MAN'S SLICK SHIFTER

Page 56

Page 57

Page 58

Page 59

If you've noticed an error in this article please click here to report it so we can fix it.

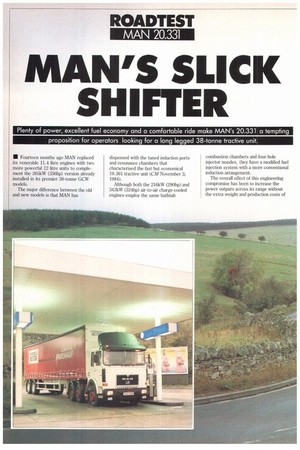

Plenty of power, excellent fuel economy and a comfortable ride make MAN's 20.331 a tempting proposition for operators looking for a long legged 38-tonne tractive unit.

• Fourteen months ago MAN replaced its venerable 11.4 litre engines with two more powerful 12 litre units to complement the 265kW (356hp) version already installed in its premier 38-tonne GCW models.

The major difference between the old and new models is that MAN has

dispensed with the tuned induction ports and resonance chambers that characterised the fast but economical 19.361 tractive unit (CM November 3, 1984).

Although both the 216kW (290hp) and 342kW (324hp) air-to-air charge-cooled engines employ the same bathtub

combustion chambers and four-hole injector nozzles, they have a modified fuel injection system with a more conventional induction arrangement.

The overall effect of this engineering compromise has been to increase the power outputs across its range without the extra weight and production costs of

tuned induction resonance. Torque output is unchanged but in the sleeper-cabbed 20.331 FM'S the 243kW gave an excellent all-round performance.

MAN's 243kW D2866FLZ engine produces in excess of 1,300Nm (959 lb ft) between 1,100 and 1,700rpm in the form of a long plateau.

Conversely its specific fuel consumption curve remains below 204g/kW-h across this rev range, dropping to 200g/kW-h between 1,300 and 1,650rpm. Tailored to the standard Eaton TS011612 Twin Splitter gearbox and the fastest 4.04:1 final drive option it holds the 80 and 96km/h speed limits in 4th high (top) gear at 1,400 and 1,650rpm respectively.

• FUEL ECONOMY

This gives it excellent cruising economy on dual-carriageways and motorway as shown by the operational trial results on page 48.

MAN fitted a Lucas Kienzle speedlimiter that can be reset below its 104km/h top limit. It operated very smoothly and with little fluctuation as the tacho charts show.

This and prudent use of the flap-type exhaust brake helped to return an overall 39.91it/100km (7.08mpg) at a respectable 70. 6km/h (43. 9mph).

In near-ideal weather conditions with a fully-laden combination, the 20.331 returned almost 34.3 lit/100km (8.3mpg) on the northern A5, M6 and A74 first leg of our three-day test.

Its very good overall performance was only marred by the severe "A" road section in Northumberland between Rochester and Nevilles Cross where consumption fell to 56.31it/100km ( 5. Ompg).

• TRANSMISSION

While its performance is not as startling as the 4x2 19.361, the 20.331's turn of speed is enhanced by the easy use of the Twin Splitter gearbox.

Each of the four gear stick positions in the "H" gate accounts for three successive ratios which are selected simply by moving the three-positioned splitter button and breaking the driving torque in the box with deliberate use of the accelerator pedal. Whole stick movements can be achieved in the same way.

Once familiar with the box, the use of MAN's crook-like gear lever is reserved for town centres or on long sharp climbs where the driver relies on the box's inertia or "up-shift" brake. This involves the use of an air switch at the end of the clutch pedal travel to slow the gears down and synchronise them very quickly.

In practice it works extremely well, allowing for snappy selection when required.

While it is nearly impossible to fault the slick shifting of the Twin Splitter (a normal production unit with its internally-mounted up-shift brake) the 20.331 struggled on the Blackhill climb.

Here it dropped to second low gear and took over six minutes to reach the summit. This was a full minute behind the Scania P112M 6x2 and the NTE 350powered Foden 6x4. Over this type of terrain the standard 4.04:1 fmal drive is unsuitable but MAN does offer alternatives; a 4.20 and the deepest 4.64:1. These improve claimed gradeability and give maximum top-geared speeds of 120 and 109km/h respectively.

The only variation between models seems to relate to the engine's rate of deceleration when the pedal is released. The MAN's 12 litre engine takes longer to slow down than the Foden 6x4 with its RR340Li and called for a more patient driving manner.

This is no real problem for the driver, especially on long motorway journeys such as the run between the A5/M6 and Gretna. Except for the fuelling stop at Burton no stick movement was necessary; just two ratios at Lancaster and one over Shap.

As well as reducing wear and tear on components it is easier on the driver, allowing him to adopt a relaxed driving style and concentrate more on traffic conditions.

• PERFORMANCE

The 20.331 is capable ol lugging down to 1,100rpm without fuss but will maintain high speeds on long gradients. Its other hill climb times are comparable with the best of the 246kW (330hp) units tested and the 20.331's acceleration times through the gears were impressive. "che Scania P112M is slightly quicker up to 801cm/h but the MAN 6x 2 is marginally faster than the Foden S106T 6x4 with RRLi340 and Twin Splitter. It is also on a par with the Mercedes-Benz 20.33 and nearly half-a-minute up on the Iveco 220.30.

