THE EQUIPMENT OF THE IGARAGE.

Page 174

Page 175

Page 176

If you've noticed an error in this article please click here to report it so we can fix it.

The Needlessness of Expensive Machine Tools. Emergency Plant and a Few Useful Makeshifts.

By a Maintenance Engineer.

TIIE equipment of the garage is a matter that has hardly had the attention bestowed upon it that it merits. The writer, who has had opportunities for investigating the equipment and the resultant methods with which repair and maintenance work in connection, with commercial vehicles are carried out has, in the majority of cases, found it poor and inefficient. Poor equipment means high labour charges for work done, and many of the disputes which are so common in connection with such charges might be avoided if more attention were given to the equipment.

The writer is able to speak from the point of view of one who has actually run a repair shop for years, also from the point of view of one who has had to investigate the bills and charges for repair work done in various parts of the country. The repairing of_ motors is by no means a highly remunerative business, yet the complaints of ens-' tomers that they have been overcharged for such work are probably more common than in any other class. Is there not some reason for this? In the opinion of the writer it is often due to people trying to do work without the proper tools.

In the case of the large fleet owned by an influential bus company or wealthy firm, there is no excuse for a poorly equipped garage, although such garages are by no means uncommon. The writer knows of a case where a man was expected to keep a fairly large fleet of buSes in order with an equipment which cost less than £100 all told. Garages may be divided, so far as equipment goes, roughly into three classes: (I) The large fleet garage ; (2) the garage of the man who earns his living by doing repair work ; and (3) the Colonial garage.

The Large Fleet Garage Equipment.

The equipment of the garage where a large fleet is dealt with, to take the first class we have specified, is a comparatively simple matter, as such a fleet does not, or should not, consist of a wide range of vehicles of different makes and ages. In such a case there is not a great need for machines such as lathes, milling machines, grinding and casehardening plant, as the work to be done is seldom more

than the removing or replacing of some part, as with a fleet of the kind the keeping of an adequate stock of spares is a simple matter, renewal being more economical and more satisfactory than trying to make the old part good again. In such a ease, the outfit comsists more of a plant for cleaning, lubricating and handling. The handling can be greatly assisted by a full set of the necessary jacks suitable for lifting the various parts, frames for holding engines whilst being overhauled, etc. Such an outfit means a capital outlay which a large concern can, and should, bear, and which will pay for itself many times over if the fleet is large enough. Such an equipment can easily be selected from the catalogues of the various firms who cater for this class of business.

The Small Garage and Repair Shop.

The equipment of the garage of a man who lives on a local repairing trade is one that requires judgment to select. It is very well to tell him that he ought to have this and he ought to have that, but, to put the matter plainly, he often has not the capital necessary for a very elaborate equipment; consequently he has to do the best he can on limited means, as, in many localities, the trade would no repay him for too large a capital expenditure. As designs improve and stocks of spare parts become more general, the more extensive repairing of motors (as distinct from 'part replacement) will gradually shrink. Many garage proprietors have laid out money on such, equipment as milling machines, case-hardening furnaces and even the costly plant necessary fdr grinding operations, only to find that the call for the use of such equipment is gradually becoming less as time goes on.

Therefore a modified equipment is the more likely to prove a profitable investment. A few hints on hew to deal with special jobs with a home-made or improvised equipment may be useful, and it is with the idea of saving the small man unnecessary expenditure that the notes on such matters are given later on in this article. Although improvisations, they will be quite practical.

The Colonial and Overseas Repair Shop.

The equipment of a repair slum in a Colony or overseas Dominion should differ in many respects from one in this country, as in such a case the plant is often called upon to tackle agricultural machinery and general engineering. Consequently, machinery of a heavier and more varied class is needed. In some cases the motor-re.pair branch is a smaller business than the engineering, and' inthose instances a knowledge cf a few useful makeshifts may be welcomed. • Some Hints on Home-made and Improvised Equipment.

It is necessary that all who cater for the repair of commercial vehicles should have some means for bringing to their garage a disabled lorry. Where the volume of trade will warrant the outlay, a ready-made equipment is undoubtedly best, but in the case of the smaller man the rig shown in one of our illustrations will answer well and can be made at a very low cost.

If some old damaged side-members are available they will answer the purpose, but where they are not at hand ordinary channel steel will do. This tackle can be laid on the floor of any ordinary lorry, the ends being held down by bolts. Ordinary chain' blocks and falls will do the lifting as well as anything else, and they can be used also for other purposes. If room is a consideration, the arrangement can easily be made so that it can be unbolted and rest flat against a wall.

A Useful Press from Scrap Parts.

