WONDERFUL FORESTRY WORK

Page 50

Page 51

Page 52

Page 53

If you've noticed an error in this article please click here to report it so we can fix it.

Modified Winch Gear and Improved Trailer Facilitate Forestry Operations with the Well known Latil KTL-type Tractor. Work

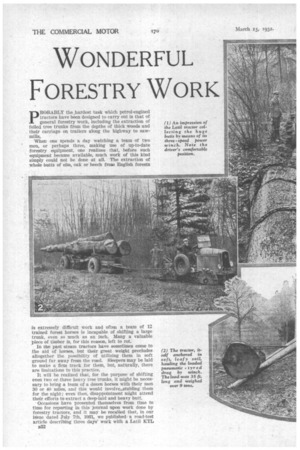

Accomplished which, Without Such an Appli ance, Would Have to be Left Undone PROBABLY the hardest task which petrol-engined tractors have been designed to carry out is that of general forestry work, including the extraction of felled tree trunks from the depths of thick woods and their carriage on trailers along the highway to sawmills,

When one spends a day watching a team of two . men, or perhaps three, making use of up-to-date forestry equipment, one realizes that, before such equipment became available, much work of this kind simply could not be done at all. The extraction of whole butts of elm, oak or beech from English forests is extremely difficult work and often a team of 12 trained forest horses is incapable of shifting a large trunk, even so much as an inch. Many a valuable piece of timber is, for this reason, left to rot. In the past steam tractors have sometimes come to the aid of horses, but their great weight precludes altogether the possibility of utilizing them in soft ground far away from the road. Sleepers may be laid to make a firm track for them, but, naturally, there are limitations to this practice.

It will be realized that, for the purpose of shifting even two or•three heavy tree trunks, it might be necessary to bring a team of a dozen horses with their men 30 or 40 miles, and this would involve_stabling them for the night; even then, disappointment might attend their efforts to extract a deep-laid and heavy butt.

Occasions have presented themselves from time to time for reporting in this journal upon work done by forestry tractors, and it may be recalled that, in our isSue dated July 7th, 1931, we publisheda road-test article describing three days' work with a Lath l KTL B32 tractor, including one day spent in the beet fields of Norfolk, a day on forestry work in Berkshire, and a day on trunk-road haulage.

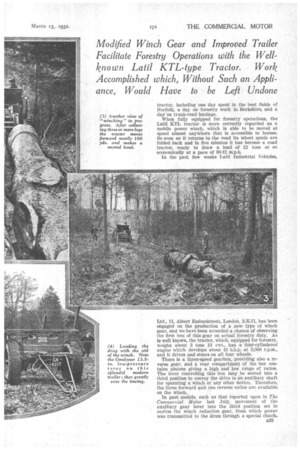

When fully equipped for forestry operations, the Latil KTL tractor is more correctly regarded as a mobile power winch, which is able to be moved at speed almost anywhere that is accessible to horses. So soon as it returns to the road its wheel spuds are folded back and in five minutes it has become a road tractor, ready to draw a load of 12 tons or so economically at a pace of 10-12 m.p.h.

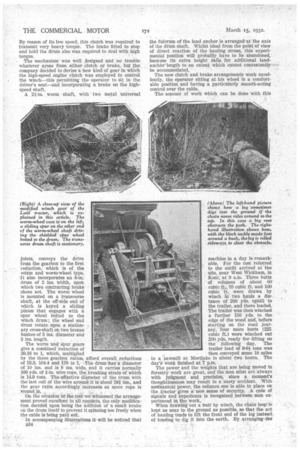

In the past few weeks Latil Industrial Vehicles, Ltd., 11, Albert Embankment, London, S.E.11, has been engaged on the production of a new type of winch gear, and we have been accorded a chance of observing the first test of this gear on actual forestry duty. As is well known, the tractor, which, equipped for forestry, weighs about 3 tons 13 cwt., has a four-cylindered engine which develops about 42 b.h.p. at 2,000 r.p.m., and it drives and steers on all four wheels.

There is a three-speed gearbox, providing also a reverse gear, and a rear compartment of the box contains pinions giving a high and low range of ratios. The lever controlling this box may be moved into a third position to convey the drive to an auxiliary shaft for operating a winch • or any other device.. Therefore, the three forward and one reverse ratios are available on the winch.

In past models, such as that reported upon in The Commercial Motor last July, movement of the auxiliary gear lever into the third position set in motion the winch reduction gear, from which power was transmitted to the drum through a special clutch.

By reason of its low speed, this clutch was required to transmit very heavy torque. The brake fitted to stop and hold the drum also was required to deal with high torque.

