Focus on

Page 38

Page 39

Page 40

If you've noticed an error in this article please click here to report it so we can fix it.

MEAT TRANSPORT

LAXITY in the transport and general handling of foodstuffs has always beeno matter of great concern to health authorities, yet no decisive steps have been taken to provide recognized standards of hygiene_ A high percentage of illness is directly attributable to food poisoning, and although it is not always possible to trace the source of the infection, the medical profession has repeatedly voiced the opinion that far too little attention is given to the protection of foodstuffs from contamination.

Meat, for example, is open to infection from the moment the animal is slaughtered and dressed, to the time the joint reaches the consumer. No matter how high the standard attained in killing and inspection, such efforts are negatived if the Means for transport be indifferent.

This was the opinion expressed at a food-handling conference recently held in Dundee. References were made at this conference to carcases being delivered to butchers' shops in open lorries covered in with dirty tarpaulins.

n4 When no enforced fixed standardS are laid down, meat transporters; in conjunction with bodybuilders, are left to evolve body types which are calculated to anticipate regulations which must, in due course, be formulated.

The Smithfield Show, at-Earls Court, revealed a number of interesting types of meat van, and in all cases the question of hygiene had undoubtedly

claimed first attention. An examinaCon of their individual features showed the general tendencies which are being followed, not only in the provision of hygienic transport, but in the simplification of loading and unloading carcases.

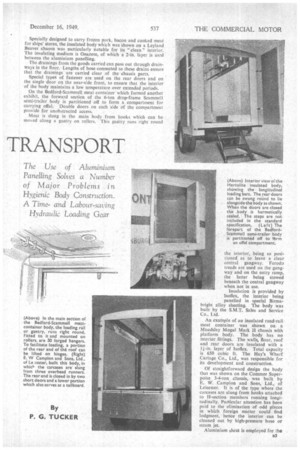

An. outstanding example was to be found in a body built by J. Ward and Sons. Ltd., Birnam Garage, Birnam Road, Holloway. London. N.4. This company is a meat haulier and, as one would expect, the design incorporated features introduced after years of experience with normal tyres of body. Apart from the .obviously hygienic character of the body, 'little manual effort is called foreitheiin loading Or unloading carcases.-. ThIs iseachieved by two hydraulic rams which raise and lower the loading bars.

Arranged on each side of the body, at the rear, is a vertically mounted hydraulic ram. The head of each ram has attached to it a length of channel material of the same section as the guide rails on which the loading beams run. There are two sets of guide rails, one mounted above the other.

If the van is being loaded, all the cross-beams, which arc provided with books, will be resting on the top set of rails. The control valve of the rams is

opened and both rams rise until their channel heads line up with the top guide rails. The rearmost loading beam is then rolled back until it rests on the ram heads, when the rams are retracted to bring the loading beam down to a convenient height.

After the carcases have been hooked on, the rams are again operated and allowed to rise until the heads reach the level of the lower guide rails. The porter then pushes the loaded beam forward, the rams are raised to the top guide rail, and the operation repeated.

Not only can the carcasses be manipulated with a minimum of physical effort, but the porter need,not enter the body either to load or unload. In the ordinary way, the rear end is closed-in by two swing doors, but the design also provides for the use of a " rollerblind" shutter which, when not covering the rear end, lies flat under the roof. To bring it into use, radiused corner pieces have to be swung into position to provide a track for the shutter.

• The body is 15 ft. long, 6 ft. 6 ins. wide, and 7 ft. high. It has a hardwood frame, panelled in light alloy. The hydraulic gear was devised and 'supplied by Equipment Repairs; Ltd., 19-20, The Viaduct., Alperton, Wembley. • Specially designed to carry frozen pork, bacon and cooked meat for ships' stores, the insulated body which was shown on a Leyland Beaver chassis was particularly notable for its "clean" interior. The insulating medium is Onazote, of which a 2-in, layer is used between the aluminium panelling.

