UNTING FOR

Page 56

Page 57

If you've noticed an error in this article please click here to report it so we can fix it.

BI GGER PR Y

Hunter Distribution may not court publicity, but it is building a reputation that is winning it some major contracts, including its biggest to date, with Tesco.

• True to its name, Hunter Distribution is a company which has hitherto avoided attention. Its stealth is not due to corporate embarrassment, but to a belief that the prey should be stalked quietly and effectively. Hunter Distribution is gunning for contracts.

Recently the reclusive Hunter has stepped out from its cover to claim its largest quarry so far; the contract to run one of Tesco's national composite retail distribution centres. The centre, based at Harlow, will supply over 5,000 lines on a just-in-time basis. The 21,000m2 warehouse, — the size of 28 football fields — will be split into three sections to deal with ambient, chilled and frozen goods.

Hunter's distribution contracts manager, Chris Dobner says; "In the largest area of the warehouse, the common chilled section, we will be picking by line. We'll receive the goods palletised and pick them straight into roll pallets. Dwell times of chilled products can be just two to three hours." For some delicatessen lines the product will be ordered, harvested, transported, picked and delivered to the stores within hours, not days.

UMPTEEN TENDERS

Operating distribution contracts on such a scale, and at such a pace, is a very demanding and specialised business, yet there is no shortage of stalking companies. "There were umpteen tenders for the Tesco contract," says Dobner, "and 22 companies tendered for the work. Tesco will operate from seven locations with four contractors, and we will be one of the first to start."

He estimates a total of 15 retail distribution centres will be opened in the UK this year. "There are more than six good distribution companies looking for work," he adds.

Dobner has spent over 25 years in the retail distribution business, first with Sainsbury, then with Cory Distribution and, since 1983, with Hunter. It is his responsibility now to raise the profile of Hunter, a change in policy aimed at winning more business. "Up until last year we operated Portway in Faversham, Storeway in Northfleet, Storefresh in St Albans and Storelink at Radlett, and we were quite proud to operate anonymously: however, we are operating at the quality end of the distribution market, so we have raised our profile and changed the livery to green and white." All Hunter Distribution vehicles now operate under the Hunter name — except the Portway vehicles, because of their acceptance at ports.

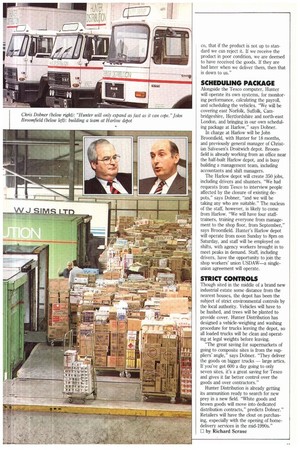

The Hunter's natural instinct for caution still remains, however. "Hunter will only expand as fast as it can cope," says Dobner. "Some contracts are more juicy than others. . . we like to specialise in blue chip companies — were choosy who we work for." Those companies whose contracts have proved acceptable prey for Hunter include Marks and Spencer, Sainsbury and Waitrose.

Hunter's new Tesco contract will be up and running by early next year. The first products will enter the centre by late January, with the first output scheduled for mid-March.

Since the contract began, Hunter Distribution has been charged with designing the building and determining how the work would be carried out. Originally the four contractors were required to put up the capital for each contract themselves, to cover purchase of land, vehicles, trailers and so on. Now, however, Tesco has decided to fund the project itself, under their guidance.

Hunter has adapted its approach to fall in with the new conditions and there are now detailed discussions between it and Tesco, to determine specifications for the contract. On the day before Commercial Motor's visit, the discussion involved the battery charging on the 75 fork-lift trucks needed at the depot. It was decided that this would be controlled by a computer program supplied by one of the battery manufacturers.

Discussions continue regarding the makes of vehicle to be used. "The vehicles have not been purchased yet. It is difficult to answer what makes will be chosen," says Dobner. "There has been a lot of research. Harlow will only need artics operating at 32 tonnes."

