PLENTY MOR ROOM ON TOP

Page 31

Page 32

Page 33

Page 34

Page 35

Page 36

If you've noticed an error in this article please click here to report it so we can fix it.

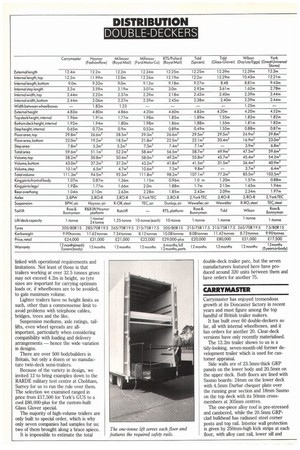

Double-deck semi-trailers have great potential for boosting operational efficiency. We invited a dozen manufacturers to let us take a close look at what they have to offer.

• Over the past five years supermarket chains, mail order companies and express parcel carriers, ever anxious to improve their operating efficiencies, have all shown interest in high-volume double-deck semitrailers.

One of the first to invest in them was Sainsbury which, following the 38-tonne legislation in 1983, spent about £1 million on 30 twin-deckers from RTS. They were part of a new delivery system using special roll pallets that would shift up to 47% more goods and dramatically reduce the number of shop deliveries. The concept of using an otherwise empty roof space is not revolutionary: indeed it was recommended in a Commercial Motor bodywork feature as long ago as February 1937.

The wisdom of it all was apparent at the 1984 Birmingham Motor Show with the appearance of the Belfast-built Wilson Double-Deck trailer. It won few prizes for aesthetics but many admired its twin floor heights and volumes while others spent a deal of time measuring its dimensions.

In response to this interest, other trailer manufacturers have built their own versions to meet their customers' particular needs.

The majority of the twin-deckers are built for general dry-freight distribution but a small number, such as those made by Tidd for Glass Glover's dedicated 6Pak operation, have refrigerated bodywork. Curtain-sided double-deckers are available too, such as those built by Kurtrans for an operator which shifts refuse in special pallets.

Customers specify their split-level trailers to suit their particular operation, but some universal design parameters are linked with operational requirements and limitations. Not least of those is that trailers working at over 32.5 tonnes gross may not exceed 4.2m in height, so tyre sizes are important for carrying optimum loads or, if wheelboxes are to be avoided, to gain maximum volume.

Lighter trailers have no height limits as such, other than a commonsense limit to avoid problems with telephone cables, bridges, trees and the like.

Suspension mediums, axle ratings, taillifts, even wheel spreads are allimportant, particularly when considering compatibility with loading and delivery arrangements hence the wide variation in designs.

There are over 500 bodybuilders in Britain, but only a dozen or so manufacture twin-deck semi-trailers.

Because of the variety in design, we invited 12 to bring examples down to the RARDE military test centre at Chobham, Surrey for us to run the rule over them. The selection we examined ranged in price from £17,500 for York's GUS to a cool 2.80,000-plus for the custom-built Glass Glover special.

The majority of high-volume trailers are only built to special order, which is why only seven companies had samples for us; two of them brought along a brace apiece.

It is impossible to estimate the total double-deck trailer parc, but the seven manufacturers featured here have produced around 320 units between them and have orders for another 75.

CARRMIASTER

Carrymaster has enjoyed tremendous growth at its Doncaster factory in recent years and must figure among the top handful of British trailer makers.

It has built over 60 double-deckers so far, all with internal wheelboxes, and it has orders for another 20. Clear-deck versions have only recently materialised.

The 12.2m trailer shown to us is a tidy-looking, seven-month-old former development trailer which is used for customer appraisal.

Side walls are of 23.5mm-thick GRP panels on the lower body and 20.5mm on the upper deck. Both floors are lined with Sasmo boards: 24mm on the lower deck with 4.5mm Durbar chequer plate over the running gear section and 18mm Sasmo on the top deck with its 50mm crossmembers at 305mm centres.

The one-piece alloy roof is pre-stressed and cambered, while the 20.5rrim GRPclad bulkhead has radiused steel corner posts and top rail. Interior wall protection is given by 250mm-high kick strips at each floor, with alloy cant rail, lower sill and centre extrusions. Full-height double doors are also GRP-pannelled, with a pair of power-brace locks on each side. A 1,000kg Ross and Bonnyman tail-lift is featured, complete with safety rails, twopiece hinged loading edges and a wander lead serving both levels. There are safety barriers at each floor entrance.