The drainings from the goods carried can pass out through drainways in the floor. Lengths of hose connected to these drains ensure that the dratnings are carried clear of the chassis parts.

Special type § of fastener are used on the rear doors and on the single door on the near-side front, to ensure that the interior of the body maintains a low temperature over extended periods.

On the Bedford-Scammell meat container which formed another exhibit, the forward section of the 6-ton drop-frame Scammell semi-trailer body is partitioned off to form a compartment for carrying offal. Double doors on each side of the compartment provide for unobstructed access.

Meat is slung in the main body from hooks which can be moved along a gantry on rollers. This gantry runs right round

the interior, being so positioned as to leave a clear central gangway. Ferodo treads are used on the gangway and on the entry ramp, the latter being stowed beneath the central gangway when not in use.

Insulation is provided by Isoflex, the interior being panelled in special Birmabright alloy sheeting. The body was built by the S.M.T. Sates and Service Co.. Ltd.

An example of an insulated road-rail meat container was shown on a IS4audslay Mogul Mark 11 chassis with platform body. The body has no interior fittings. The walls, floor, roof and rear doors are insulated with a I 1-in. layer of Isollex. Total capacity is 650 cubic ft. The Hay's Wharf Cartage Co., Ltd., was responsible For its development and construction.

Of straightforward design the body that was shown on the Commer Superpoise 3-4-ton chassis, was built by E. W. Campion and Sons, Ltd., of Leicester. It is of the type where the carcases arc slung from hooks attached to H-section members running longitudinally. Particular attention has been paid to the elimination of odd places in which foreign matter could find lodgment, hence the interior can be cleaned out by high-pressure hose or steam jet.

Aluminium sheet is employed for the BS

body panels, and embossed light-alloy material is used to provide a non-slip floor.

The Herculite insulated meat-van' body, which was shown on a Fordson Thames 5-ton chassis, also has longitudinal loading bars beneath the roof. Its capacity is such that 60 medium

quarters can be carried. The steel loading bars are directly attached to the roof trusses.

Isoflex is used for insulating purposes, the roof, walls and doors being so treated. The rear doors are sealed with rubber. Roof ventilators, and rear steps housed beneath the floor can be supplied as extras. Interior dimensions of the body are, length, 13 ft. 8 ins., width 6 ft. 8 ins., and height 6 ft. 6 ins. It has a cubic capacity of 583 cubic ft. The complete vehicle weighs under 3 tons unladen.

Chester Coachworks, Ltd., of SaItney. recently completed a meat-carrying body for B. Buckley and Co., Ltd., Sale, Cheshire, a concern which has specialized in meat transport for the past 50 years. Based on a Bedford 3-4-ton chassis, the body incorporates racks for carrying carcases clear of the floor.

The interior is essentially hygienic,

THAT the tyres on a commercial

vehicle had the formidable and varied tasks of carrying the load, cushioning the vehicle and the goods or passengers it was carrying, and transmitting the driving, braking and steering forces, were points recalled by W. A.. Moots, Associnst.T., at the Institute of Transport on Monday. He was reading a paper prepared by Mr. H. Shankland, Minst.T., formerly of the Dunlop Rubber Co., Ltd.

It was for these reasons, said the speaker, that it took upwards of 30 years before tyres attained the standard of efficiency now achieved and expected. Up to 1899, solid rubber tyres on heavy lorries were a more or less untried proposition. E(ien in 1910 they, were listed, as alternative equipment to steel •tyres on some vehicles, and, of course, cost much more—about £250 per set.

Solid-tyre Mileages

Before the change to giant pneumatics, solid tyres on London General buses were giving greater mileages than 60,000. A major fault from which some solid tyres suffered was that of overheating, a condition so serious that the centre of the tyre often became liquid. This was followed by complete collapse.