Between 40 and 45 tractors will be used on the contract, with contractors brought in to meet peak demand.

There is also some discussion regarding trailer specifications. Hunter Distribution uses a lot of trailers from Gray and Adams, and York, and will use up to 80 trailers on the Tesco contract.

It is likely that certain optional extras like air-suspension, tail-lifts, temperature compartments and wide-single tyres will be specified. "The vehicles will be in Tesco's livery, so our own specifications will not apply," says Dobner.

LIQUID NITROGEN

One interesting option currently being considered is the use of liquid nitrogen as a cooling source in the trailers' refrigerated compartments. "Either you can go for a Petter unit or a Thermoking, or you can go think about it all over again and go for something like liquid nitrogen," says Dobner.

"The fuel is more expensive, but maintenance is reduced to almost zero. There's only one moving part, so the down-time for the trailer is much reduced," he says.

Though exact vehicle choices have yet to be decided, the design of the depot is at a much more advanced stage. The three-section building will have 41 bays for loading and unloading, which will be temperature-controlled according to the section served.

"At other types of compositse they have automation in the warehousing," says Dobner, "but we looked at it for food, and veered away from it. It's not fast and accurate enough. The future is not with automated warehouses, but with control-driven, high-bay warehouses."

Tesco's bar-code-driven computer will control the movements of products within the warehouse. The computer monitors sales at the checkouts in supermarkets, and automatically re-orders the product from the composite centre. If there is insufficient stock there, the computer automatically re-orders from the food manufacturer. By using the bar codes each individual product can be monitored throughout the journey — from production, through transport to the warehouse and picking and so on to distribution to the store. Such detailed stock management improves quality control, says Dobner. "We will run on a first-stock-in firststock-out approach, to ensure the product is as fresh as possible.

"Hunter is authorised, on behalf of Tes co, that if the product is not up to standard we can reject it. If we receive the product in poor condition, we are deemed to have received the goods. If they are bad later when we deliver them, then that is down to us."

SCHEDULING PACKAGE

Alongside the Tesco computer, Hunter will operate its own systems, for monitoring performance, calculating the payroll, and scheduling the vehicles. "We will be covering east Norfolk, Suffolk, Cambridgeshire, Hertfordshire and north-east London, and bringing in our own scheduling package at Harlow," says Dobner.

In charge at Harlow will be John Broomfield, with Hunter for 18 months, and previously general manager of Christian Salvesen's Droitwich depot. Broomfield is already working from an office near the half-built Harlow depot, and is busy building a management team, including accountants and shift managers.

The Harlow depot will create 350 jobs, including drivers and shunters. "We had requests from Tesco to interview people affected by the closure of existing depots," says Dobner, "and we will be taking any who are suitable." The nucleus of the staff, however, is likely to come from Harlow. "We will have four stafftrainers, training everyone from management to the shop floor, from September," says Broomfield. Hunter's Harlow depot will operate from noon Sunday to 8pm on Saturday, and staff will be employed on shifts, with agency workers brought in to meet peaks in demand. Staff, including drivers, have the opportunity to join the shop workers' union USDAW—a singleunion agreement will operate.

STRICT CONTROLS

Though sited in the middle of a brand new industrial estate some distance from the nearest houses, the depot has been the subject of strict environmental controls by the local authority. Vehicles will have to be hushed, and trees will be planted to provide cover. Hunter Distribution has designed a vehicle-weighing and washing procedure for trucks leaving the depot, so all loaded trucks will be clean and operating at legal weights before leaving.

"The great saving for supermarkets of going to composite sites is from the suppliers' angle," says Dobner. "They deliver the goods on bigger trucks — large artics. If you've got 600 a day going to only seven sites, it's a great saving for Tesco and gives it far better control over the goods and over contractors."

Hunter Distribution is already getting its ammunition ready to search for new prey in a new field. "White goods and brown goods will move into dedicated distribution contracts," predicts Dobner." Retailers will have the clout on purchasing, especially with the opening of homedelivery services in the mid-1990s."

by Richard Scrase