A One-ton Trailer for All Climates.

Page 19

If you've noticed an error in this article please click here to report it so we can fix it.

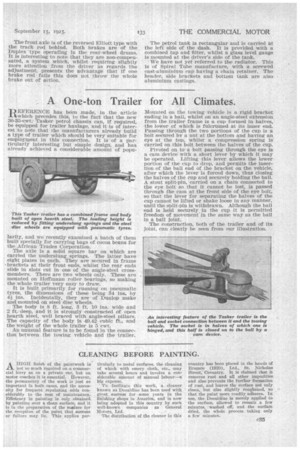

11,11 EFERENCE has Wen .made, in the article IA/which precedes, this, to the fact that the new 30-35-cwt.' Tasker petrol Chassis can, if required, be equipped for trailer haulage, and it is of interest to note that the manufacturers already build a type of trailer which should be very'suitable for employment in this connection. It is of a particularly interesting but simple design; and has already achieved a considerable amount of popu larity, and we recently examined a batch of them built specially for carrying bags of cocoa beans for the African Trades Corporation. The axle is a solid square bar on which are carried the underslung springs. The latter have eight plates in each. They are secured in frame brackets at their front ends, whilst the rear ends slide in slots cut in one of the angle-steel crossmembers. There are two wheels only. These are mounted on Hoffmann roller bearings, so making the .whole trailer very easy to draw.

. It is built primarily for running on pneumatic tyres, the dimensions of these being 34 ins. by 4/ ins. Incidentally, they are of Dunlop make and mounted on steel disc wheels.

The body is 8 ft. long, 3 ft 10 ins, wide and 2 ft.-deep, and it is strongly constructed of open hearth Steel, well braced with angle-steel pillars. The capacity of the body is 49.42 cubic ft., and the weight of the whole trailer is 5 'cwt.

" An unusual feature is to be found in the connection between the towing vehicle and the trailer.

Mounted on the towing vehicle is a rigid bracket ending in a ball, whilst on an angle-steel extension from the trailer frame is a cup formed in halves, the lower of which is fulcrumed at its inner end. Passing through the two portions of the cup is a bolt secured bv a nut at the bottom and having an eye at the top, whilst a compression spring is carried on this bolt between the halves of the cup.

Pivoted on to a bolt passing through the eye is a cam device with a short lever by which it may be operated. Lifting this lever allows the lower portion of the cup to drop, and permits the insertion of the ball end of the bracket on the vehicle, after which the lever is forced down, thus closing the halves of the cup and securely holding the ball. A stout split-pin, carried on a chain connected to the eye bolt so that it cannot be lost, is passed through the cam at the front side of the eye bolt; so that the lever for separating the halves of the cup cannot be lifted or shake loose in any manner, until the split-pin is withdrawn. Although the ball end is held securely, in the cup it is permitted freedom of movement in the same way as the ball in a ball joint.

The construction, both of the trailer and of its joint, can clearly be seen from our illustration.