UNDERNEATH THE ARCHES

Page 149

Page 150

If you've noticed an error in this article please click here to report it so we can fix it.

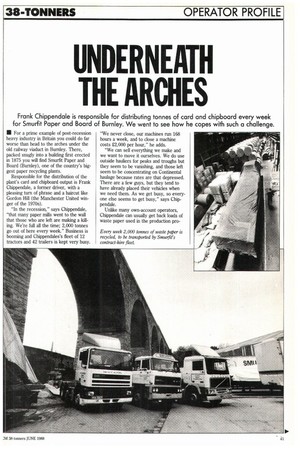

Frank Chippendale is responsible for distributing tonnes of card and chipboard every week for Smurfit Paper and Board of Burnley. We went to see how he copes with such a challenge.

• For a prime example of post-recession heavy industry in Britain you could do far worse than head to the arches under the old railway viaduct in Burnley. There, packed snugly into a building first erected in 1875 you will find Smurfit Paper and Board (Burnley), one of the country's biggest paper recycling plants.

Responsible for the distribution of the plant's card and chipboard output is Frank Chippendale, a former driver, with a pleasing turn of phrase and a haircut like Gordon Hill (the Manchester United winger of the 1970s).

"In the recession," says Chippendale, "that many paper mills went to the wall that those who are left are making a killing. We're full all the time; 2,000 tonnes go out of here every week." Business is booming and Chippendales's fleet of 12 tractors and 42 trailers is kept very busy. "We never close, our machines run 168 hours a week, and to close a machine costs £2,000 per hour," he adds.

"We can sell everything we make and we want to move it ourselves. We do use outside hauliers for peaks and troughs but they seem to be vanishing, and those left seem to be concentrating on Continental haulage because rates are that depressed. There are a few guys, but they tend to have already placed their vehicles when we need them. As we get busy, so everyone else seems to get busy," says Chippendale.

Unlike many own-account operators, Chippendale can usually get back loads of waste paper used in the production pro cess at the Burnley plant. In total, around 800 tonnes of the weekly requirement of 1,600 tonnes of waste paper is brought in by Smurfit trucks.

To cope with current demand Chippendale operates all his vehicles at 38 tonnes, and relies on contract hire to provide him with a modern, well maintained and reliable fleet. Even the company's hardpressed shunting vehicle, a much-modified Volvo F7, is supplied on contract hire. "We get reliability with all our vehicles on contract hire," he says, "They are replaced every two to three years so we expect reliability and we've never had any major problems."

All the tractor units and many of the trailers are supplied by Salford Van Hire. "I have built up a personal relationship with Bacci and Martini at Salford Van Hire, which goes back 10 years," says Chippendale. "Back then we were running our own fleet down and using contractors. There was a strike, so we hired some vehicles — Volvo FlOs — from Salford. Our drivers were in heaven after their old Bedford TKs and Ford D series. We eventually got rid of all the vehicles and everything is now contract-hired."

Contract hire

One of the advantages of acquiring vehicles on contract hire is the flexibility it allows in trying new vehicles. In the depths of the recession, when the 38tonne weight limit was introduced, Chippendale decided to uprate his fleet to the new weight limit. Initially, the company plumped for two-axle tractors and tri-axle trailers, but there were considerable tyrewear problems on the trailers. "We were fined £250 for overloading on one axle, even though the vehicle weighed exactly 38,000kg," says Chippendale, "so we changed the fleet around and, touch wood, we don't have a problem on loading any more."

Salford agreed to exchange Smurfit's fleet for three-axle tractors, at a price no higher than the existing fleet. Chippendale had to accept vehicles which were not brand new, but Salford's flexibility at the time was a favour which he has not forgotten.

Now Smurfit has a policy of reviewing its tractors after two years on the road. Chippendale will negotiate with Salford Van Hire if he wants to keep the vehicle for perhaps a further six or twelve months.

