Boughton: back from the brink

Page 16

If you've noticed an error in this article please click here to report it so we can fix it.

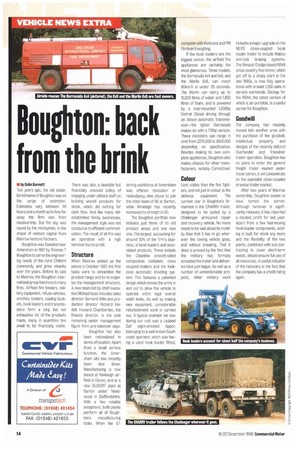

• by Colin Barnett Two years ago, the old established name of Boughton was on the verge of extinction. Estimates vary between 48 hours and a month as to how far away the firm was from receivership. But the day was saved by the moneyrnen, in the shape of venture capital from Manrow Venture Partners.

Boughton was founded near Amersharn in 1897 by Thomas T Boughton to serve the engineering needs of the rural Chiltern community and grew steadily over the years. Before its sale to Manrow. the Boughton International group had irons in many fires. Airfield fire tenders, military equipment, refuse vehicles, winches, tankers, loading buckets, hook loaders and transmissions form a long but not exhaustive iist of the products made, many in quantities too small to be financially viable. There was also a laudable but financially unsound policy of engaging under-utilised staff on building unsold products for stock, which did nothing for cash flow. And like many oldestablished family businesses, the management style was not conducive to efficient communication. The result of all this was an operation with a high turnover but no profit.

Sininire When Manrow picked up the pieces in October 1997, the first tasks were to streamline the product range and to re-organise the management structure. A new team led by chief executive Michael Isaac includes sales director Bernard Wills and production director Richard Kindel!. Howard Chamberlain, the finance director, is the sole remaining senior management figure from pre-takeover days.

Boughton has also

been rationalised in terms of location. Apart from a small service function, the Amersham site has recently been shut down. Manufacturing is now based at Winkleigh airfield in Devon, and at a new 35,000ft2 plant at Barton under Needwood in Staffordshire. With a few notable exceptions, both plants perform all of Bough

ton s manufacturing tasks. When the 67 strong workforce at Amersham was offered relocation or redundancy, nine chose to join the initial team of 56 at Barton, while Winkleigh has recently increased its strength to 80.

The Boughton portfolio now includes just three of its old product areas and one new one. The largest, accounting for around 50% of the firm's business, is hook loaders and associated products. These include the Cleanline smooth-sided compaction container, close coupled trailers and the Kwikcove automatic sheeting system. This features a patented design which moves the arms in and out to allow the vehicle to operate within legal overall width limits. As well as making new equipment, considerable refurbishment work is carried out A typical example we saw during our visit was a Leyland Oaf eight-wheeled tipper, belonging to a well-known South coast operator, which was having a used hook loader fitted, complete with Kwikcova and PM On-board weighing.

If the hook loaders are the biggest sector, the airfield fire appliances are certainly the most glamorous. Three models, the Barracuda 4x4 and 6x6, and the Marlin 6x6, can reach 80km/h in under 25 seconds. The Marlin can carry up to 15,000 litres of water and 1,800 litres of foam, and is powered by a rear-mounted 1,000hp Detroit Diesel driving through an Allison automatic transmission—the lighter Barracuda makes do with a 710hp version. These monsters can range Jn cost from £270,000 to £600,000 depending on specification. Besides making its own complete appliances, Boughton also makes chassis for other manufacturers, notably Carmichael,

Colour

Less visible than the fire fighters, and not just in colour, is the defence equipment. The current star in Boughton's firmament is the CRARRV trailer, designed to be pulled by a Challenger armoured repair and recovery vehicle. No more needs to be said about its mobility than that it has to go wherever the towing vehicle goes, and without brealung. That it does is proved by the fact that the military has formally accepted the trailer and deliveries have just begun. As well as a number of unmentionable projects, other military work includes a major upgrade on the MLRS close-coupled hook loader trailer to include Wabco anti lock braking systems. The Renault/Dodge-based RB44 cross-country five-toner, which got off to a shaky start in the late 1980s, is now fully operational with around 1,000 units in service worldwide. Backup for the RB44, the latest version of which is air-portable, is a useful earner for Boughton.

Goodwill

The company has recently moved into another area with the purchase of the goodwill, intellectual property and designs of the recently defunct Overlander and Transliner Tager operation. Boughton has no plans to enter the general freight trailer market under these names, it will concentrate on the specialist close-coupled drawbar trailer market.

After two years of Marrow ownership, Boughton seems to have turned the corner. Although turnover is significantly reduced, it has reported a modest profit for last year. Apart from a few fast-moving hook-loader components, nothing is built for stock any more and the flexibility of the two plants, combined with sub-contracting to cover short-term needs, should ensure full use of all resources. A useful indicator of the recovery is the fact that the company has a credit rating again.