When high-pressure giant pneumatic tyres were introduced into this country they were expensive. The speaker quoted the following prices:-32 in. by

6 in.' £32, compared with the present retail price of £11 12s. 6d.; 38 in. by

7 in., £60, as against £15 16s.; and 42 in. by 9 in., £110. compared with £31 3s. 6d.

It was not until June, 1928, when the permissible overall width of commercial vehicles was increased from 7 ft. 2 ins. to 7 ft. 6 ins., that Scotland Yard approved the use, in London, of giant pneumatics on double-deck buses. Some time after, the late Mr. George Shave, who was then chief engineer of the London General, rode blindfold on two buses, one fitted with solid tyres and the other with high-pressure giant pneumatics. He was unable to detect any difference in riding comfort.

The low-pressure or balloon tyre was eventually introduced, and this marked a further stage in the evolution and development of the commercial-vehicle tyre.

Suggestions were constantly being put forward for puncture-proof tubes and tyres, but up to the present these types had suffered from the disadvantages of being too heavy and too costly.

In showing some landmarks in the evolution of the pneumatic tyre, the speaker said that it was invented in 1845 by Mr. R. W. Thompson, a Scotsman. What seemed to be the first application of the giant pneumatic to commercial vehicles was in 1917, when an American operator ran an experimental service between Boston and Akron, a distance of 1,400 miles for the round trip.

Superiority of Rayon

So far as tyre construction was concerned, great improvements followed the cord method of building them up, as against the use of canvas. Rayon was now firmly established as the material for tyre foundations; not only was it suitable under high-temperature running conditions, but it combined strength with lightness. Although rayon was frequently referred to as artificial silk, this was not being panelled in 18-gauge galvanized sheeting. Two channels are formed in the floor to provide for drainage when the interior is washed down. A feature is to be found in the provision of roller shutters on each side of the body. The cubic capacity is 672 cubic ft.

What is to be learned from these body designs which represent the most modern tendencies in specialized vehicles for meat transport? In the first place aluminium is generally favoured for interior and exterior panelling, not merely because of its lightness, but because it is a poor radiator. For the latter reason it is, at present, ideally suited to the construction of insulated van bodies.

The hydraulic loading and unloading system as employed on the Ward body undoubtedly has great possibilities and "The Commercial Motor" foresees extensive developments based on this clever idea.

The main point, of course, is that the rates for meat haulage are such that the operator would not be justified in expending large sums of money on specialized types of vehicle, which explains the reason why such extensive use is made of " open lorries covered in with dirty tarpaulins."

true, as it was quite different from silk in chemical structure, -and had nOthing in common with silk, except, perhaps, in glossiness.

Whilst it was not being claimed, that the pneumatic tyre won the war, the tyre industry, as a whole, contributed largely to its successful issue.

The speaker then dealt at some length with the question of maintenance, in which he stressed the desirability of keeping tyres at correct pressures, as under-inflation was the main cause of tread wear and waste of power_

Dealing with the pneumatic tyre and. its sphere of application and usefulriess

in the field of agriculture, the speaker referred to the first use Of the wheel, which, he said, was about 5,000 years ago. It was only between 1930-1940 that the steel or wooden-tyred wheel had an alternative in the pneumatic-tyred wheel, which, for agricultural purposes, had a number of basic advantages.

Research and Development

For example, less power was needed to move loads over soft ground, equipment to which they were fitted had a longer life, and transport costs were reduced.

Large sums of money were still being spent on research and development to ensure that progress in the various fields of tyre construction might continue. There was now, said the speaker, close technical contact between commercial vehicle makers and tyre manufacturers, which resulted in benefit to the operator.

_Considerable progress had been made in the production of tyres which prevented the building-up of static electricity in the vehicle to which they were fitted. The rubber used was so compounded and processed as to be partially a conductor of electricity. The new steel tyres had casings constructed of plies of fine-gauge wire in place of the usual cotton or rayon cord.