• SUSPENSION

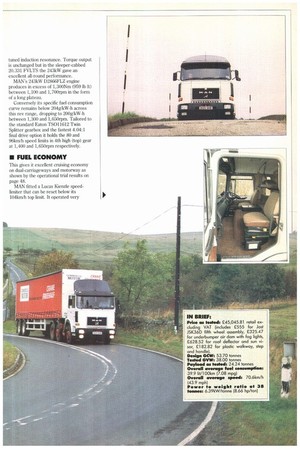

MAN is no stranger to air suspended vehicles, having built its first one 26 years ago. Its current system on the 20.331 comprises a pair of bellows on the second axle which are located by spring links, The drive axle uses two sets of air bags, mounted fore and aft with a top wishbone and anti-roll bar.

Air pressure varies between six and 10 bar depending on driving conditions and the imposed load. The first 10 tonnes is applied to the drive axle with the remaining weight accepted on the second one.

When running light — with less than 10 tonnes on the king pin — air pressure on the centre axle reduces to around 0.5 bar which is just sufficient to maintain tyre contact with the road.

Ride height is sensed and controlled automatically but MAN also provides a very useful manual control valve set at the side of the driver's seat. This allows for easy coupling of semi-trailers. An added feature is the exhauster or "mobility aid" button set to the left of the instruments which transfers most of the load onto the drive axle for about 20 seconds before quickly reflating. It proved most effective when restarting on the 25% test hill at MIRA. Working across severe terrain calls for precise, effective braking and in stark contrast to the 16.331 with its semi-automatic manual transmission (SAMT), the 20.331 twin steer excelled. On the test track it pulled up squarely without a trace of brakes locking on.

When CM road tested the 16.331 last month its steel suspension was noisy and emphasised the roll somewhat.

In sharp contrast, the 20.331's air suspension produced almost as smooth a ride over the worst of the A68 as it gave on the M6 motorway.

It undoubtedly contributed towards the cab's easy, well controlled ride and low noise levels.

For such a high-specification twin-steer unit with double-bunk sleeper cab the 20.331 in full trim achieves quite a low kerb weight of 7,760kg (as tested).

This compares most favourably with similar units such as those shown in the histograms. Foden's S106T with its double-drive axles, high roof sleeper cab and lots of aluminium is 330kg lighter while the LT10-290-powered SeddonAtkinson 301 6x2 (CM, February 2,

1985) and Leyland's 20.32 6 x 2 with NTE320 (CM, October 27, 1984) weighed 7,280 and 7, 710kg respectively.

Compared with other imported machines the 20.331 has a fairly narrow outer-axle spread which will suit semitrailers with short king-pin settings yet gives a tolerable 15.48m kerb to kerb turning circle.

• STEERING

With light and sensitive Zli‘ power steering the unit felt highly manouevrable at low speeds when fully laden. Having so much torque available down the rev range, however, it will need plenty of care when only part laden.

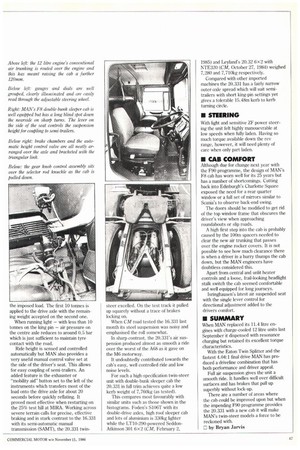

• CAB COMFORT

Although due for change next year with the F90 programme, the design of MAN's F8 cab has worn well for its 25 years but has a number of shortcomings. Cutting back into Edinburgh's Charlotte Square exposed the need for a rear quarter window or a full set of mirrors similar to Scania's to observe back-end swing.

The doors should be modified to get rid of the top window frame that obscures the driver's view when approaching roundabouts or slip roads.

A high first step into the cab is probably caused by the 100m spacers needed to clear the new air trunldng that passes over the engine rocker covers. It is not possible to see how much clearance there is when a driver in a hurry thumps the cab down, but the MAN engineers have doubtless considered this.

Apart from central and unlit heater controls and a loose, frail-looking headlight stalk switch the cab seemed comfortable and well equipped for long journeys.

Isringhausen's latest air suspended seat with the single lever control for directional adjustment added to the drivers comfort.

II SUMMARY

When MAN replaced its 11.4 litre engines with charge-cooled 12 litre units last September it dispensed with resonance charging but retained its excellent torque characteristics.

With the Eaton Twin Splitter and the fastest 4.04:1 final drive MAN has produced a driveline combination that has both performance and driver appeal.

Full air suspension gives the unit a smooth ride. It handles well over difficult surfaces and has brakes that pull up superbly without lock-up.

There are a number of areas where the cab could be improved upon but when the impending F90 programme provides the 20.331 with a new cab it will make MAN's twin-steer models a force to be reckoned with.

El by Bryan Jarvis