Where the trade warrants it, a press made for the special requirements of motor work is undoubtedly best, provided it be large enough to tackle commercial-vehicle jobs, which require a much heavier press than one merely suitable for private car work, but for the small man a very useful makeshift can be made as follows:— Somewhere in the roof of the garage fix an ordinary flanged wheel that will take a stout rope. To the end of this rope attach any heavy bar, such as an old live axle. Procure a piece of tube that will allow the bar to elide freely through it, and a very good substitute for a press will be the result. Place the part to be operated upon on any heavy article, such as an anvil, pack up the wheel or whatever has to be removed from a shaft and place the end of the tube over the shaft, and by raising and dropping the bar on it the most obstinate cases can be dealt with. To remove a bush, turn a plug to fit in the bush, leaving a shoulder slightly smaller than the bush and an extension which goes a little way up the tube, and by repeated blows any busk can be driven out. Blows of this kind, if repeated often enough, will move almost anything, and in some cases will do what a press will fail to do unless it be a very powerful one.

A Temporary Furnace for Case-hardening.

There are cases where some article has to be casehardened, and it is useful to know how this can be done without a proper furnace for heating the muffle and keeping the heat up for the necessary time, which may be frbin two to four hours, according to OA depth to which the hare shell is to penetrate. '

For sueh articles as shafts a piece of tube makes a very good muffle, and if packed with the necessary carbon, the ends being closed with clay and a vent hole being provided, all is ready for heating. Bricks should then be placed round an area considerably larger than the muffle, and a fire of wood and shavings lighted. When this is well 'alight coke can be added and more bricks built up until a fairly hot fire is madm The muffle can then be laid in the fire and covered with more coke, and if the fire be built on the ground and without any ingress at the floor for air, as with firebars, the heat will never be more than is needed for casehardening. A test piece, notched for breaking should be placed in the muffle so that the depth to which the carburizing has penetrated can be ascertained. It is best to Some Useful Lathe Tips for Motor Work.

In a garage where no grinding machinery is installed it is sometimes necessary slightly to enlarge a hole in some part, and when such a part is hardened it is not possible to bore or scrape out the hole. Some form of lapping has, therefore, to be resorted to. An accompanying illustration shows a very simple way of doing such a job. A piece of wood is held in a chuck and turned to a size slightly smaller than the hole. It is then split with a saw along its whole length and a piece of emery cloth tucked into the split. The job is then placed on the lap and the poppet centre will expand it until the necessary diameter for enlarging the bole is obtained.

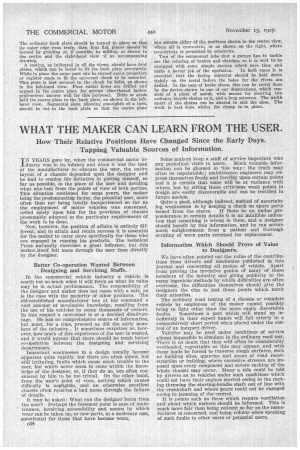

The universal or self-centring chuck is to be found in even the most poorly equipped garage, but it is often the case that some part, such as a gearwheel, has to be bushed and, when held by the boss, the teeth may not be found to be running truly. In such a case, an independent or fourjaw chuck is necessary, but one is not often to be found as its cost does not justify its inclusion in the outfit. A most useful compromise which is cheap to produce and which can be made by almost anyone is described below. In some cases it is even more useful than a full equipment of both kinds of chuck, as it provides simple means whereby a universal chuck can instantly be converted to an independent or adjustable chuck without removing the job from the jaws. The device consists of a plate of cast-iron interposed between the ordinary back plate and the chuck body. The ordinary back plate should be turned in place so that its outer edge runs truly, then four flat places should be formed by grinding or, if possible, by milling, as shown in the centre and the right-hand view If an accompanying drawing.

A casting, as indicated in all the views, should have four plates, which can be bored to fit the back plate accurately. While in place the outer part can be turned and a projection or register made to fit the universal chuck to be mounted. This plate is best secured to the chuck by bolts, as shown in the left-hand view. Four radial holes are drilled and tapped in the centre plate for screws (fine-thread hollow grub-screws answer well for this purpose). Bolts or studs hold the centre plate to the back plate, as shown in the lefthand view. Segmental slots, allowing one-eighth of a turn, should be cut in the back plate so that the centre plate can fts$11111e either of the positions shown in the centre view, where all is concentric, or as shown on the right, where eccentricity is permitted by setscrews.

Two of the commonest jobs that a garage has to tackle are the refacing of brakes and clutches, so it is well tot be equipped with some simple devices which save time and make a better job of the operation, In both cases it is essential that the facing material should be held down tightly on the metal before the holes for the rivets are drilled. In the ease of brake shoes, this can be easily done by the device shown in one of our illustrations, which consists of a plate of metal, with means for securing two ordinary bicycle chains to it, and a long setscrew. The width apart of the chains can be altered to suit the shoe. The work is best done whilst the clamp is in place.