New Range of Tandem

Page 86

Page 87

If you've noticed an error in this article please click here to report it so we can fix it.

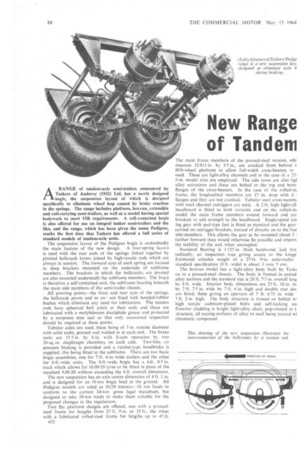

(Right) On platform models with rolled-steel

T rom as erscraammese, sberxatceknest ts oonns ARANGE of tandem-axle semi-trailers announced by Taskers of Andover (1932) Ltd. has a newly designed bogie, the suspension layout of which is designed specifically to eliminate wheel hop caused by brake reaction in the springs. The range includes platform, boxvan, extensible and coil-carrying semi-trailers, as well as a model having special bodywork to meet TIR requirements. A self-contained bogie is also offered for use on integral tanker semi-trailers and the like, and the range, which has been given the name Pedigree, marks the first time that Taskers has offered a full series of standard models of tandem-axle units.

The suspension layout of the Pedigree bogie is undoubtedly the main feature of the new design. A four-spring layout is used with the rear ends of the springs linked together by pivoted bellcrank levers joined by high-tensile rods which arc always in tension. The forward eyes of each spring are located in deep brackets mounted on the underside of subframe members. The brackets in which the bellcranks are pivoted are also mounted underneath the subframe members. The bogie is therefore a self-contained unit, the subframe locating beneath the main side members of the semi-trailer chassis.

All pivoting points—the front and rear eyes of the springs, the bellcrank pivots and so on—are fitted with bonded-rubber bushes which eliminate any need for lubrication. The tension rods have spherical ball joints at their ends and these are lubricated with a molybdenum disulphide grease and protected by a neoprene dust seal so that only occasional inspection should be required at these points.

Tubular axles are used, these being of 5 in. outside diameter with solid stubs, pressed and welded in at each end. The brake units are 15.5 in. by 6 in. with S-cam operation by two 20-sq. in. diaphragm chambers on each axle. Two-line, air pressure braking is provided and a ratchet-type handbrake is supplied, this being fitted to the subframe. There are two basic bogie assemblies, one for 7-ft. 6-in.-wide trailers and the other for 8-ft.-wide units. The 8-ft.-wide bogie has a 6,ft. 0.5 in. track which allows for 10.00-20 tyres to be fitted in place of the standard 9.00-20 without exceeding the 8 ft. overall dimension.

The new suspension has an axle centre dimension of 4 ft. 1 in. and is designed for an 18-ton bogie load at the ground. All Pedigree models are rated as 16/20 tonners-16 ton loads to conform to the current 24-ton gross legal maximum, but designed to take 20-ton loads to make them suitable for the proposed changes in the regulations.

Two flat platform designs are offered, one with a pressedsteel frame for lengths from 25 ft. 9 in. to 33 ft., the other with a fabricated roiled-steel frame for lengths up to 45 ft.

n52

The main frame members of the pressed-steel version, whi measure 12,813 in. by 3.5 in., are cranked from 'behind t fifth-wheel platform to allow full-width cross-bearers to used. These are light-alloy channels and in the case of a 259-in, model nine are employed. The side raves are also ligl alloy extrusions and these are bolted to the top and bottc flanges of the cross-bearers. In the case of the rolled-stt frame, the longitudinal members are 17 in. deep with 4 , flanges and they are not cranked. Tubular steel cross-membt with steel channel outriggers are used. A 2-ft. high light-all, headboard is fitted to both versions and on the rolled-str model the main frame members extend forward and car brackets to add strength to the headboard. Single-speed Ian ing gear with pad-type feet is fitted as standard and the gear carried on outrigger brackets, instead of directly on to the frat side-members. This allows the gear to be mounted about 5 farther forward than would otherwise be possible and impror the stability of the unit when uncoupled.

Standard flooring is 1,125 in. thick hardwood, laid lon: tudinally, an • inspection trap giving access to the kingp Estimated unladen weight of a 25-ft. 9-in, semi-trailer standard specification (8 ft. wide) is about 3 tons 5 cwt.