The Carrymaster model is built on a stepped "mini-beam" chassis with a BPW tri-axle bogie set at 1.26m axle centres. Automatic slack adjusters, air pressure load sensing and Anchorlock brakes are standard, but the spare wheel carriers incorporated within the side guards are optional extras, along with the Load-lok equipment.

An internal tail-lift is available. The BPW air suspension has a raise/lower capability which will lower the trailer by up to 70mm to allow it to creep under obstacles, and with the air chambers set below the axles it can raise the trailer for wheel changing.

Each floor has headroom of 1.95m and is 2.44m wide. The top deck runs the full 12.2m length while the 9.0m lower deck meets the 0.65m-high, 3.2m-long stepped section.

In standard In-axle form but with two spares fitted, Carrymaster's unladen double-decker weighs in at 9.90 tonnes, and with a 4.83m overall height, its 29.8m.4 and 22.0m.4 main floor areas, and 58.2m3 and 43.0m3 volumes are impressive. The BPW's high neck, 1.92m landing leg-to-king pin clearance and 1.07m pin position are set to suit the high fifth-wheel mounting on a particular Volvo FL10 unit running on 12R x22.5 tyres. On 205/ 8OR x15 tyres, each of the three BPW axles are rated at 6.00 tonnes, with 9.4 tonnes imposed at the king pin.

HOYNOR

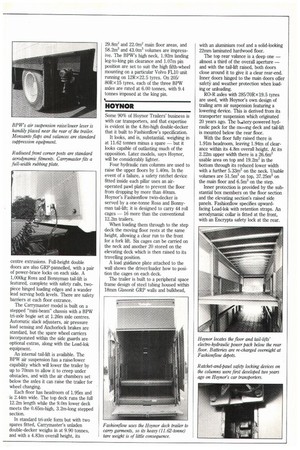

Some 90% of Hoynor Trailers' business is with car transporters, and that expertise is evident in the 4.8m-high double-decker that it built to Fashionflow's specification.

It looks, and is, substantial, weighing in at 11.62 tonnes minus a spare — but it looks capable of outlasting much of the opposition. Later models, says Hoynor, will be considerably lighter.

Four hydraulic ram columns are used to raise the upper floors by 1.40m. In the event of a failure, a safety ratchet device fitted inside each pillar uses an airoperated pawl plate to prevent the floor from dropping by more than 40mm. Hoynor's Fashionflow twin-decker is served by a one-tonne Ross and Bonnyman tail-lift; it is designed to carry 44 roll cages — 16 more than the conventional 12.2m trailers.

When loading them through to the step deck the moving floor rests at the same height, allowing a clear run to the front for a fork lift. Six cages can be carried on the neck and another 20 stored on the elevating deck which is then raised to its travelling position.

A load guidance plate attached to the wall shows the driver/loader how to position the cages on each deck.

The trailer is built to a peripheral space frame design of steel tubing housed within 18nirn Glasonit GRP walls and bulkhead, with an aluminium roof and a solid-looking 22mm laminated hardwood floor.

The top rear valance is a deep one — almost a third of the overall aperture — and with the tail-lift raised, both doors close around it to give it a clear rear-end. Inner doors hinged to the main doors offer safety and weather protection when loading or unloading.

RO-R axles with 285/70Rx19.5 tyres are used, with Hoynor's own design of trailing arm air suspension featuring a lowering device. This is derived from its transporter suspension which originated 20 years ago. The Litery-powered hydraulic pack for the moving deck and tail-lift is mounted below the rear floor.

With the floor fully raised there is 1.91m headroom, leaving 1.94m of clearance within its 4.8m overall height. At its 2.22m upper width there is a 26.6m2 usable area on top and 19.2m2 in the bottom through its reduced lower width with a further 5.33m2 on the neck. Usable volumes are 51.5m3 on top, 37.25m3 on the main floor and 6.5m3 on the step.

Inner protection is provided by the substantial box members on the floor section and the elevating section's raised side panels. Fashionflow specifies upwardfacing Load-lok with retention straps. An aerodynamic collar is fitted at the front, with an Encrypta safety lock at the rear.

