Important Factors in

Page 54

Page 55

If you've noticed an error in this article please click here to report it so we can fix it.

SEAT CONSTRUCTION

Our Bodybuilding Expert Gives his Views on Seat Building and Draws Attention to Features of Design

ADOUBLE crosswise seat is not less than 2 ft. 8 ins, long and 1 ft. 3 ins, wide. The seat back slopes 5 ins. or 6 ins, from the vertical, so that, added to the width of the cushion, the seat occupies about 1 ft. 8 ins. Of the length of the vehicle.

This size of seat should not be exceeded unless the spacing of the seats, measured from back to back, exceeds 2 ft. 3 ins., because wider cushions and more comfortable backrests, if introduced without any increase of spacing, reduce unduly the width of the cross-gangways.

In front the top of the cushion averages 1 ft. 5 ins, from the floor and slopes downwards 2 ins, towards the back. The overall height of the seat is, nowadays, seldom less than 2 ft. 9 ins, and coach seats sometimes exceed 3 ft.

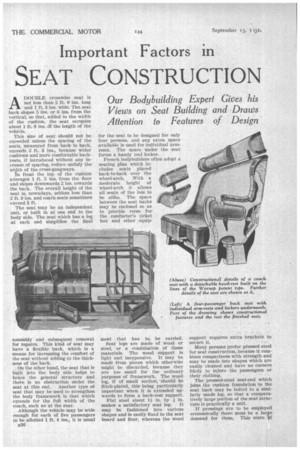

The seat may be an independent unit, or built in at one end to the body side. The seat which has a leg at each end simplifies the final assembly and subsequent removal for repairs. This kind of seat may have a flexible back, which is a means for increasing the comfort of the seat without adding to the thickness of the back.

Mn the other hand, the seat that is built into the body side helps to brace the general structure and there is no obstruction under the seat at this end. Another type of seat that may be used to strengthen the body framework is that which extends for the full width of the coach, such as at the rear.

Although the vehicle may be wide enough for each of five passengers to be allotted 1 ft. 4 ins., it is usual B36 for the seat to be designed for only four persons, and any extra space available is used for individual armrests. The space under the seat forms a handy tool locker.

French bodybuilders often adopt a seating plan which includes seats placed back-to-back over the wheel-arch. With a moderate height of wheel-arch it allows all seats of the bus to be alike. The space between the seat backs may be enclosed so as to provide room . for the conductor's ticket box and other equip ment that has to. be carried.

Seat legs are made of wood or steel, or a combination of these materials. The wood support is light and inexpensive. It may be made from pieces which otherwise might be discarded, because they are too small for the ordinary purposes of framework. The wood leg, if of small section, should be flitch-plated, this being particularly important when it is extended upwards to form a back-rest support.

Flat steel about 14 in. by in. makes a satisfactory seat leg. It may be fashioned into various shapes and is easily fixed to the seat board and floor, whereas the wood support requires extra brackets to secure it.

Many persons prefer pressed steel for seat construction, because it combines compactness with strength and may be made into shapes which are easily cleaned and have no corners likely to injure the passengers or their clothing.

The pressed-steel seat-end which joins the cushion foundation to the seat back may be bolted to a similarly made leg, so that a comparatively large portion of the seat structure is practically a unit.

If pressings are to be employed economically there must be a large demand for them. This state Vf

affairs should exist, because even if each bodybuildeewishes to vary the detail design of his products, he may still do so by using stampings made in one or two varieties.

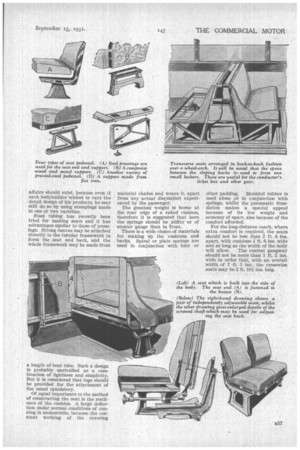

Steel tubing has recently been tried for making seats and it has advantages siptilar to those of pressings. Strong canvas may be attp.ched directly to the tubular framework to form the seat and back, and the whole framework may be made from

a length of bent tube. Such a design is probably unrivalled as a combination of lightness and simplicity. But it is considered that lugs should be provided for the attachment of the usual upholstery.

Of equal importance to the method of constructing the seat is the resilience of the cushion. A large deflection under normal conditions of running is undesirable, because the constant working of the covering

material chafes and wears it, apart from any actual discomfort experienced by the passenger.

The greatest weight is borne at the rear edge of a raked cushion, therefore it is suggested that here the springs should be stiffer or of stouter gauge than in front. There is a wide choice of materials for making up the cushions and backs. Spiral or plate springs are used in conjunction with hair or other padding. Moulded rubber is used alone ot in conjunction with springs, whilst the pneumatic foundation makes a special appeal because of its low weight and economy of space, also because of the comfort afforded.

For the long-distance coach, where extra comfort is required, the seats should not be less than 2 ft. 6 ins. apart, with cushions 1. ft. 6 ins, wide and as long as the width of the body will allow. • The central gangway should not be more than 1 ft. 2 ins. wide in order that, with an overall width of 7 ft. 5 ins., the crosswise seats may be 2 ft. 101 ins. long.