THE DESIGNER'S EYE ON MAINTENANCE COSTS.

Page 171

Page 172

Page 173

If you've noticed an error in this article please click here to report it so we can fix it.

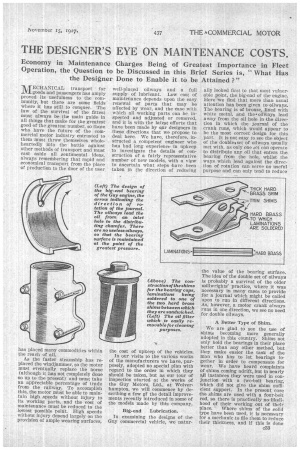

Economy in Maintenance Charges Being of Greatest Importance in Fleet Operation, the Question to be Discussed in this Brief Series is, "What Has the Designer Done to Enable it to be Attained ?"

m_CECHANICAL transport for goods and passengers has amply proved its usefulness to the community, but there are some fields where it has still to conquer. The law of the survival of the fittest must always be the main guide in all things that make for the greatest good of the greatest number, so those who have the future of the commercial motor industry entrusted to them must throw themselves wholeheartedly into the battle against other methods of transport and must cast aside all sentimental ideas, always remembering that rapid and economical transport from the place of production to the door of the user

has placed many commodities within the reach of all.

As the faster steamship has replaced the windjammer, so the motor must eventually replace the horse (although it has not completely done so up to the present) and must take an appreciable percentage of trade from the railway. To accomplish this, the motor must be able to maintain high speeds without injury to Its working parts, and the cost of maintenance must be reduced to the lowest possible point. High speeds without injury depend largely on the provision of ample wearing surfaces,

well-placed oilways and a full supply of lubricant. Low cost of maintenance depends upon the easy renewal of parts that may be affected by wear, and the ease with which all working parts can be inspected and adjusted or removed, and it is with the latest efforts that have been made by aur designers in these directions that we propose to deal here. We have, therefore, instructed a competent engineer who has had long experience in upkeep to investigate the details of construction of a fairly_ representative number of new models, with a view to ascertain what steps have been taken in the direction of reducing

the cost of upkeep of the vehicles.

In our visits to the various works of the manufacturers we have, purposely, adopted no special plan with regard to the order in which they should be taken, but as our tour of inspection started at the works of the Guy Motors, Ltd., at Wolverhampton, we will commence by describing a few of the detail improvements recently introduced in some of the models made by this company.

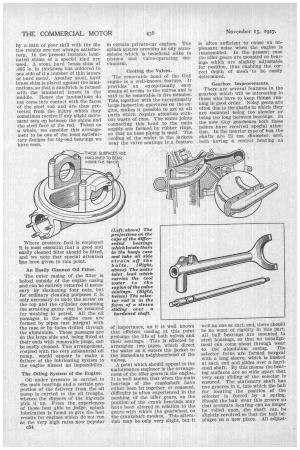

Big-end Lubrication.

In examining the designs of the Guy commercial vehicle, we natur ally looked first to that most vulnerable point, the big-end of the engine. Here we find that more than usual attention has been given to oilways. The bearing is of bronze, lined with white metal, and the•oilways lead away from the oil hole in the direction in which the journal of the crank runs, which would appear to be the most correct design for this part. It is not easy to see the object of the doubles set of oilways usually met with, as only one set can operate to distribute any oil that enters the bearing from the hole, whilst the ways which lead against the direetion of rotation can serve no useful purpose and can only tend to reduce

the value of the hearing surface. The idea of the double set of oilways is probably a survival of the older millwrights' practice, where it was necessary in many cases to provide for a journal which might be called upon to run in different directions. As, however, a motor crank always runs in one direction, we see no need for double oilways.

A Better Type of Shim.

We are glad to see the use of shims becoming more generally adopted in this country. Shims not only hold the bearings in their place better than any other method, but they make easier the task of the man who has to let bearings together in order to compensate for wear. We have heard complaints of shims coming adrift, but in nearly all instances they were used in conjunction with a two-bolt bearing, which did not give the shim sufficient support. In the present case the shims are used with a four-bolt rod, so there is practically no.likelihood of their working out of their place. Where shims of the solid type have been used, it is necessary for a mechanic to file them to reduce their thickness, and if this is done by a Dian of poor skill with the file the results are not always satisfactory. In the present 'instance laminated shims of a special kind are used. A stout, hard brass shim of .035 in. in thickness has soldered to one side of it a number of thin layers of hard metal. Another stout, hard brass shim is placed against the laminations, so that a sandwich is formed with the laminated layers in the middle. Hence the laminations do not come into contact with the faces of the steel rod and are thus protected from the injury which they sometimes receive if any slight movement sets up between the shims and the steel face of the rod. Taken as a whole, we consider this arrangement to be one of the most satisfactory designs for-big-end bearings we have seen, Where pressure feed is employed It is most essential that a good and easily cleaned filter should be fitted, and we note that special attention has been given to this point.