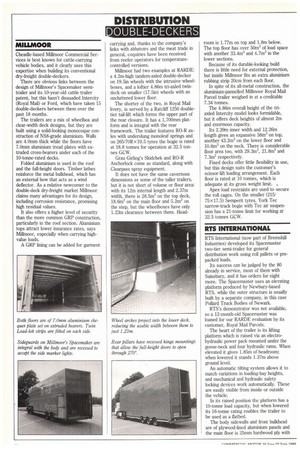

MI LLMOOR

Cheadle-based Millmoor Commercial Services is best known for cattle-carrying vehicle bodies, and it clearly uses this expertise when building its conventional dry-freight double-deckers.

There are obvious links between the design of Millmoor's Spacemaker semitrailer and its 10-year-old cattle trailer patent, but this hasn't dissuaded Intercity (Royal Mail) or Ford, which have taken 15 double-deckers between them over the past 18 months.

The trailers are a mix of wheelbox and clear-width deck designs, but they are built using a solid-looking monocoque construction of NS8-grade aluminium. Walls are 4.0min thick while the floors have 7.0mm aluminium tread plates with extruded cross-bearers under each of the 10-tonne-rated decks.

Folded aluminium is used in the roof and the full-height doors. Timber lathes reinforce the metal bulkhead, which has an external bow that acts as a wind deflector. As a relative newcomer to the double-deck dry-freight market Millmoor claims many advantages for its design, including corrosion resistance, promising high residual values.

It also offers a higher level of security than the more common GRP construction, particularly in the roof section. Aluminium tops attract lower insurance rates, says Millmoor, especially when carrying highvalue loads.

A GRP lining can be added for garment carrying and, thanks to the company's links with abbatoirs and the meat trade in general, enquiries have been received from reefer operators for temperaturecontrolled versions.

Millmoor had two examples at RARDE: a 4.2m-high tandem-aided double-decker on 19.5in wheels with the intrusive wheelboxes, and a loftier 4.86m tri-axled twindeck on smaller (17.51n) wheels with an uncluttered lower floor.

The shorter of the two, in Royal Mail livery, is served by a Ratcliff 1250 doubletier tail-lift which forms the upper part of the rear closure. It has a 1,700mm platform and is integral with the rear framework. The trailer features RO-R axles with underslung monoleaf springs and on 265/70R x19.5 tyres the bogie is rated at 18.8 tonnes for operation at 32.5 tonnes GCW.

Grau Girling's Skidchek and RO-R Anchorlock come as standard, along with Clearpass spray equipment.

It does not have the same cavernous dimensions as some of the taller trailers, but it is not short of volume or floor area: with its 12m internal length and 2.37m width, there is 28.5m2 on the top deck, 18.6m2 on the main floor and 5.2m2 on the step, but the wheelboxes have only 1.23m clearance between them. Head room is 1.77m on top and 1.8m below. The top floor has over 50m3 of load space with another 33.4m3 and 4.7m3 in the lower sections.

Because of its durable-looking build there is little need for external protection, but inside Millmoor fits an extra aluminium rubbing strip 20cm from each floor.

In spite of its all-metal construction, the aluminium-pannelled Millmoor Royal Mail Parcel trailer weighed in at a creditable 7.34 tonnes.

The 4.86m overall height of the triaxled Intercity model looks formidable, but it offers deck heights of almost 2m and enormous capacity.

Its 2.39m inner width and 12. 26m length gives an expansive 58m3 on top, another 43. 2m on the lower floor and 10.6m3 on the neck. There is considerable floor area too, with 29.3m2, 21.8m2 and 7.3m2 respectively.

Fixed decks offer little flexibility in use, but this design suits the customer's scissor-lift loading arrangement. Each floor is rated at 10 tonnes, which is adequate at its gross weight limit.

Apex load restraints are used to secure the roll cages. On the smaller (215/ 75x17.5) Semperit tyres, York Tec narrow-track bogie with Tec air suspension has a 21-tonne limit for working at 32.5 tonnes GCW.

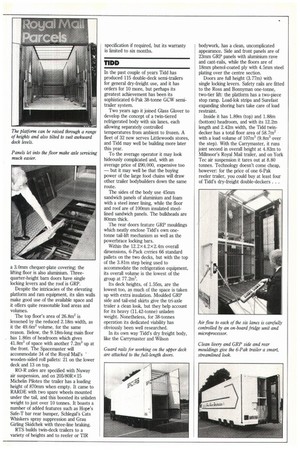

RTS IMIRPIATIONAL

RTS International (now part of Bremshill Industries) developed its Spacemaster two-tier semi-trailer for general distribution work using roll pallets or prepacked loads.

