• SUCTION GAS AS A MOTOR FUEL. The Possibilities of the Substitute for Coal-gas for Road Motor Propulsion.

Page 14

Page 15

If you've noticed an error in this article please click here to report it so we can fix it.

THE RESTRICTION UPON the use of coal-gas as a motor fuel has been responsible for a revival of interest in the possibilities of using suction or producer gas as a substitute. The advocates of the principle emphasise the fact that, by using this lower quality gas, it will not only be possible to release coal-gas for more vital duty, but will, furthermore, maintain the young industry which has sprung up for manufacturing the flexible containers. But, there -is another reason which, they maintain should be more than adequate to foster the new development. The production of coal-gas upon an intensified basis, essentially for the extraction of the fundamental constituents of high explosives and fertilisers, is resulting in huge accumulations of the carbon residue. The coke is coming into increasing vogue as a fuel and to a certain degree is displacing, raw coal, but, for the most part; the former fuel is not being consumed from choice. The suction gas enthusiasts point out that, if producer gas were accepted as a fuel for motor vehicles, it would offer a ready and simple means of working off the coke accumulations, and that this could be achieved without exercising anypressing. demand

upon i

. labour, such as is imposed n-the mining and carrying of coal. In other words, 'raw material is

available in abundance. ,

Producer gas is generally accepted as a generic term for all those gases made from coke, anthracite and bituminous coal by the Dowson, Mond and other processes to distinguish it from that generally known as coal or town-gas, although the latter as a matter of fact is a, combination of producer and coal-gas. Suction gas can be satisfactorily employed as a fuel for motors as has been effectively demonstrated to the writer, but it must be pointed out that, as the calorific value of the gas falls, so does the output ofwork from the engine diminish in relation to its standard, which naturally is established by petrol. This difficulty, however' can be overcome by resorting to the enrichment of the suction gas with mineral oil, as is practised by gasworks in regard to town-gas to-day, a but, at the moment, such action would scarcely prove satisfactory from the commercial point of view, owing to the shortage and high price of the essential mineral oil. Nevertheless, despite the high price of the oil, it is probable that the ultimate cost of the enriched suction gas would approximate that of coal-gas, and even such a result would be highly gratifying since it would represent a figure considerably below that ruling for indifferent petrol.

Simplicity of the Producer System.

Certainly, it would be difficult to conceive a more simple method of making gas than that from coke. Simply stated, the process comprises driving a jet of air or steam, or both in certain proportions, through incandescent coke. .

The process is continuous until all the coke is consumed, what is left, if any, being merely clinker, the

air which in forced through the glowing coke supporte ing combustion and restoring the fuel, which becomes cooled by the steam, to its requisite temperature to enable the production process to be efficiently maintamed.

In prefereneee to coke i anthracite coal is often employed, since, with the air blast, it is comparatively easy to keep the fuel at the designed degrees of incandescence. Anthracite is preferred from the fact that it is Cleaner and leaves but little residue, which, if the fuel be of high grade, is-merely an ash. The yield averages about 160,000 cubic ft. per ton of coal, the calorific value being higher than that derived from coke. The cost of production averages

to-day from 4d. to 6d. per 1000 cubic ft. . 038 Of course, the deciding factor is the calorific value of the resultant gas. This may be said to range from . 150 to 400 B.T.O.s. The gas requires from 1i to times its volume of air to bring about complete com

bustion. In using this gas, it is also necessaryto carry out certain modifications in compression moment of ignition and one or two other details which, it might be mentioned, have not received thE measure of attention which they deserve in conjuno ticn with the utilization of coal-gas as a motor fuel.

An Early Vehicle Equipped with a Producer.

The idea of utilizing producer gas for vehicles may be regarded in certain quarters as an innovation, and one-dictated by war-time stringency. But, as a matter of fact, it is entirely free from novelty, having been successfully used in this connection some ten years ago. The experiment then conducted suffered from being premature : the system was satisfactory, but there was no need to worry about suction gas any more than there was any necessity to consider the possibilities of coal-gas as a fuel for motor vehicles, seeing that petrol was relatively cheap, abundant, and a simple fuel to handle. Notwithstanding these latter advantages, suction gas held the field in point of cheapness even in those days.

The experiment in question was conducted with a 40 h.p. char--banes, and the fuel generating unit was complete, the producer, together with its hopper, being placed behind the motor and virtually attached. to the dashboard, so that externally there was little or no indication that the engine was being operated on suction gas. ¶ The installation oecasioned attention from its compactness, its design securing absolutely gas-tightness, and the ingenuity for assuring the correct adjustment of water feed and air blast, as well as the purification details. The producing element, while extending the full width of the chassis within the frame, was 18 ins.. wide and was carried downwards to within 12 ins, of the road level. The grate area was approximately, 12 square ins., with a novel grid for supporting the fuel, and into the centre of whieh the water spray was delivered through four jets or nozzles. The hopper was charged first thing in the morning, one charge sufficing for the day's work. A rotary blower, driven through a chain off the engine crankshaft, maintained the air blast through the bottom of the producer, while the water feed was controlled through an interesting pump of the rotary plunger type, driven off a layshaft. The water feed was automatic in its action and capable of delicate adjustment, the temperature of the fire and the volume of gas produced meeting the precise needs of the engine independently of the driver. This arrangement eonduced to the economical running of the engine, no gas being wasted, for the simple reason that no more gas was generated than the engine required. The producer gas passed from the base of the plant to a coke scrubber suspended beneath the vehicle, then escaped into the mixing chamber where it was associated with air in the correct proportions to form an 'explosive charge preliminary to flowing to the cylinders. The air supply was under the driver's control, a device mounted on the dashboard enabling it to be increased or decreased. So far as the driver . was concerned, the operation of the producer devolved upon a single lever mounted upon the steering column, this enabling the water spray to be adjusted. But, once this was set, the production of the gas proceeded uneventfully, owing to the automatic action of the rotary water pump, so that the gas was of constant-uniformity, irrespective of the speed, load and other adverse conditions prevailing. This novel plant was interesting from the thought

