HINTS ON MAINTENANCE.

Page 66

If you've noticed an error in this article please click here to report it so we can fix it.

End-play in A.E.C. Rear Wheels. An Improvement to the 15-ter Fiat. Dealing With a Chevrolet Clutch Spring.

Taking up End-play in A.E.C. Rear Wheels.

MHE rear-wheel hubs on the standard 4-ton A.E.C. J_ .chassis give little or no trouble when correctly erected, but end-play is certain to develop after long usage, and it is obvious from examination of certain vehicles that the method of taking up this play is little understood.

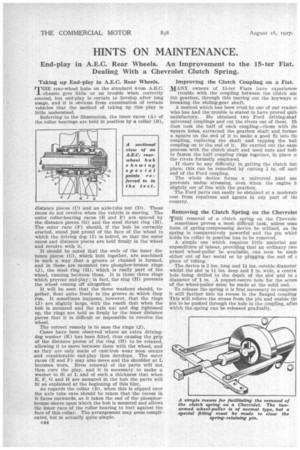

Referring to the illustration, the inner races (A) of the roller bearings are held in position by a collar (B), distance pieces (C) and an axle-tube nut (D). These races do not revolve when the vehicle is moving. The outer roller-bearing races (E and F) are spaced by the distance pieces (0) and the steel thrust ring (H). The outer race (F) should, if the hub be correctly erected, stand just proud of the face of the wheel to which the driving dog (I) is bolted, so that the outer races and distance pieces are held firmly in the wheel and revolve with it.

It should be noted that the ends of the inner distance pieces (C), which butt together, are machined in such a way that a groove or channel is formed, and in these are mounted two phosphor-bronze rings (J), the steel ring (H), which is really part of the wheel, running between them. It is these three rings which prevent end-play; in fact, the ring (H) prevents the wheel coming off altogether.

It will be seen that the three washers should, together, float quite freely in the groove in which they kun. It sometimes happens, however, that the rings (r) are slightly large, with the result that when the hub is mounted and the axle nut and dog tightened up, the rings are held so firmly by the inner distance pieces that it is difficult or impossible to revolve the wheel.

The correct remedy is to ease the rings (J).

Cases have been observed where an extra drivingdog washer (K) has been fitted, thus causing the grip of the distance pieCes of the ring (H) to be relaxed, allowing it to move between them with the wheel, and as they are only made of east-iron wear soon occurs and considerable end-play then develops. The outer races (E and F) may also move and the shoulder at L' becomes worn. Even renewal of the parts will not then cure the play, anti it is necessary to make a washer to fit at L and of such a thickness that when E, 10, 0 and H are mounted in the hub the parts will fit as explained at the beginning of this hint.

As regards the collar (B), when this is slipped over the axle tube care should be taken that the recess in it faces outwards, as it takes the end of the phosphorbronze sleeve upon which the hub is mounted and allows the inner race of the roller bearing to butt against the face of this collar. The arrangement may seem complicated, but is actually quite simple.

Improving the Clutch Coupling on a Fiat.

MANY owners of 15-ter Fiats have experience( trouble with the coupling between the clutch an thb gearbox, through this tearing out the keyways oi breaking the sliding-gear shaft.

A method which has been tried by one of our reader who has had the trouble is stated to have proved quih satisfactory. He obtained two Ford driving-shaf universal Couplings and cut the rivets out of them. HI then took the half of each coupling—those with tin square holes; extracted the gearbox shaft and .forme( a square on the end of it to make a good fit into tin coupling, replacing the shaft and tapping the hall coupling on to the end of it. He carried out the sant( process with the clutch .shaft and used nuts and both to fasten the half coupling rings together, in place .0: the rivets formerly employed.

If there be any difficulty in getting the clutch int( place, this can be remedied IV cut hug 1 in. off eack end of the Ford coupling.

The whole device forms a universal joint an prevents undue stressing, even when the engine h slightly out of line with the gearbox.

The Ford parts can easily be obtained at a moderat( cast from repairers and agents in any part of tin country.

Removing the Clutch Spring on the Chevrolet

THE removal of a clutch spring on the Chevrole sometimes proves a most difficult task, unless sottu form of spring-compressing device be utilized, as tin spring is comparatively powerful and the pin whicl bolds its collar in position has to be removed.

A simple one which requires little material ark expenditure of labour, providing that an ordinary two armed wheel-puller be available, can soon be mad( either out of bar metal or by plugging the end of r piece of tubing.

The device is 2 ins, long and 11 ins. outside diameter whilst the slot is 1 ins, deep and g in. wide, a centre: hole being drilled to the depth of the, slot and to o diameter of I in. A poppet-centre hole for the serem of the wheel-puller must be made at the solid end. To release the spring it is first necessary to compres It still farther into its recess in the flanged coupling This will relieve the stress from the pin and enable thE pin to be pushed through the hole in the coupling, after which the spring can be released gradually.