Where drawbars score

Page 46

Page 47

If you've noticed an error in this article please click here to report it so we can fix it.

Some operators hanker for an all-British fleet for carrying all-British goods. Graham Montgomerie meets one in a Gardner engines enthusiast and Leicester pie maker

THE INCREASED weight regulations refer to articulated vehicles only — drawbar combinations are specifically excluded. However, there is still a very definite market for drawbars for certain types of operation. For high cube loads where weight is not at a premium, the sheer size of available platform length makes the drawbar a useful proposition.

One company which is starting to run some drawbars is R. F. Brookes of Leicester, manufacturer of pies and pasties. In this company's particular application, the drawbar can carry 45 trolleys compared with the maximum of 36 which can be accommodated in a standard 40ft fridge van.

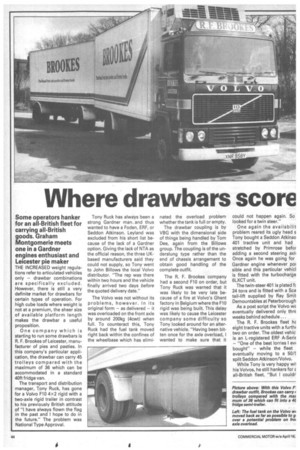

The transport and distribution manager, Tony Ruck, has gone for a Volvo F10 4x2 rigid with a two-axle rigid trailer in contrast to his previously British attitude of "I have always flown the flag in the past and I hope to do in the future." The problem was National Type Approval. Tony Ruck has always been a strong Gardner man_ and thus wanted to have a Foden, ERF, or Seddon Atkinson. Leyland was excluded from his short list because of the lack of a Gardner option. Giving the lack of NTA as the official reason, the three UKbased manufacturers said they could not supply, so Tony went to John Billows the local Volvo distributor. "The rep was there within two hours and the vehicle finally arrived two days before the quoted delivery date."

The Volvo was not without its problems, however. In its original form — as delivered — it was overloaded on the front axle by around 200kg (4cwt) when full. To counteract this, Tony Ruck had the fuel tank moved right back within the confines of the wheelbase which has elimi nated the overload problem whether the tank is full or empty.

The drawbar coupling is by VBG with the dimensional side of things being handled by Tom Dee, again from the Billows group. The coupling is of the underslung type rather than the end of chassis arrangement to obtain good handling of the complete outfit.

The R. F. Brookes company had a second F10 on order, but Tony Ruck was warned that it was likely to be very late because of a fire at Volvo's Ghent factory in Belgium where the F10 rigid was being built. This delay was likely to cause the Leicester company some difficulty so Tony looked around for an alternative vehicle. "Having been bitten once for the axle overload, I wanted to make sure that it could not happen again. So looked for a twin steer."

One again the availabilit problem reared its ugly head s Tony bought a Seddon Atkinso 401 tractive unit and had stretched by Primrose befor adding a second steering axli Once again he was going for Gardner engine whenever pol sible and this particular vehicl is fitted with the turbocharge 6LXCT unit.

The twin-steer 401 is plated fc 24 toils and is fitted with a Sca tail-lift supplied by Ray Smit Demountables at Peterborough As a post script the Volvo WE eventually delivered only thre weeks behind schedule ...

The R. F. Brookes fleet hz eight tractive units with a furth( two on order. The oldest vehic is an L-registered ERF A-SeriE — "One of the best lorries I ev( bought" — while the fleet eventually moving to a 50/E split Seddon Atkinson/Volvo.

While Tony is very happy wil his Volvos, he still hankers for E all-British fleet. "But I couldr get what I wanted. What would jou have done in my place?"

All but one of the Seddon At Because of the power of the 290L, Mr Ruck had a Fidus road speed limiter fitted to the Sed don Atkinson with a similar device being fitted to the Chinese Six which has a geared top speed of well over 70mph in top. Not entirely satisfied with the -..tonstruction of the Fidus, Tony suck is going for Smiths speed imiters on his new Volvo. The R. F. Brookes fleet has 14 drivers, all Class One, with each driver keeping to his own vehicle. Experience has shown :hat this is the best way of keep ng the requipment in good 3rder and keeping the insurance Premiums down, Tony Ruck said: "We've been lucky lately in that we are keeping our drivers. They've settled down and we've low got some good men." Food producers have to be extremely conscious about hy giene. This refers not only to ooking after the load but also to providing a good public image. Because of the latter ("Those lor les are our shop window") Tony Forbids any stickers, Michelin -nen, etc, on his fleet. He is also :otally opposed to CB radio. He Feels that drivers should be conentrating on the job in hand, lamely getting the load from A :o B safely and on time. The latest bodies to be fitted 3n the Volvos and Seddon Atkin sons are from Bostock and Barsby Ltd of Barwell in Leices.ershire. The company came into ....ontact with the R. F. Brookes 3peration through the local Seddon Atkinson agent for some 3ainting work. The early bodies supplied con3isted of an aluminium shell with a sprayed on lining of poly urethane. Later bodies have Peen lined with aluminium on :op because of the knocking 3bout received during the loadng and unloading of the pallets. Ns Ken Barsby, a director of Bos.ock and Barsby, explained: 'Aluminium will still get dented, nit it won't pierce and it won't et the water in." The bodies are all fitted with Petter fridges to keep the load at its recommended temperature of 3/4°C (38/40°F) with the rigids using the horizontal LOC2 and the trailers using the vertical DKL type. At the Magna Road premises of R. F. Brookes there is a large deep-freeze store which can handle up to 100 tons of raw materials — and this too comes within the jurisdiction of Tony Ruck. Bostock and Barsby also built a little (about 10ft) box-bodied two-axle trailer to go behind a forklift truck. This has a payload of 1,520kg (30cwt) and is for use only within the premises of R. F. Brookes. My visit to Magna Road took place on the day before Good Friday, a less than satisfactory timing so far as Tony Ruck was concerned. The whole fleet is cleaned over every weekend so our photographs show the vehicles and trailers in just about their worst possible condition thanks to the recent bad weather! This exterior cleaning is in addition to the usual daily steam cleaning of the interior. The fleet rarely operates at the weekend although it is always in action at Bank Holidays stocking up the supermarkets for opening the next day. Tony Ruck is proud of his fleet but acknowledges the help he receives from all his suppliers including Bostock and Barsby, the Billows Group, Petters and Ray Smith.Tags