WORKSHOP AND GARAGE NOTES.

Page 179

If you've noticed an error in this article please click here to report it so we can fix it.

Useful Contributions From Our Driver and Mechanic Readers.

Two Useful Assembler's Tools.

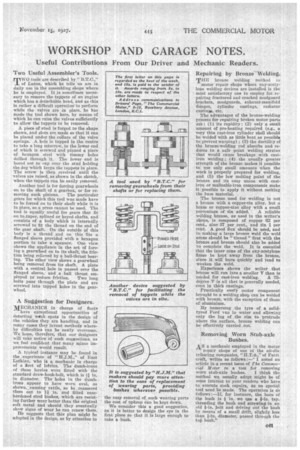

TWO tools are described by " B.T.C.," of Luton, which he tells us are in daily use in the assembling shops where he is employed. It is sometimes necessary to remove the tappets of an engine which has a detachable bead, and as this is rather a difficult operation to perform while the valves are In place, he has made the tool shown here, by means of -which he can raise the valves sufficiently to allow the tappets to be removed.

A piece of steel is forged to the shape shown, and slots are made so that it can be placed under the collars of the valve springs. A hole is tapped in the centre to take a long setscrew, to the lower end of which is screwed and pinned a piece of hexagon steel with tfornmy holes drilled through it. The tower end is bored out to cap over the stud holding the dog 'which keeps the tappets in place. The screw is then revolved until the valves are raised, as shown in the sketch, when the tappets can be easily removed.

Another tool is for forcing gearwheels on to the shaft of a gearbox, or for re moving such pinions. The particular gears for which this tool was made have to be forced on to their shaft while it is in place, so a press cannot be used. The tool is equally useful for gears that fit on to taper, splined or keyed shafts, and consists of a body which is internally screwed to fit the thread on the end of the gear shaft. On the outside of this body is a thread and on this fits a flanged sleeve provided with a hexagon portion to take a spanner. One view thaws the appliance in the act of forcing a gearwheel on to its shaft, the friction being relieved by a ball-thrust bearing. The other view shows a gearwheel being removed from its shaft. A plate with a central hole is passed over the flanged sleeve, and a ball thrust em ployed to reduce friction. Two long bolts pass through the plate and are screwed into tapped holes in the gearwheel.

A Suggestion for Designers.

MECHANICS in charge of fleets have exceptional opportunities of detecting weak spots in the design of the vehicles they are handling, and in many cases they invent methods whereby difficulties can be easily overcome. 1Ve hope, therefore; that our designers will take notice Of such suggestions, as we feel confident that many minor improvements would result.

A typical instance may be found in the experience of " H.J.111.," of East Lothian, who is a mechanic in charge of a fleet of lotries. The dumb-irons of these lorries were fitted with the standard draw-hook-bolt, which is

in diameter. The' holes in the dumbirons appear to have worn oval, as shown, causing rattle, so he, reamered them out to lf in. and fitted casehardened steel bushes, which are resisting further wear better than the original soft metal and should they eventually show signs of wear he can renew them.

He suggests that this plan might be adopted in the design, as by attention to the easy removal of such wearing parts the cost of upkeep can be kept down.

We consider this a good suggestion, as it is better to design the eye in the first place so that it is large enough to take a bush.

Repairing by Bronze Welding.

THE bronze welding method iii motor repair shops where oxy-acety

lene welding devices are installed is the most satisfactory one to employ for re

pairing fractured and cracked mudguard brackets, mudguards, exhaust-manifold flanges, cylinder castings, radiator. (=sting, etc.

The advantages of the bronze-welding process for repairing broken motor parts are : (1) its rapidity ; (2) only a small amount of pre-heating required (e.g., a very thin cast-iron cylinder shell should be welded with as little heat as possible to prevent warping) ; (3) the ductility of the bronze-welding rod absorbs and reduces to a safe point welding strains that would cause breakage with eastiron welding ; (4) the usually greater strength of the bronze makes it possible to use only small amounts when the work is properly prepared for welding, and (5) the low melting point of the bronze and its easy union with castiron or malleable-iron components make it possible to apply it without melting the base material.

The bronze used for welding is not a bronze with a copper-tin alloy, but a brass or copper-zinc alloy with a small

percentage of tin added. A reliable welding bronze, as used in the writer's shops, is composed of copper 62 per cent., zinc 37 , per .cent., and tin 1 per cent. A good flux should be treed, and in making a large bronze weld the weld areas should be " tinned "'first with the bronze and bronze should also be added to complete the weld. It is essential that the inner cone of the oxy-acetylene flame be kept away from the bronze, since it will burn quickly and tend to weaken the weld.

. Experience shows the writer that bronze will run into a smaller V than is needed for cast-iron welding. A 75degree V is all that is generally needed, even in thick castings.

Practically every motor component brought to a welding shop can be welded with bronze, with the exception of those of aluminium.

By immersing the tyre of a solidtyred Ford van in water and allowing only the lug of the rim to protrude above the surface, bronze welding can be effectively carried out.

Removing Worn Stub-axle Bushes.

AS a mechanic employed in the motor repair shops of one of the oil-dis tributing companies, " H.T.S.," of Patri croft, writes as follows :—" I noted an article in a recent issue of The Commercial Motor re a tool for removing worn stub-axle bushes. I think the method we usually adopt might be of some interest to your readers who have to execute such repairs, as no special tool need be made. The operation is as follows :—If, for instance, the bore of the bush is 1 in. we use a fin. tap. threading the bush and screwing in an old fin. bolt and driving out the bush by means of a small drift, slightly less than fin. diameter, passed through the top bush."