The fleet consists of three Scanias, four Volvos and five Leyland Dafs. Six weeks ago Smurfit took delivery of two twinsteer Leyland Daf 95-series tractors and Chippendale is very impressed. "You always have variations on mileage depending on the drivers, but we've had 8.4mpg and 8mpg on the 95-series." With Chippendale's benchmark of around 38 litres/ 100km (7.5mpg) this represents very good economy for the 1.6 million kilometres the fleet travels each year.

"We let our drivers have a say in the choice of vehicle, and they have a great loyalty to marques. If we're getting over 7mpg (40.361/100km) with the trucks we're quite happy, but if we're getting over 8mpg (35.311/100km) in a British truck, then we will lean harder on the drivers."

A further two 95-series are due on 1 August, but so far Chippendale has not had to lean on his drivers. "Our drivers won't come out of the 95-series, they absolutely love them. It really seems like a new move in trucking — the drivers say its like driving a coach. I don't know why but they (Leyland Daf) seem to have got it right. . . I would be surprised in the next four or five years if I haven't got 11 or 14, or even 15 of the 95s in the fleet."

The drivers like the handling of the twin-steer tractor, and Chippendale reports no problems with the arrangement. This contrasts with an eight-speed Volvo tractor in the fleet, which is about to be dropped because of poor fuel consumption and problems with its lifting back axle, and the Mercedes-Benz tractors which Chippendale has already phased out because of their poor average (43 litres/100km) consumption.

All the tractor units in the Smurfit (Burnley) fleet are checked every five weeks by Salford. Replacement vehicles are provided while the Smurfit units are off the road. "I used to have to run at night to get gearboxes from Watford for my Scammell Crusaders," says Chippendale. "Now I pay Salford Van Hire for taking all that hassle away."

Smurfit's trailers are also supplied on contract hire, by both Salford Van Hire and TIP. The all-tandem-axle trailer fleet is split between 25 flat trailers and 17 Boalloy Tautliners. "Some customers can't accept Tautliners, because they need to unload using overhead cranes, but most industries are moving to curtainsiders," says Chippendale. "There's something of a bulk move to curtainsiders on our fleet, but it's getting the customer to accept them.

"On flats, the paper reels are always belly-stacked; on Tautliners, they are endstacked. Customers staff have to go out into the wet and cold to unload, rather than staying in the warm and using the overhead crane.

"With our mill we've got a growing problem with the loading bay. It was built in 1875 for the horse and cart and we haven't enough loading bays. That's one reason we've gone for Tautliners — if you get the paper or card wet, its ruined. . . here it rains 371 days a year, so we tried a couple of Tautliners, and found we were getting a quicker turnaround, and protecting the goods, keeping them dry."

Since the introduction of the Tautliners, Chippendale has found Salford Van Hire far happier to livery the trailers in Smurfit colours. "Salford agreed to put our liveries on the tautliners when we decided they were a good way of advertising our company."

Good relationship

Chippendale says he is happy to talk to other contract hire companies. "If a guy wants to knock on the door, I will discuss it with him," he says. "I've got a good relationship with Salford, but I have to do my best for Smurfit& I'm a believer in sticking with the people I've built a relationship with. SVH is not perfect — they let me down once in 10 years, when they couldn't get me what I wanted — one more time and their out," he adds, with a wry grin.

Though the vehicles are hired in, the 11 full-time and four part-time drivers are all long-term employees, who have developed through the company. "We don't use agency drivers — we like to use hand-picked men," says Chippendale, "We start them at 16 and put them through loading and sheeting, then shunting and then through Class 1 HGV when they are old enough. Our drivers do not leave. What they do is like a five-year apprenticeship; as trained guys they do exactly what you want them to.

"We have a waiting list to get on here," he adds. "In the Burnley area we operate one of the best fleets — its one of the newest, with the most desirable vehicles, and we pay good money as well."

The new drivers' hours legislation has introduced greater flexibility for the Smurfit fleet. "It costs us more, though, because the drivers are doing more hours, but are able, with the new machines and the motorways (providing they are clear), to do a hell of a lot more work."

Chippendale is currently considering fitting his trucks with speed limiters to improve fuel consumption. "Some of our drivers drive in ballet pumps, while others drive in diving boots", he says, "Speed limiters are something I'd like to look at — it's good for the company image."