INGENUITY IN TIPPING-TRAILER OPERATION.

Page 154

Page 155

If you've noticed an error in this article please click here to report it so we can fix it.

Interesting Method of Using the Power of the Tractor Engine to Operate the Lifting Gear of the Tipping Trailer Drawn by It. An

fr HE uses of the commercial

vehicle are almost limitless. For years horse transport has held sway an the hundred and one variations of haulage work. Gradually, however, the homed vehicle is being superseded by mechanical transport 'and, as competition becomes keener keener and keener, these vehicles have to be improved to cope with modern "high pressure" conditions.

One side connected primarily with heavy transportation concerns the movement of heavy loads over short distances, an example being the transportation of coal for gas companies who do not possess their own railway sidings. Very often the distance from the siding to the works is Jess than half a mile, and it seldom happens that more than a mile has to be EAS covered at ene journey. Here is a problem, then, requiring the minimum of time to be spent on loading and unloading in order to get transportation costs down as low as possible.

We have recently had an opportunity of inspecting a 5-6-tan trailer designed to be drawn by a Fordson tractor, manufactured by the Eagle Engineering Co., Ltd., of Warwick. Before describing the vehicle in detail it would seem opportune to give a few particulars as to its general utility. One particular municipal authority states that by employing relays of these trailers, drawn, of course, by one tractor, the total

cost for hauling (over a distance of half a mile) works out ,at 1a, -3d.

per ton. This cost, incideutallY, ' includes all overhead charges—debreciation of capital, taxes. wages, etc., and is really a conservative estimate. It is possible for three men to load up three loads of 6 tons each per hour and, with a half-mile journey, the daily tonnage works out at about 100 without overworking the men.

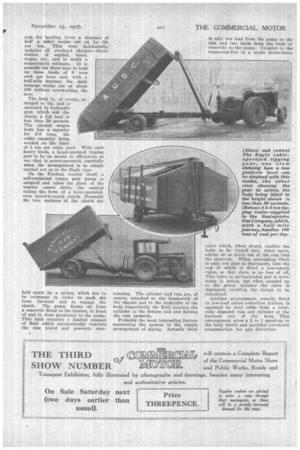

The body is, of course, arranged to tip, and is operated by hydraulic gear, which will discharge a full load in less than 30 seconds. The normal wagon body has a capacity far 5-6 tons, the cubic capacity being worked on the basis of 1 ton per cubic yard. With such heavy loads, a hand-operated tipping gear is by no means so efficacious as one that is power-operated, especially when the arrangement is so :simply carried out as in the Eagle type.

On the Fordson tractor itself, a self-contained rotary gear pump is adopted and takes the place of the tractor power drive, the control taking the form of a lever-operated, cone metal-to-metal clutch. Normally the two surfaces of the clutch are held apart by a spring, which has to be overcome in order to push the lever forward and to engage the clutch. The pump draws oil from a reservoir fitted to the tractor, in front of and in close prcapimity to the pump. This tank contains a limited amount of fluid which automatically restricts the ram travel and prevents over running. The cylinder and ram are, of course, attached to the framework of the chassis and to the underside of the body respectively, the fluid entering the cylinder at the bottom end and forcing the ram upwards.

Probably the most interesting feature concerning the system is the simple arrangement of piping. Actually there is only one lead from the pump to the ram and two leads from the tank or reservoir to the pump. Coupled to the Pump-ram-line is a single screw-down valve which, when closed, enables the body • to be tipped and, when open, 'allows oil to drain out of the ram into the reservoir. When uncoupling there is only one pipe to disconnect, into the end of which is fitted a non-return valve, so that there is no loss of oil. This valve is spring-loaded and is automatic in action, but when coupled up to the power cylinder the valve is depressed, ennbling the circuit to be completed.

Another arrangement, usually fitted to low-load refuse collection trailers, is operated by steel cable from a vertically disposed ram and cylinder at the forward end of the body. This arrangement gives a 2 to 1 speed-up to the body travel and provides automatic compensation for any distortion.