REFUSE: ITS DISPOSAL AND FINANCE.

Page 35

Page 36

Page 37

Page 38

If you've noticed an error in this article please click here to report it so we can fix it.

How 40,000 Tons of London Refuse is Dealt with Economically, a Substantial Saving Following the Use of Power.

rriliE Metropolitan Borough of Hackney, situated in the extreme . north-east corner of the County of London, is the seventh largest of the boroughs in point of area and the sixth largest in point of population. Its area is 3,287 acres, and its population (at the last census) 222,142. It has a rateable value, ati disclosed at the last quinquennial valuation, of £1,417,495, and a rate of one penny in the £ produces £5,840. The rates haves been in the region of 16s. in the for some time. The work of the borough council has always had the reputation of being efficiently managed, whilst one of its enterprises, the electricity undertaking, ranks as one of the most profitable in the whole of the United Kingdom. The management here has been extremely efficient and methods of production have been adopted throughout the career of the undertaking which have always been reckoned to be ahead of the times.

The houserefuse collected in the borough is burnt in a 12-furnace destructor erected adjacent to the electric power house on the banks of the River Lea, and a credit of £3,000 per annum is transferred from the electricity undertaking to refuse-coliection accounts for the'heat which is received from the destructor, this heat representing a saving to the electricity undertaking of about one-tenth of its fuel.

Up to the end of the -financial year 1923-1024, the collection of the borough's refuse was put out to contract, and the figure representing the cost of col' lection which is comparable with the cost arrived at by the system adopted after the year 1924 was 12s. 7/d. per ton.

In the year 1921. it was decided to experiment with electric vehicles used for refuse collection, and four chassis were purchased from Ransomes, Sims, and :Tefferies, Ltd., these being two 3i-tonners and two 2-tonners, each with side-tipping bodies.

The estimate (admittedly on the eoneervative side) of Mr. Norman Scorgie, the borough engineer and surveyor, was that /2,000 per annum would be saved if the collection were done by the borough instead of being let out to contract and if electric vehicles were used in the operation. As the result of 18 months' experiment it was definitely proved that electric traction was more economical than horsed traction to the extent, on a full year's work, of about £4,000. The council, on this showing, decided to take up a loan for five years to purchase a fleet of vehicles, to erect a garage and to equip it with charging plant, machine tools and the necessary appliances.

The choice of chassis fell upon the Garrett 31-tonner, somewhat modified to suit the requirements of the borough. The first order placed for these was far 20 with the option to purchase three more at the same price. It was found that the three extra electric vehicles could he employed, and they were added to the fleet in the first financial year.

The garage was erected in 1924 from the designs of Mr. Grunspan, of Westminster. It was erected in ferroconcrete with a length of 200 ft. and a width of 60 ft, in a single span. The Maill piers are spafeed 15 ft. apart and are but 12ins, square in cross section_ They carry ferro-concrete roof girders upon which is erected a reinforced-concrete roof covered with two-ply rubberoid.• 'The walls between the piers are but 3 ins. thick, but so good is the design that this building, although of such light construction, is enormously strong. It is glaeed with patent glazing in the roof and has teel sashes in the walls. The floor is of reinforced concrete 6 ins. thick. The first 40 ft. or thereabouts by the entrance is taken up, on the one side, by offices and a boiler room and, oh the otherside, by the motor generator room and lavatories_ At the farther end of the garage a little • over 21 ft. of the length a the garage is taken up by an open workshop partially divided from the main building by a 4-in. wall. At one end of the workshop two inspection pits are constructed. The other end of the workshop is occupied -by machine tools, whilst the central portion has work benches against the wall, and this central space affords accommodation for parking two vehicles. The main floor of the garage will accommodate, along each side, nine vehicles, one to each pier and giving a width of 15 ft. to each vehicle, so that without encroaching upon the central gangway 20 vehicles are accom

modated ; the others, therefore, are at night-time placed along the centre.

