For DRIVERS, MECHANICS Si FOREMEN.

Page 27

If you've noticed an error in this article please click here to report it so we can fix it.

TEN SHILLINGS is paid to the sender of any letter which we publish on this page, and an EXTRA FIVE SHILLINGS to the sender of the one which we select as being the best each week. All notes are edited before being published. Mention your employer's name, in confidence, as evidence of good faith. Address, D., M. and F., "The Commercial Motor," 7-16, Rosebery Avenue, London, E.C. 1.

Lamps Alight.

On Saturday, June 19th, light your lamps at 9.49 in London, 10.29 in Edinburgh, 10.17 in Newcastle, 10.12 in Liverpool, 10.2 in Birmingham, 9.59 in Bristol, and 10.55 in Dublin.

A Connecting Rod Boring Jig.

The sender of the following communication has been awarded the extra payment of 5s. this week.

[2,1001 " A.L." (London, W. 11) writes :— " For quite a long time I was in a shop which possessed as its equipment little more than one lathe, and that of 6 in. centres, without a gap. This machine, it will readily be realized, had its limits as regards the work which it could be called anon to do; and, amongst other things, it was not much use for reboring connecting rod big-ends, a class of work which frequently comes the way of therepairer. I had therefore to rig up something which would serve as a machine to enable me to do such jobs, and as.

there are no doubt many readers who are similarly placed as regards equipment, a description of the fitting which I made will no doubt be of interest.

"In a couple of plates, shown clearly in the sketch which accompanies this letter [We have had it redrawn.—En.], I mounted a boring bar. In one plate the liar was a running-fit, but in the other I fitted a bush (A), which was held from revolving' by the setscrew C. The boring bar was threaded, as shown, for la portion of its length, the thread being a fairly fine one, as it,had to serve as a Med screw. The bush (A) was threadedinternally to accommodate the bar, and a nut was provided below the bush as well as another above the plate (B). The tap of the bar was squared so that it could be tiirned•by hand, using a suitable spanner. The connecthig rod was held in the usual manner on the lowerrplate, with suitable packing pieces, and for convenience the same bolts were used to secure it in place as also connected the two main plates of the "No explanation of the working of the tool is required : thwrsketch is self-explanatory. When the ends of the bearing have to be rounded, a suitable tool is. inserted in the boring bar, and the setscrew (C) released so that the automatic feed ceases to operate. The tool is fed 46ip to its work by suitable manipulation of the two nuts shown, one above and the other below the upper plate (B)."

Amateur Gear Cutting.

(2 toij " J.M." (Blidifax) writes :—" The following. story, although not directly Concerning a commercial motor vehicle, will, I am sure, be of general interest to the readers of your 'DAL and F.' page. A friend' of mine had trouble with his motor-bicycle and sidecar. The trouble was evidently in the gearbox somewhere, and, on. taking that part of the machine to pieces, we found that one of the gearwheels was badly damaged, to such an extent, indeed, that a new wheel was absolutely necessary. Spare .parts were at that time -unobtainable, and I offered to have'a shot at doing the job myself.

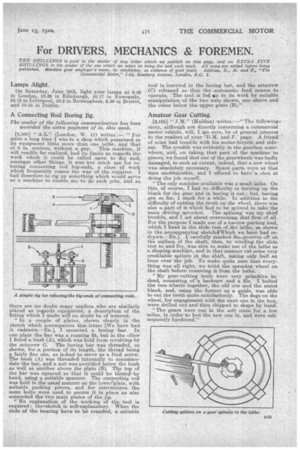

"The only machine available was a small lathe. On this, of course, I had no difficulty in turning up the blank for the gear and in boring it out ; but, having got so far, I stuck for a while. In addition to the difficulty of cutting the teeth on the wheel, there was also a part of it which had to be splined to take the main driving sprocket. The splining" was my chief trouble, and I set about overcoming that first. of all. For the purpose I made use of a narrow parting tool, which I fixed in the slide rest of,the lathe, as shown in the accompanying sketchi[Which we have had redrawn.—En.]. I carefully marked the.,grooves off on the surface of the shaft, then, by winding the slide rest to and fro, was able to make use of the lathe as a shaping machine, and in that manner cut some very creditable -splines in the shaft, taking only half an hour over the job. To make quite sure that everything was all right, we tried the sprocket wheel on the shaft before removing it from the lathe.

"My gear-cutting tools were very primitive indeed, consisting of 'a hacksaw and a file. I bolted the two wheels together, the old one and the uncut blank, and, using the former as a guile, was able to cut the teeth' quite satisfactorily. The dogs on the wheel, for engagement with the next one in the box, were drilled out and then chipped to shape by hand.

"The gears were run in the soft state for a few miles, in order to bed the new one in, and were subsequently hardened."