, 1959. The model made available to me for test was an RE.25AN 15-ft.-wheelbase double-drive chassis with standard cab, in which condition it weighed 4 tons 17 cwt. ready for the road.

Test weights totalling 11 tons 11 cwt. had been securely bolted to the chassis, giving a gross weight of 16 tons 2 cwt. (which included the Albion driver and myself). The bogie wheels were carrying a total of 11 tons 6i cwt.

It was raining heavily when the test began, and to start the performance assessment I took the six-wheeler to Murrayffeld Drive. Westerton, a short hill with an average gradient of 1-in-5 severity. Several smooth bottom-gear restarts were made facing up the hill without any sign of wheel slipping on the wet road surface, and between these manceuvres the multi-pull hand brake was shown to be capable of holding the vehicle on this slope.

Reverse Restarts

This test was repeated with the Reiver facing down the slope and again the hand brake proved powerful enough, whilst smooth full-throttle restarts in reverse were made without difficulty. Neither driving axle spun when the drive was engaged, although it was noticed when rolling down the hill that sharp application of the footbrake pedal caused the leading driving wheels to lock momentarily (the thirddifferential lock was not engaged at the time).

From Westerton I drove the Reiver along narrow conntry roads to Buchlyvie for the start of a 20-mile outand-return fuel-consumption run. This full distance was completed at an average speed of exactly .30 m.p.h., although at no time had the road speed exceeded 34 m.p.h. Despite the hills encountered over half of the route, the overall consumption rate as indicated by the fuel-test tank was good, the mean figure being 11.6 m.p.g. This, because of the high average speed, gave a commendably high time-load-mileage factor of 5,604.

On the second day of the test this same route was traversed again with only one test weight on the chassis frame,. so that the gross weight 8.8 tested was 5 tons 15+ cwt., which would approximate to the weight of the vehicle unladen but with a heavy body.

On this occasion the average speed was 1 m.p.h. lower but, because overdrive could be used almost continuously, the praiseworthy fuel-consumption rate of 17.7 m.p.g. was recorded (during the laden run overdrive had been engaged for a total time of 34+ minutes out of 40 minutes).

A combination of the laden and unladen figures obtained indicates that under operational conditions which demand return running unladen (as in the case of tanker vehicles, for example) overall fuel consumption figures. of between 13 and 14 m.p.g. skould be expected. Acceleration tests were conducted up to 40 m.p.h., as the vehicle can reach about 42 m.p.h. in direct drive and nearly 55 m.p.h. in overdrive. Considering the weight, the acceleration times recorded from a standstill using second, third, fourth and fifth gears, were particularly good.

High-speed Torque The relatively high engine speed at which maximum torque occurs is of little consequence with regard to direct drive performance. This is shown by the good figures obtained in direct drive betwen 10 m.p.h. and 40 m.p.h. During these tests engine and transmission smoothness was most marked and the vehicle pulled away quite placidly from below 9 m.p.h.

A brief break in the wet weather combined with a drying wind to give a few stretches of dry road surface on which braking tests could be carried out. During tests from both 20 m.p.h. and 30 m.p.h. it was noted that there was no pronounced tendency for the wheels on each driving axle to lock. On one occasion, however, when a test was made on a slightly dusty road, the leading driving wheels did lock.

Taking the braking generally, the split-circuit air-hydraulic system used did not prove to be as powerful as I would have expected. Although the stopping distances recorded are by no means unsafe, I feel that they ought to be improved upon. A possible cure might be to use a larger air actuator and hydraulic cylinder for the circuit controlling the frontand trailing-axle brakes, as at the moment both the actuators and hydraulic cylinders are of the same size.

That there was some slight delay in the air-pressure system was suggested by the average difference of about 10 per cent. between the efficiency measured in terms of stopping distance and the maximum efficiency recorded on the Tapley meter. Had wheel locking occurred, some of this difference would have been accounted for by skidding, but as this did not happen the difference must be put down to system lag. Hill-climbing power and brake-faderesistance tests were carried out on Gleniffer Braes, a hill 1.3 miles long with an average gradient of 1 in 13 and sections of up to 1-in-8 severity. The ambient temperature during these tests was 63° F. and before making the climb the engine-coolant temperature was 159° F. The climb lasted only 7 min. 40 sec., which is 10 sec. less than the time taken to climb this gradient • with an Albion Clydesdale last year while running at 14+ tons gross with a Leyland 0.375 engine.

