Controlling Ignition Timing by Suction

Page 68

If you've noticed an error in this article please click here to report it so we can fix it.

A Rgsum of Recently Published Patent Specifications

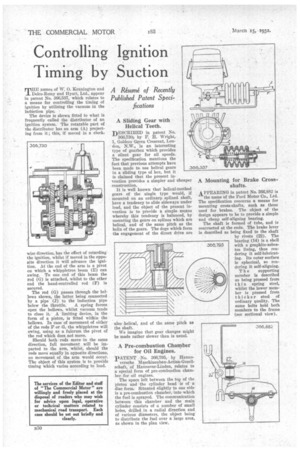

A Sliding Gear with Helical Teeth. THE names of W. 0. Kennington and Delco-Remy and Hyatt, Ltd.; appear in patent No. 366,537, which relates to a means for controlling the timing of ignition by utilizing the vacuum in the induction pipe.

The device is shown fitted to what is frequently called the distributor of an ignition system. The rotatable part of the distributor has an arm (A) projecting from it ; this, if moved in a clock wise direction, has the effect of retarding the ignition, whilst if moved in the opposite direction it will advance the ignition. At the end of the arm is a pivot on which a whippletree beam (E) can swing. To one end of this beam the rod (G) is attached, whilst to the other end the hand-controlled rod (F) is secured.

The rod (G) passes through the bellows shown, the latter being connected by a pipe , (J) to the induction pipe

below the throttle. A spring forces open the bellows, whilst vacuum tends to close it. .A limiting device, in the form of a piston., is fitted within the bellows. In case of movement of either of the rods P or G, the whippletree will swing, using as a fulcrum the pivot of the rod which does not move.

Should both rods move in the same direction, full movement will be imparted to the arm, whilst; should• the rods move equally in opposite directions, no movement of the arm would occur. The object of this system is to provide timing which varies according to load. DESCRIBED in patent No.

366,730, by F. H. Wright, 1, Guiders Green Crescent, London, N.W., is an interesting type of gearbox which provides a silent gear for all speeds. The specification mentions the fact that previous attempts have been made to use helical gears in a sliding type of box, but it is claimed that the present invention provides a simpler and cheaper construction.

It is well known that helical-toothed gears of the single type would, if mounted on an ordinary splined shaft, have a tendency to slide sideways under load, and the object of the present invention is to provide a simple means whereby this tendency is balanced, by mounting the gears on splines which are helical, and of the same pitch as the helix of the gears. The dogs which form the engagement of the direct drive are also -helical, and of the same pitch as the shaft.

We imagine that gear changes might be made rather slower than is usuaL

A Pre-combustion Chamber for Oil Engines.

PATENT No. 366,795, by Hanna versche Maschinenbau-Actien-Gesellsehaft, of Hannover-Linden, relates to a special form of pre-combustion chamber for oil engines.

The space left between the top of the piston and the cylinder head is of a disc form. Situated slightly to one side is a pre-combustion chamber, into which the fuel is sprayed. The communication between this chamber and the main cylinder consists of a number of small holes, drilled in a radial direction and of various diameters, the object being to distribute the fuel over a large area, as shown in the plan view.

APPEARING in patent No. 366,882 is

the name of the Ford Motor Co., Ltd. The specification concerns a means for mounting cross-shafts, such as those used for brakes. The object of the design appears to be to provide a simple and cheap self-aligning bearing.

The shaft is formed of tube, and is contracted at the ends. The brake lever is described as being fixed to the shaft by rivets (22). The bearing (14) is a shell with a graphite-asbestos lining, thus rendering it self-lubricating. Its outer surface Is spherical, so rendering it self-aligning.

T h e supporting member is described as being pressed from thin spring steel, whilst the lower member is pressed from thicker steel of ordinary quality. The same bolts hold both members to the frame (see sectional view).