WAYS AND MEANS.

Page 67

If you've noticed an error in this article please click here to report it so we can fix it.

Useful Contributions From Our Driver and Mechanic Readers.

What To Do When Packing Sentinel Glands.

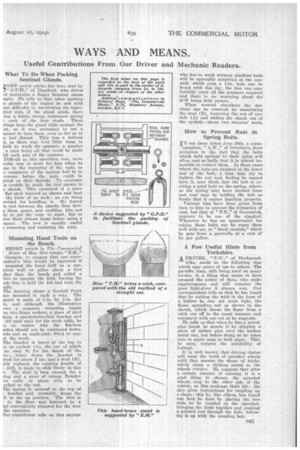

ONIE useful advice has been sent by 5" G.P.H.," of Deptford, who drives id maintains a Super Sentinel steam • agon. He tells us that when packing ie glands of the engine he met with )me difficulty in unscrewing the taperdied nuts of the gland studs, there :lug a fairly strong resistance spring

each of the four studs. These wings keep the gland tight against the its, so it was necessary to use a wilier to turn them. even so far as to le last thread. This was a tedious b, as there was very little room in hich to work the spanner, a quarter • a turn being all that could be made ith each grip of the spanner.

Difficult as this operation was, more ouble was in store for him when he tine to the replacing of the nuts, as e resistance of the springs had to be 'ercome before the nuts could he arted on their threads. To overcome is trouble he made the tool shown in e sketch. This consisted of a piece flat steel tapered as shown and bent the form of an arch; an eye being uvided for handling it. He forced is tool between the glands, thus forc g them apart, and enabling him not ly to get the nuts to start, but to rew them almost home before using a anner. The tool is equally useful r removing and replacing the nuts.

Mounting Hand Tools on the Bench.

FORT article in The Commercial" ' Motor of May 31st tempts "E.M.,"

Glasgow, to suggest that our corm,

ondent's idea would be improved if mounted the hand drill on a connient wall or pillar about a foot gher than the bench and added a vice to operate the feed,, leaving the ads 'free to hold the job and turn the ndle.

The drawing shows a Goodall Pratt ace mounted in such a way. The pport is made of 1-in, by i-in. fiat M, and although the illustration owe a separate mounting (made an two hinge sockets, a piece of steel

bing, a speedometer-link bracket and old tank cap) for the work table, he

?s no reason why the flat-iron acket should not be continued downirds and an angle-plate fitted to supet the work.

The bracket is bored at the top to fill :eyebolt (A), the eye of which an easy fit for the shank of the see ;. lower down the ..bracket is itted for about 3 ins. and a stud (B), deli replaces the existing _handle Of .? drill, is made to slide freely in this t. The stud is long enough for a ring and a piece of strOng Bowden ier cable or piano wire to be :ached to the end.

The Spring is secured to the top of ? bracket and, normally, • keeps the II in the up position. The wire is . to the floor and fastened to a lal conveniently situated for the foot the operator.

Our contributor tells us that anyone who has to work without Machine tools will be •agreeably surprised at the ease with which even a fin. hole can be bored with this rig; the foet can comfortably exert all the pressure required and there is no worrying about the drill being held square.

When wanted elsewherethe machine can be removed by unscrewing the stud (B), loosening the nut of eyebolt (A) and sliding the shank out of the eyebolt—about two minutes' work.

How to Prevent Rust in Spring Bolts.

IN our issue dated June 28th, a corre spondent, " A.W.." of Dewsbury, drew attention to the fact that the bolts which hold springs to their axles will often rust so badly that it is almost impossible to remove them. In those eases where the nuts are situated at the lower end of the bolt, a man may try to tighten the nut and, finding he cannot turn it, may think, that the bolt is exerting a good hold on the spring, whereas the spring' may have worked loose and rust may be holding the bolt so firmly that it cannot function properly.

Various tips have been given from time to time to prevent the formation of rust, but that of "F.S.," of Greenwich, appears to be one of the simplest. Whenever he has an opportunity for taking these bolts out he coats them well with tar. or "black varnish," which he gets from a gasworks at a cost of Is. per gallon.

A Few -Useful Hints from Yorkshire.

'A DRIVER, "T.W.," of Heckmondwike, sends us the following tips

which may prove of use to others. The paraffin lamp, still being used on many lorries, is a thing that seems to have escaped the notice of those who make improvements and still remains the poor light-giver it always was. Our correspondent tells us that he has found that by cutting the wick in the form of a hollow he can get more light, the flame spreading out as shown in the sketch, which shows the flame from a wick cut OE in the usual manner, and compared with one cut as he suggests.

He tells us that when he has a petrolpipe break he mends it by slipping a piece of rubber pipe over the broken metal one, but before doing so he takes care to apply soap to both pipes. This. he says, reduces the possibility of leakage.

It is well known that driving chains will wear the teeth of sprocket wheels until they assume the shape of hooks, which cause a clicking sound as the wheels revolve. He suggests that after a certain amount of running it is a good thing to change the sprocket wheels over to the other side of the vehicle, as this prolongs their life. He also gives instructions for coupling up a chain; this he, .like others, has found can best be done by placing the two Pnds to be coupled on the sprocket, bringing the links together and pushing a pointed tool through the hole, following it up with the coupling bolt.