Mhiiinrnn Speed st m.p.h.

The minimum speed during the ascent was 81 m.p.h. Second gear was the lowest ratio employed, having been engaged for a total time of 3 min. 14 sec. The climb caused the coolant temperature to rise by 38° F., which is a little high. The system is pressurized, however, so that the coolant boiling point is 224° F. In normal circumstances there should not, therefore, be any fear of boiling taking place.

As a test for fade resistance, I coasted the Reiver down the slope while using the foot brake to restrict the maximum speed to 20 m.p.h. This descent lasted for 3 min. 36 sec., and a full-pressure stop carried out •at the bottom of the hill from 20 m.p.h. produced a Tapley-meter reading of .34 per cent. This is a drop in efficiency of about 20 per cent., which is very reasonable in view of the length of the descent and the fact that no help was being derived from engine braking. The test caused the off-side front and both near-side rear brakes to smoke heavily.

Revised Steering Layout The Reiver handles very well under all sorts of road conditions and at all speeds. Since the model was originally introduced, the steering layout has been revised so that front-suspension deflection has no effect on the steering. There is a slight but useful degree of castor action and even at walking pace the steering does not become heavy, partly because the gearing is such that six turns of the wheel are required from lock to lock.

The engine performed exceptionally well at all times and never became objectionably noisy. The torque characteristics are particularly pleas

ant from the driver's angle. Fifthgear performance is quite adequate for operation in reasonably heavy traffic, whilst on the open road sharp inclines could be negotiated in sixth gear at speeds down to 20 m.p.h.

Not that use of the gearbox becomes a hardship because, as any driver who has handled this Albion constant

mesh unit will know, it is one of the sweetest designs in current production and permits clutch-less changes to be made either up or down as a matter of course.

Although dampers are not fitted as standard to the front axle and were not installed on the test vehicle, the Reiver rode well when both unladen and laden. Unladen, the steering appears to lose some of its directness, but this is not meant to imply that definite wander occurs.

Although there is no direct linkage between the brake pedal and the wheel units, the pedal has to be pushed fairly hard against a strong reaction spring. However, this helps to give " feel " and so guards against accidental over-application of the brakes when unladen.

"Crash" stops from 30 m.p.h. when unladen were made without taking actual figures and these showed up the non-reactive suspension linkage to its best advantage under this condition. Slight locking and hopping of the leading driving wheels did occur, but this was nowhere 'near as pronounced as is the case with a conventional four-spring-and-balance-beam layout, and the retardation characteristics appeared to be highly commendable.

A full series of maintenance tests was not conducted on this vehicle; for the most part the maintenance will

follow the lines of the current Chieftain and Clydesdale models which have already been tested by The Commercial Motor.

Some maintenance work was done on the new power unit, however, and this showed that with the engine cowl removed the paper element of the Cooper's air cleaner could be removed in 20 sec. and replaced in 25 sec.

To gain access to the fuel injectors it is necessary to remove the valve rocker gear cover, and this took me 1 min. 12 sec. I afterwards took out number 2 injector in 21 min. without undue difficulty and replaced it in 3 min. 20 sec., the only time-waster being the necessity to slacken off the clamping bracket which supports the injection pipes feeding numbers 1, 2 and 3 injectors. With the injector replaced, I re-secured the rocker cover in 1 min. 20 sec.

As a final task I checked the engineoil level in 23 sec. and was gratified to find that it was unnecessary to remove the engine cowl to gain access to the dipstick. This is a recent innovation, which consists merely of the provision of a small swivelling plate in the floor, board on the passenger's side which can be pushed aside once the rubber floor mat has been rolled back, so giving instant access to the handle of the dipstick.