VULCAN'S NEW SIX-WHEELER.

Page 131

Page 132

If you've noticed an error in this article please click here to report it so we can fix it.

A Chassis Designed to the W.D. Specification No. 30 and Capable for Commercial Purposes of Carrying 4-5 Tons Over Good Roads.

DRENTG a visit which we paid a few weeks ago to the Crossens works of the Wean Motor and Engineering Co. (1906), Ltd., we saw under construction the first examples of the Vulcan medium-type, rigid-frame six-wheeler, which is known as the type V.S.M., and is designed in accordance with the W.D. Specification Number 30. This calls for a vehicle capable of carrying a load of 3 tons over good roads and 2 tons whore the going is bad, whilst for commercial purposes it can carry between 4 tons and 5 tons and 2 tons and 3 tons respectively.

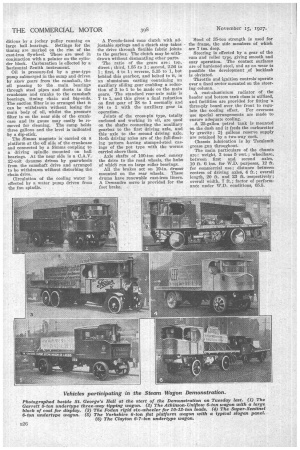

The suspension of the bogie axles is such that under all conditions of driving effort the pressure of the driving wheels on the ground remains equal, although, of course, the usual wire hawser slings are provided, and these prevent the axles dropping to an excessive degree when the vehicle is passing over steep-sided obstructions. A torque arm is, of course, employed between each axle and a strong tubular crossmember of the frame, these members having universal action. The rear suspension is by two pairs of semi-elliptic springs, inverted and carried on a fulcrum bracket pivoted in line with the axle centres. Torsional stresses are prevented by allowing the spring carriers on the axles to work on well-lubricated spherical bearings on the axle tubes, a certain amount of side-play being permitted to these bearings, whilst glands prevent the entry of dirt or water.

The standard tyre equipment is single 38-in. by 7-in, pneumatics-on all wheels, but, if required, twin tyres may be fitted to the rear wheels of the driving axles so that a light, pressed-steel track belt may be placed around the driving wheels at each side ; in this case the tyres are 36-in. by 6-in. pneumatics.

Dealing with the general specification, the power unit has four cylinders , of 110 mm, bore and 140 ram. stroke cast en bloc, and having a capacity of 5,320 c.c. It develops 39 b.b.p. at 1,000 r.p.m. and 53 b.h.p. at 1,400 r.p.m. The head is detachable and has four lugs for lifting purposes, To provide rigidity, the bolts for the main bearings are carried right through the case to secure the cylinder block, and the unit, which is separate from the gearbox, is three-point supported. A 40-ton steel stamping is employed for the crankshaft, which has a doublethrust washer. The connecting rods are of similar material with two-bolt caps and bushed small-ends. Aluminium alloy pistons are provided as standard.

The camshaft is of C.N.Y. steel and is supported in three large bearings, whilst the valves are of 3 per cent. nickel-steel and operated by silent roller tappets working in oil mist. The camshaft and magneto are driven by a Renolds silent chain 1.6 in. wide and

in. pitch. Provision is made for external adjustment under running con ditions by a jockey pulley running on large ball bearings. Settings for the timing are marked on the rim of the cast-iron flywheel. These are used in conjunction with a pointer on the cylinder block. Carburation is effected by a horizontal Zenith instrument.

Oil is pressure-fed by a gear-type pump submerged in the sump and driven by skew gears from the camshaft, the oil passing to the main bearings through steel pipes and ducts in the crankcase and cranks to the camshaft bearings, timing chain and big-ends. The suction filter is so arranged that it can be withdrawn without losing the main body of oil, whilst the pressure filter is on the near side of the crankcase and its gauze may easily be removed for cleaning. The sump holds three gallons and the level is indicated by a dip-stick.

The Simms magneto is carried on a Platform at the off side of the crankcase and connected by a Simms coupling to a driving spindle mounted on ball bearings. At the near side is a C.A.V. 12-volt dynamo driven by gearwheels from the camshaft drive and arranged to be withdrawn without disturbing the chain drive.

Circulation of the cooling water is effected by a water pump driven from the fan spindle. A Ferodo-faced cone clutch with adjustable springs and a clutch stop takes the drive through flexible fabric joints to the gearbox. The clutch may be withdrawn without dismantling other parts.

The ratio of the gears are: top, direct ; third, 1.55 to 1; second, 2.56 to 1; first, 4 to 1; reverse, 5.35 to 1, but behind this gearbox, and bolted to it, is an aluminium casting containing an auxiliary sliding gear enabling a reduction of 3 to 1 to be made on the main gears. The standard rear-axle ratio is 7 to 1, and this gives a final reduction on first gear of 28 to 1 normally and 84 to 1 with the auxiliary gear in operation.

Joints of the cross-pin type, totally enclosed and working in oil, are used on the shafts connecting the 'auxiliary gearbox to the first driving axle, and this -axle to the second driving axle. Both driving axles are of the fulI-floating pattern having stamped-steel casings of the pot type with the worms carried above them.

Axle shafts of 100-ton steel convey the drive to the road wheels, the hubs. of which run on large roller bearings.

All the brakes act on 19-in. drums mounted on the rear wheels. These drums have renewable cast-iron liners. A Dewandre servo is provided for the foot brake. -Steel of 35-ton strength is used for the frame, the side members of which are 7 ins. deep.

Steering is effected by a gear of the cam and roller type, giving smooth and easy operation. The contact surfaces are of hardened steel, and as no wear is possible the development of backlash is obviated.

Throttle and ignition controls operate over a fixed sector mounted on the steering column.

A cast-aluminium radiator of the header and bottom tank class is utilized, and facilities are provided for fitting 'a three-ply board over the front to regu

late the cooling effect. For overseas use special arrangements are made to ensure adequate cooling.

A 25-gallon petrol tank is mounted on the dash and it feeds the carburetter by gravity ; 21 gallons reserve supply are retained by a two-way cock.

Chassis lubrication is by Tecalemit grease gun throughout.

The main particulars of the chassis are : weight, 3 tons 5 cwt.; wheelbase, between first and second axles, 10 ft. 6 ins. for W.D. purposes, 12 ft. for commercial use ; distance between centres of driving axles, 4 ft.; overall length, 20 ft. and 23 ft. respectively ; overall width, 7 ft. ; factor of performance under W.D. conditions, 65.5.