Its success can be judged by the 80 already in service, most of them with Sainsbury, and it has orders for eight more. The Spacemaster uses an elevating platform produced by Newbury-based RTS, while the outer structure is usually built by a separate company, in this case Pollard Truck Bodies of Newark.

RTS's demonstrator was not available, so a 12-month-old Spacemaster was loaned for our RARDE evaluation by its customer, Royal Mail Parcels.

The heart of the trailer is its lifting platform which is raised via an electrohydraulic power pack mounted under the goose-neck and four hydraulic rams. When elevated it gives 1.85m of headroom; when lowered it stands 1.37m above ground level.

An automatic tilting system allows it to match variations in loading-bay heights, and mechanical and hydraulic safety locking devices work automatically. These are easily visible from inside or outside the vehicle.

In its raised position the platform has a 10-tonne load capacity, but when lowered its 16-tonne rating enables the trailer to be used as a flatbed.

The body sidewalls and front bulkhead are of plywood-lined aluminium panels and the main floor is 25mm hardwood ply. with a 3.0mm chequer-plate covering; the lifting floor is also aluminium. Threequarter-height barn doors have single locking levers and the roof is GRP.

Despite the intricacies of the elevating platform and ram equipment, its slim walls make good use of the available space and it offers quite reasonable load areas and volumes.

The top floor's area of 26.8m2 is lessened by the reduced 2.18m width, as it the 49.6m3 volume, for the same reason. Below, the 9.18m-long main floor has 1.86m of headroom which gives 41.8m3 of space with another 7.2m3•up at the front. The Spacemaster will accommodate 34 of the Royal Mail's ' wooden-sided roll pallets: 21 on the lower deck and 13 on top.

RO-R axles are specified with Nuway air suspension, and on 205/80R x15 Michelin Pilotes the trailer has a loading height of 870mm when empty. It came to RARDE with two spare wheels mounted under the tail, and this boosted its unladen weight to just over 10 tonnes. It boasts a number of added features such as Hope's Safe-T bar rear bumper, Schlegal's Cats Whiskers spray suppression and Grau Girling Skidchek with three-line braking.

RTS builds twin-deck trailers to a variety of heights and to reefer or TIR specification if required, but its warranty is limited to six months.

TIDD

In the past couple of years Tidd has produced 115 double-deck semi-trailers for general dry-freight use, and it has orders for 10 more, but perhaps its greatest achievement has been its sophisticated 6-Pak 38-tonne GCW semitrailer system.

Two years ago it joined Glass Glover to develop the concept of a twin-tiered refrigerated body with six lanes, each allowing separately controlled temperatures from ambient to frozen. A fleet of 32 now serves Littlewoods stores, and Tidd may well be building more later this year.

To the average operator it may look hideously complicated and, with an average price of 290,000, expensive too — but it may well be that the buying power of the large food chains will draw other trailer bodybuilders down the same route.

The sides of the body use 45mm sandwich panels of aluminium and foam with a steel inner lining, while the floor and roof are of 100mm insulated steellined sandwich panels. The bulkheads are 80mm thick.

The rear doors feature GRP mouldings which neatly enclose Tidd's own onetonne tail-lift mechanism as well as the powerbrac,e locking bars.

Within the 12. 2 x 4.2 x 2.4m overall dimensions, 6-Pack carries 66 standard pallets on the two decks, but with the top of the 3.81m step being used to accommodate the refrigeration equipment, its overall volume is the lowest of the group at 77.2m3.

Its deck heights, of 1.55m, are the lowest too, as much of the space is taken up with extrainsulation. Moulded GRP side and tail-end skirts give the tri-axle trailer a clean look, but they help account for its heavy (11.42-tonne) unladen weight. Nonetheless, for 38-tonnes operation its dedicated viability has obviously been well researched.

In its own way Tidd's dry freight body, like the Carrymaster and Wilson bodywork, has a clean, uncomplicated appearance. Side and front panels are of 23mm GRP panels with aluminium rave and cant-rails, while the floors are of 18rnm phenol-coated ply with 4.5mm steel plating over the centre section.

