THE LATEST DENNIS GULLY EMPTIER.

Page 61

If you've noticed an error in this article please click here to report it so we can fix it.

An Appliance Which Enables a Branch of Municipal Work to be Performed Efficiently and Economically.

ALL progressive municipal authorities readily acknowledge the importmice of the motor gully emptier, be it petrol or steam driven, as a useful adjunct to their usual mechanical equip ment. They recognise that the oldfashioned methods of removing slop from a gully and of resealing it were not only inefficient but often insanitary, and that the modern motor appliance enables the work to be carried out not only with greater expedition but with the certainty that the air is not being unduly polluted. Most of the. prominent commercial-vehicle makers include in their range of municipal appliances gully emptiers of one or more sizes, and one of the types that has won considerable recognition in municipal circles is that marketed by Dennis Bros., Ltd., of Guildford.

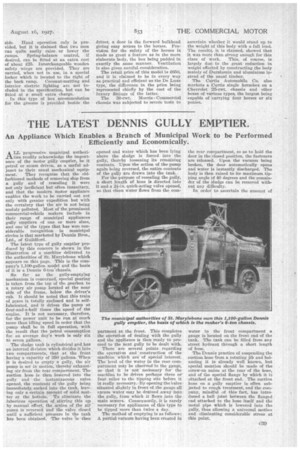

The latest type of gully emptier produced by this concern is shown in the illustration of a machine delivered to the authorities of St. Marylebone which appears on this page. This is the company's 1,100-gallon model and the basis of it is a Dennis 6-ton 'chassis.

So far as the gully-emptying mechanism is concerned special gearing is taken from the top of the gearbox to a rotary air pump located at the near side of the frame, below the driver's cab. it should be noted that this train of gears is totally enclosed and is selflubricated, and it drives the pump at four-and-a-half times the speed of the engine. It is not necessary, therefore, for the power unit to be run at much more than idling speed in order that the pump • shall be in full operation, 'with the result that the petrol consumption for an average day's work is only six to seven gallons.

The sludge tank is cylindrical and has an internal division which divides it into two compartments, that at the front • having a capacity of 350 gallons. When it is desired to empty a gully, the air pump is set in motion, thereby exhausting air from the rear compartment. The suction hose is then lowered into the gully and the. instantaneous valve opened, the contents' of the gully being immediately, sucked into the tank, leaving only a -certain amount of solid mat-.

• ter at the botioin. To eliminate the laborious operation of stirring this up

• by manual effort, the action of the air pump is reversed and the valve closed until a sufficient pressure in the tank • has been obtained. •Thevalve isthen

opened and water which has been lying above the sludge is forced into the gully, thereby loosening its remaining contents. Upon the action of the pump again being reversed, the entire contents of the gully are drawn into the tank.

For the purpose of resealing the gully, a short length of hose is directed into it and a 2i-in. quick-acting valve opened, so that clean water flows from the corn partment at the front. This completes the operation of dealing with the gully and the appliance is then ready to proceed to the next gully to be dealt with.

There are several points regarding the operation and :construction of the machine' which are of • special' interest. The level of the water in the rear cornpartnient may be observed in the gauge, sothat it is not necessary for ale machine to be driven perhaps three or font.. miles' • to the tipping site before it is really necessary., By opening the 'valve' situated slightly in front of the gauge all' excess water may be drained away into the gully, from which it flows into the main sewers. Censeq neatly, it is rarely necessary for appliances Of this type to be tipped more than twice a day.

The method of emptying is as follows: A pai-tial vacuum having been created in

the rear compartment, so as to hold the door in the closed position, the fasteners are released. Upon the vacuum being broken, the door automatically opens and water is instantly discharged. The body is then raised to it maximum tipping angle of 40 degrees and the remainder of the sludge can be removed without any difficulty.

In order to ascertain the amount of water in the front compartment a gauge is located on the front end of the tank. The tank can be filled from any street hydrant through a short length of hose.

The Dennis practice of suspending the suction hose from a rotating jib and balancing it is already well known, but special mention should be made of the screw-on union at the rear of the hose, and of the special flange by which it is attached at the front end. The suction hose on a gully emptier is often subjected to rough treatment, and the company, mindful of this fact, has intrdduced a ball joint between the flanged end attached to the hose itself and the metal pipe which is lowered into the gully, thus allowing a universal motion and eliminating considerable stress at this point.