[ From the Drawing 13021

Page 42

Page 43

If you've noticed an error in this article please click here to report it so we can fix it.

by Graham Montgomene by Graham Montgomene CM's Engineering Editor examines in detail the methods adopted by Foden and Rolls-Royce engineers to get the noise emissions of the 38-tonne-plated Foden down to 80dBA — as low as a saloon car's.

SINCE the start of the decade, work has been going on to reduce the noise emission of the heavy lorry. This culminated in the presentation last November of the final version of the Foden/ Rolls-Royce tractive unit which recorded 80dBA on a pass-by test 7.5m (24ft 7in) from the microphone — about the same level as that of a private car.

However, neither Fodens nor Rolls-Royce is likely to put the machine into production in its present form unless pressure from the legislature forces their hand — for reasons I will go into later. But at least the exercise has proved that the technology is available and that the industry is capable of defending itself against the charges of environmentalists.

Committee stage The quiet vehicle belies the well-worn criticisms of anything designed by a committee, as there were a number of parties involved. It started off back in 1970 when a noise group, including the Motor Industry Research Association, the Noise Advisory Council and the Transport and Road Research Laboratory got together to find what could be achieved in terms of noise reduction with a practicable vehicle.

As a result of this investigation, the Quiet Heavy Vehicle Project was initiated by TR RL in 1971 and was aimed at reducing external noise levels by around 10dBA. As this is a logarithmic scale, a 10dBA reduction halves the noise level_ With the average noise levels of 1971, this meant a target of 80dBA.

In the early stages Leyland. Fodens and Rolls-Royce were all involved but Leyland then dropped out because it -would have been out of phase with the commercial plans of the company." This would indicate that the decision to shelve the 500 engine was taken a lot earlier than many people think.

The first Foden guinea pig was a 44.7-tonne 6x2 tractive unit powered by a 260kW (350bhp) version of the RollsRoyce Eagle. At that time, this Foden was due to be superseded but, rather than wait for the later model, work on the exhaust and cooling systems was begun on the older version. The technology was then built into the new 4x2 Foden which was plated for 38 tonnes.

Power unit

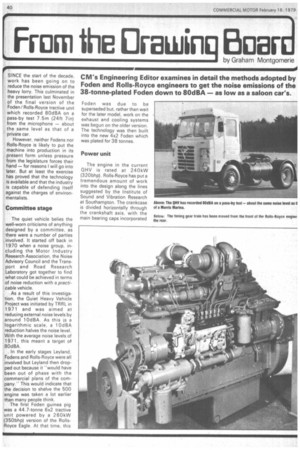

The engine in the current QHV is rated at 240kW (320bhp). Rolls-Royce has put a tremendous amount of work into the design along the lines suggested by the Institute of Sound and Vibration Research at Southampton. The crankcase is divided horizontally through the crankshaft axis, with the main bearing caps incorporated in the lower portion to increase the structural stiffness of the whole unit.

One interesting feature of the -redesignwas the re-siting of the timing gear train at the rear of the engine as the torsional activity is less near the flywheel The gears themselves are now helical in contrast to the usual Rolls-Royce practice of using straight-cut timing gears. This arrangement has worked well in reducing noise but it has raised the problem of what to do with the pto drive

Visually, one of the most obvious features of the Rolls engine is the cladding bolted to the external surfaces. Fodens and Rolls-Royce are reluctant to say just what the material is. but it appears to be a five-layer steel-neoprene sandwich which results in a very heavily damped panel.

The sump and rocker covers are isolated from the main crankcases structure by a moulded rubber gasket. According to Reg Lewis,

executive engineer-experimental at Fodens, the hardest part of the whole project was the design of the cooling system At the heart of the system is the fan which was designed by the National Engineering Laboratory, East Kilbricie, with the co-operation of Marston Radiators. It is of the mixed airflow type, that is, it combines centrifugal flow with axial flow and is hydraulically driven by a pump on the engine.

As the radiator — which was developed from a car design — and the fan take up a lot of room, the engine has been pushed back in the chassis by several inches. The radiator is in fact 16 per cent bigger than that required for the latest 216kW (290bhp) European Foden.

At the rear of the cab, some of the radiator air is exhausted via a slot in the glass-fibre engine cowl, while some is directed out above the rear axle. This cowl is fixed to the cab and thus tilts with it. In fact Fodens claim that in the fully-tilted condition it is possible to remove the engine without removing the cowl.

The silencer is a hefty-looking device designed by ISVR and the Cheswick and Wright Truck Silencer Division. It is mounted transversely in Pet Reg fashion and manages to incorporate two 1.8m (6 ft) long cylinders with a diameter of 254mm (1 Din) under the cab. There is no absorption material in the silencer — nor is there in Foden production silencers, come to that — as noise damping is achieved by tuned pipe lengths.

As you would expect, the cab itself has come in for some extensive insulation work. Soundabsorbent material has been fitted around the bulkheads and on the floor, while insulating foam has been pumped into the roof panels.

Successful

When tested using the standard pass-by test, the Foden recorded 80dBA, easily meeting the original target. Thus the technology is there. But how about its application to a production vehicle? For a start there is a weight penalty of around 250kg ( 5 cwt) The main culprits here are the cooling system, engine enclosures and the silencer. Rather surprisingly the engine is, in fact, lighter.

The real crunch comes when we start talking about cost. Current estimates put the price of a production version of the QHV at around 10 per cent higher than the standard vehicle. It is difficult to see operators accepting this cost penalty (and slightly more difficult servicing) without being compelled to by legislation.

But is such a vehicle necessary and where do we go from here? TRRL tests proved that the Foden/ Rolls Royce was as noisy (or as quiet) as a Morris Marina. Getting noise levels down to 80dBA is a fantastic achievement, but there the line will have to be drawn, as below this level tyre noise becomes predominant. And there is little that the tyre manufacturers can do about this until someone invents a "British Standard Road Surface