Engineer's noteboolc

Page 55

Page 56

Page 57

If you've noticed an error in this article please click here to report it so we can fix it.

In spite of their obvious advantages and recent improvements in design, anti-lock braking systems have been slow to catch on among operators. In the first instalment of a two-part article, Tim Blakemore traces the development of these potential life savers and looks at some of the problems which have been encountered

ANY VISITOR to the CM sponsored Lorry Driver of the Year finsls at Cranfield last weekend would surely have been impressed by the demonstration of the effectiveness of anti-lock braking. This was mounted

jointly by Clayton Dewandre and Mercedes-Benz.

When an unladen articulated vehicle is braked very hard from 50 mph on a very slippery surface and it comes to rest with no drama, under the driver's full control and in a short distance, it is obvious that there is something special about its braking system. Anyone who has driven or been a passenger in a mod ern anti-lock demonstration vehicle in these conditions will be even more impressed.

At the weekend demonstration you could have hit the brake pedal as hard as you wanted. Still the vehicle would have stopped with no hint of the pulse-quickening twitching out of line which even the most skilful driver would be hard put to avoid in a conventional vehicle.

Manufacturers of anti-lock brake equipment know how convincing these 'hands-on' demonstrations can be, even to notoriously sceptical haulage operators, which is why they go to so much trouble to arrange them. Yet, the number of operators so far who pay the premium for anti-lock and specify it when ordering new vehicles remains surprisingly small. It has been estimated that no more than 10,000 commercial vehicle anti-lock systems of all types are manufactured each year, and that is a worldwide figure. Though every operator needs to be cost conscious nowadays, surely it cannot be only the price which deters so many from equipping their vehicles with devices which offer at least the potential of improved safety.

Despite what many anti-lorry campaigners would have you believe, the majority of operators do care a good deal about the safety of their drivers and other road users. But it seems that anti-lock braking is destined to become yet another measure aimed at improving road safety which is only widely adopted when legislation forces

it.

The likelihood is that Europe will lead on the introduction of such legislation, and sooner rather than later. That is why there has been so much activity lately among the leading systems manufacturers as they jostle for pole position in pre paration for the day when the legislative flag comes down.

Performance specifications for anti-lock equipment vehicles have already been drafted by the United Nations Economic Commission for Europe and they are contained in the now quite well known Appendix 13 to ECE Brake Regulation No 13. But a number of questions about the timing and detail of enforcing EEC legislation, still remain unanswered.

Probably one of the reasons for greater than usual caution from the European legislators on this subject and, indeed, a likely reason for the lack of enthusiasm to date from many European fleet operators is the unhappy experience in America with commercial vehicle antilock legislation.

From March 1975 to April 1978 there was an indirect mandatory requirement in the USA' for anti-lock to be fitted to air braked heavy vehicles.

To describe this legislation as unpopular and unsuccessful would be a gross understatement. The essential problem was that the systems were unreliable and one particular defect often quoted was that the operation of citizens band radios would seriously affect the brakes' electronic control units. 3ut the European anti-lock systems of today are very different from those of eight or nine years ago in the USA.

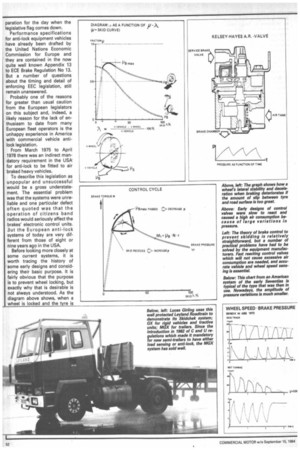

Before looking more closely at some current systems, it is worth tracing the history of some early designs and considering their basic purpose. It is fairly obvious that the purpose is to prevent wheel locking, but exactly why that is desirable is not always understood. As the diagram above shows, when a wheel is locked and the t re is

skidding along the road surface its resistance to lateral movement, or lateral force coefficient, (expressed as jtS in the diagram) is virtually zero. This coefficient reaches its peak (in other words its resistance to a side force is at its greatest) when the wheel is in a free rolling condition. When the drive-axle wheels of a tractive unit begin to move sideways the vehicle is moving into a jack-knife condition and, clearly, when any vehicle's steered wheels lose their lateral stability the driver will not be able to steer.

Again, as shown in the diagram, the friction between tyre and road surface in the direction of rotation of the wheel behaves differently as the degree of slip increases and the braking force coefficient usually reaches its maximum at about 15 per cent wheel slip, that is when the peripheral speed of the wheel is some 15 per cent slower than the linear speed of the vehicle.

It is generally agreed that steering and lateral stability remain adequate between about 10 and 30 per cent wheel slip, which is the area in which the shortest stopping distances will be achieved. Therefore, anti-lock systems are designed to modulate braking force, and thus wheel slip, to stay within this band.

Development work on various systems which would achieve this began a long time ago. Scania's engineers, for example, have even unearthed a patent application from the mid 1920's.

Mechanically regulated systems have achieved a degree of success on railway vehicles, but it is clear that the different problems of automotive applications would always prevent these being used here.

It was towards the end of the 1960's that commercial vehicle and car anti-skid system development work really began to gather pace and it is no mere coincidence that this was at the same time as a boom in the electronics industry, with the introduction of suitable transistors and integrated circuits.

The speed of reaction demanded by an anti-lock brake system is measured in milliseconds and can only be practically achieved electronically. Though systems for cars have to operate at higher vehicle speeds there are more special problems associated with commercial vehicle anti-lock. These include large weight variations between axles and between laden and unladen conditions, a wide variety of wheelbases and body types, greater weight transfer during braking and greater inertia of wheels and running gear.

A basic requirement for any system is the ability to detect when a wheel is beginning to lock and then for it to react quickly and reduce braking pressure. As the percentage slip of the wheel reduces, the system must once again react quickly to restore braking pressure or the result will be an increase in stopping distance.

One of the fundamental failings of some early anti-lock systems was their inability to react quickly enough to changes in wheel slip.

Some early systems depended solely on a signal relating to the wheel's acceleration or retardation (skid sensing) as a control parameter, but it soon became evident that accurate vehicle speed sensing was also necessary if the system was not to be deceived into allowing premature wheel lock.

The low speed reaction of the air brake valves first used to modulate braking pressure was another obstacle which had to be overcome before today's level of sophistication of antilock systems could be reached.

A wheel that is close to locking can begin to lock and become unstable in as little as 30 milliseconds. Early single solenoid control valves had an onoff function and their reaction time was no better than 50 milliseconds. The fact that some modern valves are able to react in about 10 milliseconds illustrates how far the system manufacturers have progressed.

The second part of this feature in next week's issue will look more closely at the way some modern control valves work, and at the Wabco and Lucas Girling Skidchek systems in particular.