'Axed to each pier is a charging panel, and another panel is fixed to each wall of the workshop, so that 20 vehicles can be charged at one time. Two of these panels are provided with long leads so that two vehicles requiring only a light charge are parked adjacent to each of these panels, and when one battery has been charged the plug is transferred to the battery of the other vehicle, so that altogether 22 vehicles can have their batteries recharged every night. We will deal with the question of charging later on:

The Garrett chassis with batteries each weighs 4 tons 12 cwt. The batteries in the case of 25 of the vehicles are the I.M.V.9 300-amp.-hour Extee made by the Chloride Electrical Storage Co., Ltd., of Manchester. One vehicle is equipped with a D.P. • battery, and with a' battery, At the end of three years, which is taken as .the life of a battery, it wiff be possible to make comparisons.

The 2-ton Ransomes chassis have been fitted with low-sided platform bodies and are used in connection with the work of the highwaydepartment,thus leaving 25 -vehicles which, in winter, are all used for refuse collection, whilst, in summer, silt of these vehicles are converted to watering and, normally, 18 are then used for refuse collection, one vehicle being kept in reserve. To ensure that all batteries shall be kept in good order,. however, the reserve vehicle stands idle for a fortnight only and is then put into service and another takes its place in reserve.

• The tipping bodies employed on these vehicles are somewhat unique and were designed by RanSomes and Rapier, Ltd., of 82, Victoria Street, London, S.W.1, specially for the Hackney Borough Council. The system is, therefore, quite unique, but now that it has proved so successful it is sure to be adopted by other authorities which have to handle large quantities of refuse and other materials.

Each chassis is provided with two mild-steel removable tipping tubs, the tare weight of each being about 13 cwt. and the cubic capacity of each about

5 cubic yds., or, roughly, a combined capacity of 280 cubie ft., a load of refuse weighing approximately .31. tons. The tub is rectangular, but tasters inwards towards the bottom. Riveted to each side is a flanged circular casting with a slot at the bottom.

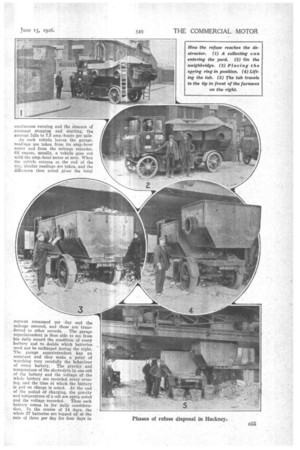

When the loaded vehicle reaches the destructor plant it is run, first of, all, on to a weighbridge, at the entrance to the depot and the weight of its load recorded ; it is then, taken under one. of tin three'electrictransformer cranes in t.eappitys platform shed, which .stands

in front of destructor furnaces. The crasiss run upon two lines on rails, one .of watch is flied to a gantry and the columns on the discharging side, and the other along the roadway against the outside wall of the tipping platform shed. Dependent from the cranes are two cables each of which terminates in a spring ring with a tongue. The rings are offered to the flanged bosses on the tub, the tongue in the interior face of a ring engaging with the slot on the flanged boss. When the lift is taken by

the crane the spring rings grip the flanged bosses tightly, and the tub is then lifted off the chassis. It is not secured to the Chassis in any way, but is merely pfkitioued by crosswise baulks and by four clips which straddle the chassis frame, the tub being lifted clear of the chassis and run directly• over to the pit in front of the furnace.

Having reached this position, the cable secured to each of the spring rings is rotated, thus rotating the tub, turning it upside down and emptying it on to the refuse hea.p. The tub, being emptied, is reversed and returned to the chassis. We timed the removal of the containers of one of these refuse-collecting vans, their emptying and return to position, and we found that the complete operation was effected in 2 mins: The way in which the fleet is operated IS thus. The vans all work in pairs and each pair of vans has its definite route to be covered during the day. At 7.30 in the morning, half of the fleet goes out, each vehicle being one of a pair and going off to its own set route, and taking with it a driver and four other fillers (because the driver also acts as a filler). At 8 o'clock the remainder

of the fleet goes out, each van to a certain predetermined place on its route where, it will meet its fellew van. By this time the first van with its four fillers working, will be nearly full. The load will be completed, and the full van will then be driven off with the driver this tithe the first van, with its four fillerswill transfer their attention to the second van and willL,set to work. collecting:refuse and loading it. By the One it is full the other van. will have returned from the tip ; so that the squad for two vans consists of two drivers and four fillers. Each van will, in this way, collect about three loads per-slay, and the total quantity of refuse handled per day in summer is about 120 tons, and in winter the average will be 200 tons with about 220 tons as the peak point. The daily collecting system sers-cs..betwoen 7,000 and 7,500 habitations, and the total quantity of refuse removed per year in the borough is 40,000 tons. As a result of the strike, when the furnace men ceased work, there was a very big accumulation of refuse in the borough, but the whole of that leeway has iltEW been worked off ; it has involved the collection of a record amount of about 224 tons per day.