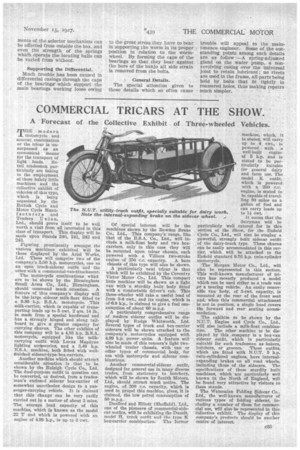

An Easily Cleaned Oil Filter.

The outer casing of the filter is bolted outside of the engine casing and can be entirely removed if necessary by slackening four nuts, but for ordinary cleaning purposes it is only necessary to undo the screw on the top and the cylinder containing the straining gauze can be removed for washing in petrol. All the oil passages in the engine ease are formed by pipes cast integral with the case or by holes drilled through the aluminium. These passages are on the large side and, being fitted at their ends with removable plugs, can be easily cleaned. This arrangement, coupled with the very substantial oil pump, would appear to make a failure of the lubricating system to the engine almost an impossibility.

The Oiling System of the Engine.

Oil under pressure is carried to the main bearings and a certain proportion of the delivery from the oil pump is carried to the oil troughs, whence the dippers of the big-ends pick it up. Prom the experiences of those best able to judge, splash lubrication Is found to give the best results for engines which do not run at the very high rates now popular c34 in certain private-car engines. The splash system provides an oily atmosphere which is beneficial alike to pistons and valve-operating mechanism.

Cooling the Valves.

. The removable head of the Guy engine is a well-known feature. It provides an exceptionally easy means of access to the valves and is said to be removable in five minutes. This, together with the exceptionally large inspection apertures on the engine, makes it possible to get at all parts which require attention without waste of time. The water joints connecting this head to the main supply are formed by rubber rings, so that no hose piping is used. The cooling of the water in the jackets near the valve seatings is a feature of importance, as it 's well known that efficient cooling at this point prolongs the life of both valves and their seatings. This is effected by arranging two pipes, which' direct the water as it enters the jacket to the immediate neighbourhood of the valves.

A point which should appeal to the maintenance engineer is the arrangement of the idler gears in the engine. It is well known that when the main bearings of the crankshaft have either been let together or renewed, difficulty is often experienced in the meshing of the idrer gears, as the position of the crank bearings may have been altered in relation to the gears with which the gearwheel on the crankshaft meshes. This alteration may be only very slight, but it is often sufficient to cause an unpleasant noise when the engine is reassembled. In the present case the idler gears are mounted on bearings which are slightly adjustable for position, thus enabling the correct depth of mesh to be easily determined.

Gearbox Improvements.

There are several features in the gearbox which will be interesting to those who have to keep things running in good order. Noisy gears are often due to the shafts in which they are mounted being too slender or being too long between bearings. In the new Guy gearboxes both these points have received special attention. In the heavier type of box the shafts are 2i ins, diameter, and, both having a central bearing as well as one at each end, there should be no want of rigidity in this part. All ball bearings are mounted in steel housings, so that no misalignment can come about through wear to the aluminium casing. The selector forks are formed integral with a long sleeve, which is bushed at each end and slides over a hardened shaft. By this means the bearing surfaces are so wide apart that very easy sliding of the selector is ensured. The stationary shaft has two grooves in it, into which the ball for locating the position of the selector is forced by a spring. Should the ball wear this groove so that accurate locating can no longer be relied upon, the shaft can be slightly revolved so that the ball impinges on a new place. All adjust

ments of the selector mechanism can be effected from outside the box, and even the strength of the springs which operate the locating balls can be varied from without.

Supporting the Differential.

Much trouble has been caused in differential casings through the caps of the bearings' which support the main bearings working loose owing

to the great stress they have to bear in supporting the worm in its proper position in relation to the wormwheel. By forming the caps of the bearings so that they bear against the bore of the banjo all side strain is removed from the bolts.

. General Details.

The special attention given to those details which so often cause trouble will appeal to the maintenance engineer. Some of the outstanding points among such details are as follow :—A spring-adjusted • gland on the water pump, a nonrevolving casing over the universal joint to retain lubricant ; no rivets are used in the frame, all parts being held by bolts that fit tightly in reamered holes, thus making repairs much simpler.