Good prospects for lower price autos

Page 26

Page 27

If you've noticed an error in this article please click here to report it so we can fix it.

THE ARRIVAL of the fully automatic transmission as standard equipment rather than a rarely specified option has been predicted for many years. Predictions have a habit of going wrong, however, and that is the case here.

The automatic transmission, while being the norm in many passenger vehicle applications, is still looked at askance by the lorry operator. Is this situation changing and what are the likely technical developments in the future? Those are just two of the questions I put to Detroit Diesel Allison and Voith Engineering.

In Allison's experience, the development of automatic transmission market penetration is parallel between Europe and the USA but about 10 years behind. This is especially true in the field of municipal vehicles and local delivery.

The "specialist" refuse vehicle manufacturers, Dennis and Shelyoke and Drewry, are fitting automatic transmissions to about half of their production. However, with the non-specialist companies like Dodge and Seddon Atkinson, the percentage is less. There is always a first-cost penalty with an automatic gearbox and this varies from manufacturer to manufacturer with the most expensive being those who do not offer it as an on-line option.

Although the price penalty is usually over £2,000, manufacturers are now seeing the automatic gearbox as a means of selling the vehicle. This has been an interesting development of the recession in that chassis manufacturers have been so desperate to use factory capacity that they have been accepting "one-offs" and doing them inhouse.

Allison is seeing an increasing use of the long-haul specification vehicle for city delivery and this is one application where the fully automatic gearbox makes sense on a 32-38-tonner. Express Dairies, Unigate, and Rank Xerox are all currently evaluating Allison gearboxes both in brand new chassis and in conversions of existing vehicles.

The sales split of Allison applications makes interesting reading. In 1979, for example, the company supplied over 5,000 transmissions with the individual take-up being as follows: Local delivery 750 Medium vehicles 100 Long haul 60 Dumpers/mixers 300 Fire 300 Refuse/municipal 300 with the remainder being accounted for by the passenger market. Last year's figures (for 1981) were 40 per cent up on the sales shown above — and this refers to units not just market share.

The major technical de velopment in Allison's view is without doubt in the area of electronic control. The current hydraulic controls need to be calibrated specifically for the individual operation and this is getting out of hand both in terms of hardware numbers and in the limit of hydraulic control performance. Allison is developing a Universal Electronics Control (UEC) which is basically a minicomputer and this is claimed to suit any transmission with only minor tailoring.

Thus instead of having a vast range of hydraulic valve bodies, there will only be one plus the electronic control unit which can be programmed to give economy for a city bus or performance for an airfield crash tender. The UEC is also claimed to make the gearbox more reliable because of the greater accuracy in controlling shift points. Curre ntly Allison has got the tolerance band down to ±1Orpm compared with the ±50rpm wit the conventional hydraulics.

The principle of electroni control has been around for long time but the size and th cost of the componentry rathE weighed against it. In the la: few years, microchip technolog has reached the point where th technical potential can be uti ised at a sensible price.

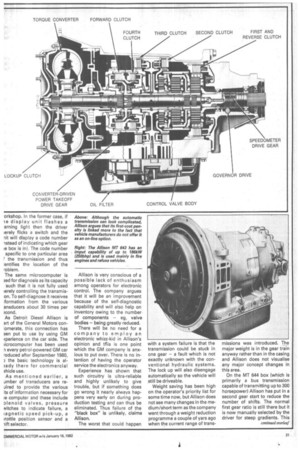

The Allison system feature the electronic control .unit in con junction with an electro-hy draulic valve body, a shif selector, a digital display unl and a variety of sensors includ ing one for speed and one fo throttle position.

Another major feature of till electronic system is its diagnos tic capability. It is possible ti have a display unit in the cab o as a plug-in device in thi

.orkshop. In the former case, if le display unit flashes a .arning light then the driver lerely flicks a switch and the nit will display a code number nstead of indicating which gear le box is in}. The code number specific to one particular area f the transmission and thus lentifies the location of the roblem.

The same microcomputer is sed for diagnosis as its capacity such that it is not fully used rerely controlling the transmison. To self-diagnose it receives 'formation from the various ansducers about 30 times per ?cond.

As Detroit Diesel Allison is art of the General Motors conlomerate, this connection has Ben put to use by using GM (perience on the car side. The iicrocomputer has been used n every petrol-powered GM car roduced after September 1980, ) the basic technology is alaady there for commercial ?hide use.

As mentioned earlier, a umber of transducers are reuired to provide the various its of information necessary for le computer and these include olenoid valves, pressure witches to indicate failure, a iagnetic speed pick-up, a irottle position sensor and a lift selector. Allison is very conscious of a possible lack of enthusiasm among operators for electronic control. The company argues that it will be an improvement because of the self-diagnostic capability and will also help on inventory owing to the number of components — eg, valve bodies — being greatly reduced.

There will be no need for a company to employ an electronic whizz-kid in Allison's opinion and t6is is one point which the GM company is anxious to put over. There is no intention of having the operator service the electronics anyway.

Experience has shown that such circuitry is ultra-reliable and highly unlikely to give trouble, but if something does go wrong it nearly always happens very early on during production testing and can thus be eliminated, Thus failure of the "black box" is unlikely, claims with a system failure is that the transmission could be stuck in one gear — a fault which is not exactly unknown with the conventional hydraulic systems. The lock up will also disengage automatically so the vehicle will still be driveable.

Weight saving has been high on the operator's priority list for some time now, but Allison does not see many changes in the medium/short term as the company went through a weight reduction programme a couple of yars ago when the current range of trans_ missions was introduced. The major weight is in the gear train anyway rather than in the casing and Allison does not visualise any major concept changes in this area.

On the MT 644 box (which is primarily a bus transmission capable of transmitting up to 300 horsepower) Allison has put in a second gear start to reduce the number of shifts. The normal first gear ratio is still there but it is now manually selected by the driver for steep gradients. This