The furnace men work in three shifts of eight hours, from 6 o'clock on Mon day morning to 6 o'clock. on the following Sunday morning, the shifts being from 6 a.m. to 2 p.m., from 2 p.m. to 10 p.m., and from 10 p.m. to 6 am. By Monday morning the flues have cooled sufficiently to permit of cleaning, and the furnaces are then relighted ready for the first loads which come in soon after 8 o'clock.

It is interesting to see the pickers at work on the refuse as it is dumped from the collecting vans. These men pay so much for the privilege of picking over the heap and taking out rag, glass, and nonsferrous metals and-anything else of

value' to to them. A second. contractor takes the whole r..)1 the tins and old iron.

The 12 furnaces employesl -are quite sufficient to deal 'With the 'whole of the refuse forming the winter collection, and in summer four of them are shut down. It is curious that the winter refuse is nnueli more satisfactory to handle, largely because it contains so much unburnt coal, cinders, etc., whilst in the summer the refuse contains more green stuff and it is greater in bulk, whilst, again, the clinker obtained in winter is harder and mere valuable.

The water tanks: of which there are six, have a capacity of 750 gallons each. They are mounted on Wood chocks which are strapped to the chassis. Six chassis only are equipped for this conversion, and each has its own water tank, for perfect interchangeability has not been attempted. The ch'ange'over can be made in from three and a half hours to four hours.

The distance covered daily by the refuse-collection vans varies from 11 to 14 miles, although as many as 19 miles are frequently covered, but in street watering the distance covered in a day varies from about 35 to 45 miles.

The total amount of current which is consumed by a van in refuse collection is from 90 to 120 amp.-hours, and in watering work as much as 280 amp.hours. On an average, it is found that in refuse collection the consumption is from 8 to 10 amp-hours per 'nine, whilst in street watering, because of the almost continuous running and the absence of .constant stopping and starting, the amount falls to 7.5 amp.-hours per mile As each vehicle leaves the garage, readings are taken from its amp.-hour meter and from the mileage recorder. Of course, usually, a vehicle goes out with the amp.-hour meter at zero. When the vehicle returns at the end of the day, 'similar readings are taken, and the difference then noted gives the total current consumed per day and the mileage covered, and these are trans ferred to other records. The garage superintendent is thus able to see from his daily record the condition of every battery and to decide which batteries need not be recharged during the night. The garage superintendent has an assistant and they make a point of watching very carefully the behaviour of every battery. The gravity and temperature of the electrolyte in one cell of the battery and the voltage of the whole battery are recorded every evening. and the time at which the battery is put on charge is noted. At the end of the period of charging, the gravity and temperature of a cell are again noted and the voltage recorded. Thus each battery comes in for daily consideration_ In the course of 14 days, the whole 27 batteries are topped up at the rate of three per day for four days in

the week, only two being so treated on Friday and none at all on Saturday, and as each battery is topped it is given a long slow charge so as to equalize the condition of all the cells in the battery, and whilst this long slow charge is being given hourly readings are taken. Every month, however, a still more thorough examination is given, in that the voltage, the gravity of the electrolyte and the temperature reading of each individual cell in the battery are noted. It• is by means of this carefulness in inspection and in maintenance that the batteries are kept in such good condition. The oldest battery in use has now done nearly four years' work, and with a boost at midday it still does the work required of it on one of the 2-ton highway wagons. All the batteries are guaranteed by the manufacturers for two years, but it is expected that from three and a half to four years' work will be got out of them.