The boxvan model has a light-alloy body built by Taskt on to a pressed-steel chassis. The body is framed in extrud alloy sections and the standard size is 26 ft. 7-5 in. overall lent by 8 ft. wide. Interior body dimensions are 25 ft. 10 in. lo by 7 ft. 7-5 in, wide by 7 ft. 6 in. high and double rear dor are fitted, these giving an aperture of 7 ft. 6-75 in. wide 7 ft. 2 in. high. The body structure is riveted or bolted w, high tensile cadmium-plated bolts and self-locking nu Exterior cladding is bright light-alloy sheet, pop-riveted to t structure, all mating surfaces of alloy to steel being treated wi chromatic compound.

nderframing is extruded channel-section cross-bearers tred to steel brackets provided on the main frame at about . 6 in. centres. The bases of the sides are fitted with full;th alloy tub-rail sections and the flooring is 0-875 in. thick rlocking extruded alloy planking secured to the crossabers through auxiliary flanges. The front outer vertical iers are radiused at 4 in. and the roof is constructed with ;jai extruded-alloy, cant-rail sections incorporating a gutter ion. The rear of the body is framed in steel and the two ed doors are hung on three steel outrigger hinges so that 7 fold along the sides of the body when in the open position. entral heavy-duty, cam-type locking device is fitted.

standard form the boxvan semi-trailer weighs about 3 tons :wt. and optional extras offered include a hardwood floor, mber or light-alloy roller shutter instead of the rear doors, interior lining to the body of plywood or light-alloy sheet. interior height can be raised from 7 ft. 6 in. to 8 ft. and ies up to 33 ft. long, in 1-ft. increments, are available.

here are two versions of coil-carrier semi-trailer in the igree range; one has a 15-ton capacity, having a convenal frame, whilst the other is rated, as the other Pedigree lets, for 16/20 tons; this has a wide frame, the longitudinals ig located at the outside edges of the platform. The 15-ton lel uses a similar frame construction to the Pedigree form with its swan-neck main rails and so on, but the crossnbers are of steel and are welded to the main longitudinals, area of the coil well being suitably strengthened. The form is 26 ft. long by 7 ft. 6 in. wide and the coil well is d with timber slats and can accept 6-ft.-diameter steel coils. tinged support is built into the bottom of the well which be raised to support cross-boarded tracks when the coils not being carried and so convert the unit to a flat-platform . special fitting is a prop assembly which is designed to rent the coils carried from spiralling out under braking acceleration forces. The 16120-ton coil carrier has the intage over the narrow-frame model that the well can be aer and, in fact, allows the centre of gravity of the coils ae lowered by about 6 in Because of the special design. this model the bogie sub-frame is not detachable. Estimated iden weights for the two coil-carriers are 3 ton 14,75 cwt. the 15-tonner and 3 ton 18-75 cwt. for the 16/20 ton model. he special T1R bodywork offered is of conventional design is based on the platform semi-trailers in the range. It sists of a 2-ft.-high headboard, drop sides and tailboard, porting a tubular metal framework with a headboard extent and removable wooden slats. A canvas tilt is secured by tics-covered steel wire threaded through evenly spaced eyes there is provision for sealing at the rear in accordance with regulations. The body framework can be removed if ; required to convert the trailer to a standard drop-sided ice. The final model in the range is the extensible chassis ch provides for three overall lengths-26 ft., 32 ft. and the maximum of 38 ft., whilst, as stated earlier, the Pedigree bogie is offered as a self-contained running gear for use on frameless tankers, vans and tipping semi-trailers.

Also announced by Taskers is a tandem-axle, air-suspension semi-trailer which, although using some components from the Pedigree range, differs in a number of respects. The floor is cross-boarded and steel side raves of special construction are used, whilst the main frame longitudinals are 15-in.-deep pressings. Vertical-lift landing gear, outrigged in the same way as the Pedigree design. is used and the axles and braking equipment are the same. The air suspension layout was designed by Taskers in conjunction with Dunlop. Double convolute air bellows are mounted at both sides of each axle. axle location being by quarter-elliptic leaf springs. These are mounted in brackets forward of the axles and act as trailing arms. Two Panhard rods provide sideways location of the axles and bump stops inside the bellows and check straps on the outside prevent excessive up and down axle movement. The bump stops are sufficiently strong to support the laden vehicle in the event of failure of the suspension bellows. Dampers are fitted on each side of the axles, behind the air bellows.

Air for the bellows is drawn from the semi-trailer braking system, a pressure-regulating valve being fitted so that air for the bellows cannot be drawn from this system unless pressure in the brake reservoir is above 65 psi.

The general design of the Pedigree range was finalized only recently, although original platform models were built towards the end of last year and submitted to British Road Services Ltd. for approval. This was given and now B.R.S. has a number of platforms and coil-carriers in use. After service experience, a further 240 or so Pedigree tandem-axle semi-trailers of varying design have been ordered by B.R.S., Ltd. from Taskers so far this year, which is a good recommendation for the Pedigree design.

Whilst at Taskers getting details of the Pedigree design, took the opportunity to try out a boxvan-bodied model on a local aerodrome to assess the performance of the suspension. A Leyland tractive unit was used for this, the semi-trailer being unladen, and a creditable performance was given. Maximumpressure braking stops were made from 20 and 30 m.p.h. on a surface which had slight corrugations and although there was some slight bouncing of the semi-trailer back end--this. incidentally, was felt to be because of the tyres bouncing over the slight corrugations-there was no wheel hop of the usual type. There was, in fact. far more movement of the tractive unit, which bounced up and down alarmingly on one stop from 30 m.p.h.—so much so that the clipped-on cover of the battery which is located beneath the driver's seat, flew off. Compared with this, the semi-trailer behaved like a lamb.

A. J. P. WILDING, A.M.I.Mech.E. B53