The mechanism was well designed and no trouble whatever arose from either clutch or brake, but the company decided to devise a new kind of gear in which the high-speed engine clutch was employed to control the winch—this permitting the operator to sit in the driver's seat—and incorporating a brake on the highspeed shaft.

A worm shaft, with two metal universal joints, conveys the drive from the gearbox to the first reduction, which is of the worm and worm-wheel type. -It also incorporates an 8-in. drum of 2 ins, width, upon which two contracting brake shoes act. The worm wheel is mounted on a transverse shaft, at the off-side end of which is keyed a sliding pinion that engages with a spur wheel bolted to the winch drum; the wheel and drum rotate upon a stationary cross-shaft on two bronze bushes of 3 ins, diameter and 3 ins. length.

The worm and spur gears give a combined reduction of 39.18 to 1, which, multiplied by the three gearbox ratios, afford overall reductions of 53.3, 104.4 and 178 to 1. The drum has a diameter of 10 ins, and is 8 ins, wide, and it carries normally 100 yds. of I-in. wire rope, the breaking strain of which is 14.9 tons. The effective diameter of the drum with the last coil of the wire around it is about 19iins., and the gear ratio accordingly increases as more rope is wound in.

• On the occasion of the test we 'witnessed the arrangement proved excellent in all respects, the only modification decideil upon being the addition of a small brake on the drum itself to prevent it spinning too freely when tbe cable is being paid out.

In accompanying illustrations it will be noticed that B34 the fulcrum of the land anchor is arranged at the axis of the drum shaft. Whilst ideal from the point of view of direct reaction of the hauling stress, this experimental position will probably have to be abandoned, because its extra height calls for additional landanchor length to an extent which cannot conveniently be accommodated.

The new clutch and brake arrangements work excellently, the operator sitting at his wheel in a comfortable position and having a particularly smooth-acting control over the cable.

The amount of work which can be done with this

machine in a day is remarkable. For the test referred to the outfit arrived at the site, near West Wickham, in Kent, at 9 a.m. Three butts of volumes of about 60, cubic ft., 70 cubic ft. and 100 cubic ft. were drawn by winch in two hauls a distance of 200 yds. uphill to the trailer, and there loaded. The trailer was then winched a further 150 yds. to the edge of the wood and, before starting on the road journey, four more butts (225 cubic ft.) were winched out 200 yds. ready for lifting on the following day. The trailer load of 9-9i tons was then conveyed some 18 miles to a, 'sawmill at Mortlake in about two hours. The day's work finished at 7 p.m. The power and the weights that are being moved in forestry work are great, and the men must act always with judgment and precision, since a moment's thoughtlessness may result in a nasty accident. With mechanical power, the reliance one is able to place on the tractor gives a new sense of security. A code of signals and expedients is recognized between men experienced in the work.

When drawing out a butt by winch, the chain loop is kept as near to the ground as possible, so that the act of hauling tends to lift the front end of the log instead. oftending to dig it into the earth. By arranging the chain loop at one side, the log can be made to roll laterally :a. few feet, while it is being hauled. , If, despite this, a standing tree is in the path, a round stick can often be used to fend off the moving butt. Should this expedient prove ineffective, a side pull can be taken through block tackle.

A heavy log will often move with surprising ease through an apparently impassable undergrowth of elderberry bushes, etc., and yet will be stopped dead by a piece of protruding root. Only straight hauls can be taken by the winch, and this explains the need for making two hauls almost at right angles to shift the three logs referred to a distance of 200 yds.

Loading on to the trailer by means of larch skids and a long chain loop is accomplished with remarkable ease, and an advantage is found with the latest Latil. timber drag (which has Goodyear 13.5-in, low-pressure tyres) in that it can be taken into softer ground than could the earlier models having twin high-pressure tyres, also it ploughs more easily through heavy .going. In the worst of conditions, it can always be extricated.

Leaving the estate necessitated taking the drag, with its 35-ft. load, through an 11-ft. gateway on to a 144t. road, including turning at. right-angles. This seemingly impossible task was accomplished without hesitancy by means of the winch, the trailer forecarriage being turned by hitching the -wire rope on to one of the side hooks, instead of on to the drawbar.

The final stage of the journey, by road, gives a last emphasis to the usefulness of the Latil outfit. An average speed of about 10 m.p.h. is maintained with safety, the range of six gears proving invaluable, whilst braking is effected with the aid of a Westinghouse vacuum system comprising two 0-in. cylinders on the drag and an autora. atic vacuura, reiervoit' on the tractor. A Neate trailer-brake gear also is provided.