ALL DONE BY PALLET

Page 42

Page 43

Page 44

If you've noticed an error in this article please click here to report it so we can fix it.

Use of Pallets by British Canners, Ltd. Yields "Enormous" Saving in Labour and Space : Articulated Outfits Run Shuttle Service By P. A. C. Brockington,

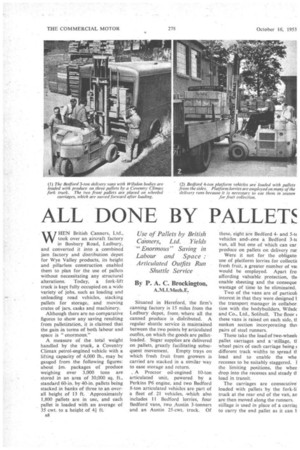

WHEN British Canners, Ltd., took over an aircraft factory in 13osbury Road, Ledbury, and converted it into a combined jam factory and distribution depot for Wye Valley products, its height and pillarless construction enabled them to plan for the use of pallets without necessitating any structural alterations. Today, a fork-lift truck is kept fully occupied on a wide variety of jobs, such as loading and unloading road vehicles, stacking pallets for storage, and moving crates of jars, casks and machinery.

Although there are no comparative figures to show any saving resulting from palletization, it is claimed that the gain in terms of both labour and space is "enormous."

A measure of the total weight handled by the truck, a Coventry Climax petrol-engined vehicle with a lifting capacity of 4,000 lb., may be gauged from the following figures: about Im. packages of produce weighing over 3,000 tons are stored in an area of 30,000 sq. ft., standard 60-in. by 40-in. pallets being stacked in banks of three to an overall height of 13 ft. Approximately 1,800 pallets are in use, and each pallet is loaded with an average of 35 cwt. to a height of 41 ft. Situated in Hereford, the firm's canning factory is 15 miles from the Ledbury depot, from where all the canned produce is dislributed. A regular shuttle service is maintained between the two points by articulated outfits, on which the goods are palletloaded. Sugar supplies are delivered on pallets, greatly facilitating subsequent movement. Empty trays on which fresh fruit from growers is carried are stacked in a similar way to ease storage and return.

A Proctor oil-engined 10-ton articulated unit, powered by a Perkins p6 engine, and two Bedford 8-ton articulated vehicles are part of a fleet of . 21 vehicles, which also includes 11 Bedford lorries, four Bedford vans, two Austin 3-tonners and an Austin 25-cwt. truck. Of

these, eight are Bedford 4and 5-tc vehicles and one a Bedford 3-tc van, all but one of which can car, produce on pallets on delivery run Were it not for the obligato use of platform lorries for collect' fresh fruit, a greater number of vai would be employed. Apart fro affording valuable protection, thi enable sheeting and the conseque wastage of time to be eliminated.

Two of the vans are of particuli interest in that they were designed the transport manager in collabor, tion with the bodybuilders, Wilsdc and Co., Ltd., Solihull. The floor I these vans is raised on each side, ti sunken section incorporating thr4 pairs of steel runners.

These take the load of two-wheel( pallet carriages and a -stillage, ti wheel pairs of each carriage being 4 different track widths to spread tt load and to enable the whe recesses to be suitably staggered. the limiting positions, the whee drop into the recesses and steady a load in transit.

The carriages are consecutive' loaded with pallets by the fork-li truck at the rear end of the van, an are then moved along the runners. stillage is used in place of a carriaf to carry the end pallet as it can I ed exactly in position by the truck. Loading occupies only w minutes, the turn-round time :rally being less than 10 minutes. t the latest pallet-carrying van a ing support is raised under the re of the stillage to transfer some the load from the sides. The ;lit of the payload is, as near as ;ible, kept below the limit recom[tied by vehicle makers.

artons and packages are of angular shape and can be interJed on the pallet to stabilize the 1. Paper is placed between the :rs of 7-lb. jars, which are loaded irately, to act as a packing and tent movement. For transferring the pallets and stillages short distances in the stockrooms, Yale and Towne hand trucks are employed.

Payload is not reduced by the use of pallets, and as it is normal for the produce to be systematically loaded in route-delivery order, no difficulty is experienced by the driver whpri unloading from the rear. When the delivery points cannot be plotted exactly, one of the platform lorries is employed for the run so that the goodscan be unloaded. from the sides. This enables changes in delivery-order to be made by the. driver, bift-thelacilitY is only advantageous in practice when the location a the shops is not known before the start of the run.

Large-scale maps of the delivery areas are closely studied when delivery runs are being Planned. Care taken in map reading, and notes made by the drivers, save any waste in time and mileage.

The area covered from Ledbury includes most of Yorkshire and Lancashire, the Midlands, South Wales, parts of the London area, and all the southern counties between Plymouth and Eastbourne. There are 25 main routes and the average yearly distance covered by each vehicle is between 30,000 and 35,000 miles. Despite the hilly nature of many of the routes the average fuel consumption of the fleet is 10i m.p.g.. The three-tonners average 13 m.p.g.

Distribution depots are planned for certain main areas, and produce will be delivered to them by 10-ton articulated vehicles. Two trailers will enable quick turn-rounds to be made, an empty trailer being left in place of a loaded unit. Goods for eventual redistribution from the depot will be assembled on pallets for easy loading by fork-trucks. The Bedford vehicles fb ver 100,000 to 110,000 miles between engine replacements, new piston rings being fitted at about 65,000 miles. All replacement units are, by agreement with the agents, fitted with cylinder sleeves, but with the exception of twin petrol tanks no other modifications are made to either the . engine or chassis components. The recommended grades of lubricating oil are used, and it is changed every 2,000 miles. It is not filtered for re-use.

Drivers perform routine cleaning, greasing and oiling at week-ends at the garage in Hereford, and each vehicle is checked at least once a month by the mechanics.

The " one-vehicle-one-driver " rule is observed as closely as possible, and drivers are trained to undertake minor repairs. Tyres of various makes are u but all are purchased from the s supplier and they do not fins necessary to keep a stock. Co are inspected by one of the suppi staff at week-ends. He also chi pressures, and makes any necesi changes or replacements. Retrea tyres are not used for the delis vehicles.

The supplier is a member of Tyre Distributors' Associat and in the event of trouble the road the driver calls at nearest member-concern repairs, which are perfort on credit. Good tyre miles are obtained, one vehicle f ing covered 36,000 miles v the same set without a pt. lure, thus proving the econo of giving regular attention tyre equipment.

Use is made of British RI Services' vehicles at the hei of the season, but on aver over 80 per cent. of the r duce is carried by the c cern's own fleet. The sell offered by B.R.S. is conside excellent.