A CONVERSKY

Page 44

Page 45

Page 46

If you've noticed an error in this article please click here to report it so we can fix it.

SIX-WHEELER

Performs Well

The Successful Flexion Balancer-arm Conver.

sion Principle Applied to the Popular Bedford Chassis. Good Results

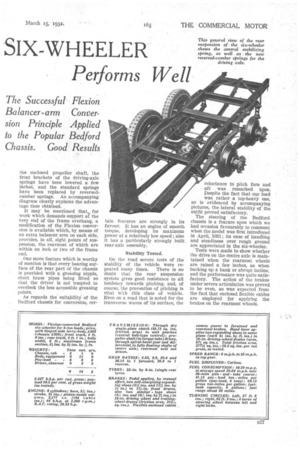

AWELL-TRIED example of conversion system for turning the orthodox four-wheeled chassis into a rigid six-wheeler of the trailing-axle type is the Flexion outfit, marketed by Flexion Products, Ltd., The Hyde, Hendon, London, N.W.9. It has frequently been referred to in this journal, and we have now subjected a converted Bedford chassis, intended to carry a useful pay-load of four tons, to our standard form of road test.

At the outset it should be mentioned that the Flexion system was patented several years ago, and has been successfully applied to many kinds of chassis, heavy and light. One of its main features is that it affords the rear end of the frame three points of suspension at each side, so that, despite the necessity of keeping the two rear axles close together, the load is well distributed. Proportionate dimensions of the balancer arms, etc., are arranged so as to impose about 60 per cent, of the weight carried by the rear axles on to the driving axle and the remaining 40 per cent, on to the trailing axle.

Since the Flexion conversion was taken overr by Flexion Products, Ltd., some modifications have been introduced in both the design and the method of construction. A 3k-in. nickel-chrome-steel tube is employed for the trailing axle, the springs being mounted beneath it by means of spherical bearings, which relieve them of twisting stress when the wheels on one side rise. The frameextension channels are bolted over the main frame members, the latter not being cut.

Improvements in Construction.

Webbed castings are now employed for the front-end brackets of the rearmost springs. The balance beams also now take the form of flanged castings, and the cast shackles have been redesigned. The bushes and shacklepins throughout are standard Bedford parts, also the

trailing axle carries Bedford hubs, wheels and brake assembly. The rubbing plates on the main balancer arms are of case-hardened steel and have lubricating points.

Late in 1931 a modification was introduced in the form of a fourleaf spring fixed to a saddle above the trailing axle, its ends pressing against flanged rubbing plates on the rear frame cross-member and on the cross-tube which connects the front ends of the rear springs. This is claimed to give increased steadiness, particularly in the lateral direction, and is especially appreciated when running light.

In regard to the Bedford outfit, another alteration has just been effected. In order to make the arc of the driving axle conform more nearly to the arc struck from the centre of the front universal joint of

the enclosed propeller shaft, the front brackets of the driving-axle springs have been lowered a few inches, and the standard springs have been replaced by reversedcamber springs. An accompanying diagram clearly explains the advantage thus obtained.

It may be mentioned that, for work which demands support at the very end of the frame overhang, a modification of the Flexion conversion is available which, by means of an extra balancer arm on each side, provides, in all, eight points of suspension, the rearmost of which are within an inch or two of the frame end.

One more feature which is worthy of mention is that every bearing surface of the rear part of the chassis is provided with a greasing short brass pipes being fitted so that the driver is not tempted to overlook the less accessible greasing points.

As regards the suitability of the Bedford chassis for conversion, cer Lain features are strongly in its favour. It has an engine of smooth torque, developing its maximum power at a relatively low speed ; also It has a particularly strongly built rear-axle assembly.

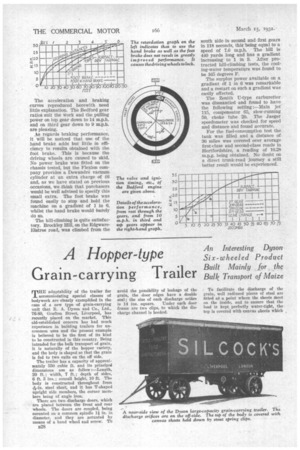

Stability Tested: On the road severe tests of the stability of the vehicle were repeated many times. There is no doubt that the rear suspension system gives good resistance to all tendency towards pitching, and, of course, the prevention of pitching is vital with this class of vehicle. Even on a road that is noted for the transverse waves of its surface, the reluctance to .pitch fore and aft was remarked upon. Despite the fact that our load was rather a top-heavy one, as is evidenced by accompanying pictures, the lateral stability of the outfit proved satisfactory.

The steering of the Bedford chassis is a feature upon which we had occasion favourably to comment when the model was first introduced in April, 1931; its ease of handling and steadiness over rough ground are appreciated in the six-wheeler.

Tests were made to show whether the drive on the centre axle is maintained when the rearmost wheels are raised a few inches, as when backing up a bank or abrupt incline, and the performance was quite satisfactory. The action of the brakes under severe articulation was proved to be even, as was expected from the fact. that enclosed flexible cables are employed for applying the brakes on the rearmost wheels. The acceleration and braking curves reproduced herewith need little explanation. The Bedford gear ratios suit the work and the pulling power on top gear down to 14 m.p.h. and on third gear down to 9 m.p.h. are pleasing.

..t.s regards braking performance, it will be noticed that use of the hand brake adds but little in efficiency to results obtained with the foot brake. This is because the driving wheels are caused to skid. No power brake was fitted on the chassis tested, but the Flexion company provides a Dewandre vacuum cylinder at an extra charge of f6 and, as we have stated on previous occasions, we think that purchasers would be well advised to specify this small extra. The foot brake was found easily to stop and hold the machine on a gradient of 1 in 6, whilst the hand brake would barely do The hill-climbing is quite satisfactory. Brockley Hill, on the EdgwareElstree road, was climbed from the south side in second and first gears in 118 seconds, this being equal to a speed of 7.6 m.p.h. The hill is 440 yards long and has a gradient increasing to 1 in 9. After protracted hill-climbing tests, the cooling-water temperature was found to be 165 degrees F.

The surplus power available on a gradient dr 1 in 6 was remarkable and a restart on such a gradient was easily effected.

The Zenith U-type carburetter was dismantled and found to have the following setting :—Main jet 115, compensator 65, slow-running 50, choke tube 20. The Jaeger speedometer was checked for speed and distance and found accurate.

For the fuel-consumption test the tank was filled and a distance of 36 miles was covered over average first-class and second-class roads in Hertfordshire, a reading of 10.28 m.p.g. being obtained. No doubt on a direct trunk-road journey a still better result would be experienced.