In the summer the watering wagons, covering such a long distance, will consume as much as 280 amp.-hours of current and the whole night is required for recharging the batteries. There is time no opportunity normally available for equalizing the cells, but an opportunity is made in this way, that on the first wet day the Watering vans are taken in and then equalized, that is to say, they are given a full charge and then an over-charge over a period of four to six hours, and it is essential that this equalization charge should be given every foitnight.

Every day a reading is taken of the unit meters so as to ascertain the total amount of current taken from the power house. The daily consumption of current is about 650 units when the watering wagons are not in use, and about 900 units when they are in use. The hours of the two battery attendants are: number one, from 5 p.m. to 1 a.m.; number two, from 11 p.m. to 7 a.m., so that they always have two hours together, from 11 p.m. to 1 a.m., when the services of two might be required for heavy handling. On Saturday the working period is from 12 noon to 7 p.m. for both attendants. It is not the practice of the department to do any work at all on Sundays, and it is not considered good policy to have a spare battery, because of the difficulty of keeping any spare battery in proper condition.

The charging plant consists of a duplicate set of four transformers by the Lancashire Dynamo Co., these sets being run during alternate weeks. The current is received from the electricity undertaking at a pressure of 500 volts. This is divided into four circuits of 125 volts each, each circuit serving five panels. There is a supplementary charging plant, made by the Electric Construction Co., Ltd., which receives its current at 500 volts and at 72 amps. and delivers it at 110 volts and 250 amps. This is used for feeding one extra panel, so that, when necessary, the batteries of 23 vehicles can be charged.

The switchboards are by the Lancashire Dynamo Co. and by the Igranic Electric Co. In the motor generator room is an electrically heated still for producing the distilled water used for topping up the batteries., The Saturday task of the staff is to take one-half the fleet and to inspect and clean all controllers and motors, the controllers veing vaselined, so that the fleet is covered every fortnight.

The whole of the drivers have been trained by the department, and each day on returning to the garage, each driver fills up a card on which he reports any mechanical defect. These cards are at once examined by the garage superintendent and any work on a vehide,eonsidered necessary is at once put in hand.

The workshop plant consists of an 8-in. centre lathe and a 3i-in. centre lathe, both by Selson, a power hacksaw, a sensitive pillar drilling machine capable of drilling up to in.. an,ernery grinder with wet and dry wheels, benches with a bench press for pressing out bushes, and a portable forge, whilst a 3-ton travelling crane travels on overhead rails. The efficiency of this plant and of the workshop staff may be gauged from the fact that the 6-ton Leyland lorries in use by the electricity department for the removal of clinker have been entirely reconditioned in the workshop, and they can deal with all necessary work on the electric motors.

The figures in connection with the undertaking are, of course, extremely in teresting. The capital outlay on 27 vehicles, including the water-van bodies, was £23,200. The garage cost ±8,800. the charging plant, etc., £3,000. The land on which the garage is erected belongs to the borough council, having been bought 20 years ago, and, on a 60-year loan, the total charge against the garage accounts in connection with the land is only f14 per annum. The loan for the purchase of the vehicles, garage, etc., was obtained for a period of five years, and, therefore, will be paid off at the end of that period. The capital charges work out at about 3s. 84d. per ton of refuse on a basis of 40,000 tons per annum : at the end of the five years, when the loan is paid off, this charge will cease. The cost for col

lection and everything to do with the running of the vehicles is set out in the appended analysis of cost and comes to Is. 30. per ton; so that the total cost, including all capital charges, works out at eleven shillings and a fraction of a penny per ton, showing a saving of over is. 7d. per ton as compared with horse traction through a contractor. From a transport point of view, the figure would be less because the wages of the fillers and of the driver-filler should be charged to refuse collection, and not to transport. The amount so deducted should roughly-1e 3s. 6c1. per ton, thus reducing the transport costs, including capital charges on vehicles and garage, to 7s. ad. per ton_ When the capital charges cease the figure will fall to about 3s. 9id. per ton, which sum, it will be noticed, includes 1s. 0.95d. per ton appropriated to the reserve account for the renewal of batteries and tyres, for by the time the batteries are due for replacement the sum of about £6,000 will be available for the purpose.

When horse transport was employed the contract figure comparable with this was 12s. 7.25d.

The accounts for the year ended March 31st, 1926, are expected to show a slightly better result.