Doors are full height (3.77m) with single locking levers. Safety rails are fitted to the Ross and Bonnyman one-tonne, two-tier lift: the platform has a two-piece stop ramp. Load-lok strips and Surefast expanding shoring bars take care of load restraint.

Inside it has 1.89m (top) and 1.88m (bottom) headroom, and with its 12.2m length and 2.42m width, the Tidd twindecker has a total floor area of 58.7m2 with a load volume of 107m3 (9.8m3 over the step). With the Carrymaster, it runs joint second in overall height at 4.83m to Millmoor's Royal Mail trailer, and on York Tec air suspension it tares out at 8.80 tonnes. Technology doesn't come cheap, however: for the price of one 6-Pak reefer trailer, you could buy at least four of Tidd's dry-freight double-deckers. . .

WILSON

One of the pioneers of the twin-tiered bodywork concept is Wilson Double-Deck Trailers, which has over 100 in operation with retailers and distributors around Britain, with another 20 or so in the pipeline. The trailers are of monocoque construction, using 1.0mm high-tensile Zalutite (aluminium-coated) steel panels which are fabricated in a forming mill at the Wilson factory in Craigavon, Northern Ireland.

Both floors use the same steel panels as the sides, roof and bulkhead, but they are re-inforced with wooden battens which are sealed in a heated press.

Wilson offers a choice of its own side, tail or internal hydraulic lifts. The onetonne version shown uses heavy-duty fork-lift chains instead of wire cables, and the platform (which can be made in lengths up to 2.44m) is opened and closed hydraulically. Lift cylinders on each side operate in unison and a powered ramp plate eases dock-loading and unloading, as well as acting as a cage stop.

On the upper deck there is a hinged roll-cage barrier, and when loaded the lift forms the door for the upper floor, leaving the half-height steel-sheet barn doors to close off the lower part.

With 19.5in wheels, RO-R axles and steel suspension, and within the trailer's overall height of 12.2m, there is 1.82m clearance on top and 1,81m below to the neck. Only Millmore's aluminium Royal Mail parcel carrier can improve on that; it is 1.34 tonnes lighter to boot.

With a floor area of 24.3m2 on top, 16.90 on the main floor (allowing for the wheelboxes) and 3.9m2 on the step, the Wilson trailer gives a total volume of 85.5m3 compared with the Millmoor's 92.3m3.

RO-R Anchorlok and Grau Girling Skidchek are fitted as standard to axles that are rated at 9.4 tonnes apiece. A compartment at the front end of the top floor houses spare wheels and the power pack for the hydraulics.

Wilson offers a choice of suspensions, with body heights up to 4.4m. It has also developed a twin-decker that uses a movable 12.2m middle floor which can be adjusted vertically in 100mm increments to suit operators carrying products of two different heights.

Wilson has also built a side-opening double-decker for fork-lift loading which uses hinged side-opening doors and lifting upper sides. At 38 tonnes the semi-trailer will carry 35 metric pallets at up to 1.8m high, and offers good load security,

YORK

At first glance Great Universal Stores' double-decker has an unfinished look about it. It has a high rear ledge and, without an external tail-lift, looks impossible to load.

GUS's Manchester-based vehicles, however, operate from buildings with oldfashioned loading ramps, so it is cheaper to adapt new vehicles than to build new warehouses; hence the twin-decked 12.2m semi-trailer.

York has built 10 double-deckers for GUS to date, all based on its standard Freighttnaster 2000 design. It features 1.6nun aluminium sidewalls and bulkheads of 150nun-pitch ribbed panels, supported by channel uprights. The floor is hardwood ply with a chequered tread plate. GUS's use of the one-tonne Ross and Bonnyman internal fixed-floor platform is dictated by its loading bays, which match the height of the rear ledge. The platform serves each deck and has a safety net beneath it to prevent mishaps.

Each floor is 1.82m high, giving it a top floor area on a par with Carrymaster's loftier double-decker, but losing out on the lower floor because of the step length. Its total volume is smaller than those of the taller trailers, but at 102.5m3 it is better than most.

On price it is out on its own, being £3,500 cheaper than the Wilson trailer, and at 7.40 tonnes unladen it gives a reasonable payload too. With Tec axles and suspension, the York semi-trailer is pretty much a total package, which is probably one of the reasons why GUS runs such a large fleet of Freightmasters.

by Bryan Jarvis