REM STAMP of APliNAP

Page 42

Page 43

If you've noticed an error in this article please click here to report it so we can fix it.

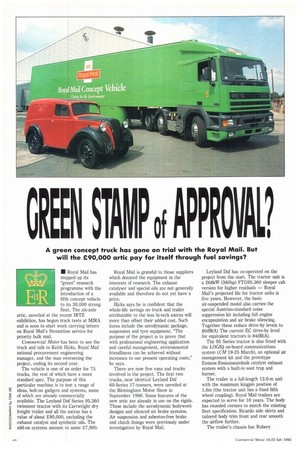

A green concept truck has gone on trial with the Royal Mail. But will the E90,000 artic pay for itself through fuel savings?

EIR

• Royal Mail has stepped up its "green" research programme with the introduction of a fifth concept vehicle to its 30,000 strong fleet. The six-axle artic, unveiled at the recent IRTE exhibition, has begun track tests at MIRA and is soon to start work carrying letters on Royal Mail's Streamline service for priority bulk mail.

Commercial Motor has been to see the truck and talk to Keith Hicks, Royal Mail national procurement engineering manager, and the man overseeing the project, ending its second year.

The vehicle is one of an order for 75 trucks, the rest of which have a more standard spec. The purpose of this particular machine is to test a range of ideas, bolt-on gadgets and systems, some of which are already commercially available. The Leyland Daf Series 95.360 twinsteer tractor with its Cartwright dry freight trailer and all the extras has a value of about £90,000, excluding the exhaust catalyst and synthetic oils. The add-on systems amount to some £7,900. Royal Mail is grateful to those suppliers which donated the equipment in the interests of research. The exhaust catalyser and special oils are not generally available and therefore do not yet have a price.

Hicks says he is confident that the whole-life savings on truck and trailer attributable to the less hi-tech extras will more than offset their added cost. Such items include the aerodynamic package, suspension and tyre equipment. "The purpose of the project is to prove that with professional engineering application and careful management, environmental friendliness can be achieved without increases to our present operating costs," he says.

There are now five vans and trucks involved in the project. The first two trucks, near identical Leyland Daf 60-Series 17-tonners, were unveiled at the Birmingham Motor Show in September 1990. Some features of the new artic are already in use on the rigids. These include the aerodynamic bodywork designs and silenced air brake systems. Air suspension and asbestos-free brake and clutch linings were previously under investigation by Royal Mail. Leyland Daf has co-operated on the project from the start. The tractor unit is a 268kW (360hp) FTG95.360 sleeper cab version for higher residuals — Royal Mail's projected life for tractor units is five years. However, the basic air-suspended model also carries the special Austrian-standard noise suppression kit including full engine encapsulation and air brake silencing. Together these reduce drive-by levels to 80dB(A) The current EC drive-by level for equivalent tractors is 84dB(A).

The 95 Series tractor is also fitted with the LOGIQ on-board communications system (CM 19-25 March), an optional air management kit and the prototype Erninox-Emissionsteknik catalyst exhaust system with a built-in soot trap and burner.

The trailer is a full-length 13.6-m unit with the maximum kingpin position of 1.6m (the tractor unit has a fixed fifth wheel coupling). Royal Mail trailers are expected to serve for 10 years. The body has rounded corners to match the existing fleet specification. Ricardo side skirts and tailored body trim front and rear smooth the airflow further.

The trailer's chassis has Rubery Owen-Rockwell Indair air suspension with a rear lift capability. SAF's axle weight indication system, signals each axle's working suspension pressure. Simple pressure gauges are sited on the left side; they are calibrated in tonnes, though Hicks says he would prefer a simple Go/No-Go indicator for drivers.

The same system is fitted to the tractor's drive axle. As the coupling is fixed, the system can give an indication of the tractor's gross weight.

Each of the Pirelli tyres is fitted with Pirelli's Tyrewatch radio-based warning system. This alerts the driver to any 10% pressure drop via an in-cab display.

The other individual systems on the vehicle read like an over-funded fleet engineer's Christmas list. Hicks accepts that not every product suits every vehicle, but when your fleet covers 1.6 million miles every working day it makes sense to investigate every possibility.

Stability is under test with a Hope anti-jack-knife device attached to the kingpin. Safety while reversing is further enhanced with a Sens-n-Stop retractable rear underrun bar. Category One ABS is fitted on every axle and spray suppression equipment has been liberally applied to the underside of the trailer.

Rearward visibility is helped by a Back-Eye rearview camera system.

Simple electrical failures, usually bulbs, account for some of the greatest maintenance costs on trailer fleets, says Hicks. A blown bulb also represents the simplest repair and the greatest potential for disaster, so he has taken the opportunity to test Trucklite's new rear light cluster range imported from the US.

At 8.86 tonnes the trailer has been kept as light as possible while staying within Royal Mail's spec for toughness. As Hicks explains, all the concept vehicles are subjected to the full rigours of fleet life, so they need to be hardy. The Streamline service uses palletised loads which can be fork-lifted aboard, so 300mm crossmember centres have been retained below a softwood floor. Softwood is under test for environmental reasons, says Hicks. It is lighter, and the trees grow more quickly than hardwood. The only question is: will it last?

To speed up loading and improve the driver's lot an air-operated open and close mechanism has been fitted to the Whiting rear roller shutter door. Now the press of a button closes the door in seconds.

Synthetic oils as well as bio-degradable greases in the automatic chassis lubrication systems of both truck and trailer ensure the green thenle is literally carried through to all areas, Hicks says the part-synthetic lubricants may prove the greenest innovation of all, due to the problems of disposing of totally man-made products.

He believes that with the potential to save up to 15% in fuel and tyre savings alone, such a truck must pay for itself. But in what length of time? The environmental considerations are ones which he feels the larger fleets have responsibility to investigate, not least because everyone knows the small fleets don't have the time or the money. There are sound fleet management reasons, too: "This truck gets us closer to our customers and the manufacturers," he says. "By working in conjunction with people like Leyland Daf we Can improve our fleet from the outset."

Hicks believes that the real savings will come by combining this research with Royal Mail's driver training programme Maildrive, and with computerised traffic scheduling systems such as its own Trandos. With its aim of improving fleet use by 20% this system alone has the potential of removing one vehicle in five from the fleet. Lean and green indeed. 0 by Danny Coughlan