labia had been expended on all details. The hopper . . was sufficiently large to recerya 640 lb. of cokeanthracite pearls were subsequently employed. The plant could be set going in five minutes, charcoal being employed to start the fire., the air blast being arranged to allow hand operation during this process.

The technical trials which were carried out with this vehicle were decidedly enlightening. With anthracite at .14s. 9d. per ton the fuel consumption was approximately .06d. per ton mile as against .67d. per ton .mile on petrol costing is. 24. aper' gallon, showing a savingaper ton mile of .61d. in favour of the producer gas. Even this return could have been improvedaupon had the engine, which was rated at

40 h.p. at 900 revolutions, been fitted with mechanically-operated valves, and had the latter been of double the diameter, experience proving that the existing valve diameter was too small to secure maximum efficiency., The only alteration which had beeramade was in regard to compression, which was set at 115 lb. per sq. In., the trials with the system having indicated such to be the most suitably adapted to this type of fuel. So far as the output of power was concerned, this appeared to be the only noticeable adverse factor, only 30 b.h.p. being possible of attainment on the producer gas..

Can the Experiments be Resumed?

From the experiments which were made ten years ago, it is evident that their resumption in present circumstances is quite warranted. Structurally little variation to the vehicle or motor is required, although, in order to secure the maximum efficiency from this gas, the modifications already mentioned are such as to be advisable. But they do not involve material alteration of the existing type of engine. At the same tithe it is not necessary for vehicles to be equipped With producer gas plants, although such a practice has many features to recommend it, inasmuch as it enables one to go anywhere, coke being a readily obtainable raw material. But, the ability to use this gas would successfully give a new lease of life to the flexible container industry, besides giving additional impetus to the movement in favour of compression, and serve as a means to keep vehicles already fitted with flexible containers in continued operation.

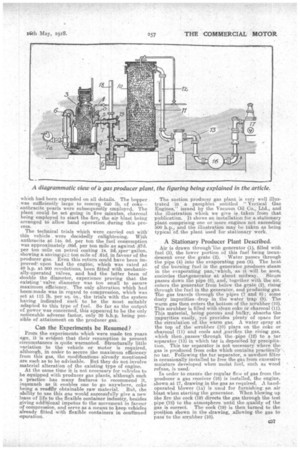

The suction producer gas plant is verY well illustrated in a pamphlet entitled Vertical Gas Engines," issued by the Vacuum Oil Co., Ltd., and the illustration which we give is taken tram that publication. It shows an installation for a stationary plant comprising one or more engines not exceeding 500 .h.p., and the illustration may be taken as being

typical the plant used for stationary work..

A Stationary Producer Plant Described.

Air is drawn throughThe generator (1), filled with fuel (3), the lower portion of this fuel being incandescent over the grate (2). Water passes through the pipe (4) into the evaporating pan (5). The heat of the 'burning fuel in the generator produces steam in the evaporating pane' which, as it will be seen, encircles theagenerator at about midway. Steam passes down the pipe (6), and, together with the air, enters the generator from below the .grate (2), rising through the fuel in the generator, and producing gas. The gas travels through the pipes (7 and 8); some dusty impurities . drop in the water trap (9). The warm gas then enters the bottom of the scrubber (10). This scrubber is filled with clean coke or charcoal (11). This material, being porous and bulky, absorbs the impurities easily, yet provides plenty of space for the circulation of the warm gas. A water spray at the top of the scrubber (10) plays. on the coke or charcoal (11) and cools and purifies the rising gas, which then,passewathrough the ,pipe (12) to a tar separator (13) in which far is deposited by precipitation. This tar separator is not necessary where the gas is produced from coke which contains practically', no tar. Following the tar separator, a sawdust filter is occasionally installed to free the gas from excessive moisture developed when moist fuel, such as wood refuse, is used: In order to ensure the regular flow of gas from, the producer a ga.s receiver (16) is installed, the engine, shown at 17, drawing in the gas as required. A handoperated blower (la) is used for furnishing an air blast when starting the generator. When blowing up the fire the cock (19) directs the gas through the test pipe (18) to the atmosphere until the quality of the gas is correct. The cock (19) is then turned to the position shown in the drawing, ,allowing the gas to pass to the scrubber (10).