Suspension Marks Time

Page 70

Page 71

Page 72

If you've noticed an error in this article please click here to report it so we can fix it.

By P. A. C. Brockhigton,

A.M.I.Mech.E. WHAT is the future of air suspension? Nearly every manufacturer and vehicle user in the country has appraised its merits in relationship to the type of vehicle he produces or operates. The general policy is to wait and see.

Cost factors are multiple and complicated, and are the most common deterrent to its immediate adoption. Demand stimulates greater demand and reduces costs.

On the production side, the ease with which the suspension can be installed as optional equipment may, initially, be more important than first cost, but it may open up possibilities of giving a cheap vehicle the performance of a much more costly conventional type.

Major Modifications

Allied to this concept is the ability of air suspension to eliminate the need to modify springs to suit individual requirements and varying load capaci ties in standard vehicles. With the increasing use of specialized loadcarrying techniques based on standard types of chassis, the difference between the heaviest and the _lightest loads carried is also increased, and many operators are faced with major spring modifications, or the use of a special chassis, to obtain suitable suspension characteristics.

Factual news that would put air suspension permanently on the map would be the publication of operational results showing that it had reduced overall running costs. According to technicians of the suspension division of the Dunlop Rubber Co., Ltd., Coventry, such results will be available in the not-too-distant future.

They emphasize that the Dunlop Pneuride system has been applied to a wide variety of chassis types for different objectives and that this spread of interest has highlighted many installation and operational advantages that were formerly obscure.

In the background, the development of the flexible beam type of suspen • sion, described exclusively in The Commercial Motor on April 1, has reduccd the cost of replacement units and facilitated fitting procedures, whilst the latest simplified levelling valve is designed to give freedom from maintenance over a long period.

Combining a bellows spring with rolling-lobe section also represents a means of widening the scope of standard units, and advances in the detail design of leaf-spring combined with air suspension r4resent another costsaving development.

Although an ambulance is normally regarded as a highly specialized type of vehicle, the satisfactory conversion of standard goods chassis for ambulance service by the application of air springing is a cost-saving project of general interest to many potential users.

In this case the vehicle gives a ride, laden and unladen, comparable with that provided by an expensive limousine chassis. The normal load often includes patients (in varying numbers) to whom comfort is essential, and their welfare on the road may be compared with freedom from damage of fragile goods on the outward journey of a goods vehicle and of lightly constructed bodywork on the return run with an empty vehicle.

Chassis conversions for ambulance work have mainly comprised the

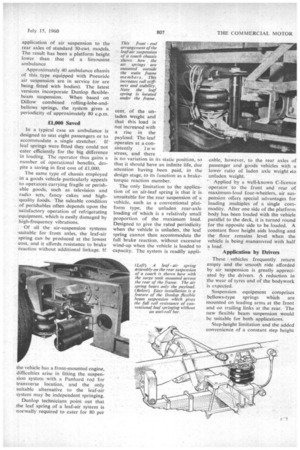

application of air suspension to the rear axles of standard 30-cwt. models. The result has been a platform height lower than that of a limousine ambulance Approximately 40 ambulance chassis of this type equipped with Pneuridc air suspension are in service (or are being fitted with bodies). The latest versions incorporate Dunlop flexiblebeam suspension. When based on Dillow combined rolling-lobe-andbellows springs, the system gives a periodicity of approximately 80 c.p.m.

£1,000 Saved In a typical case an ambulance is designed to seat eight passengers or to accommodate a single stretcher. If leaf springs were fitted they could not cater efficiently for the big difference in loading. The operator thus gains a number of operational benefits, despite a saving in first cost of £1,000.

The same type of chassis employed in a goods vehicle particularly appeals to operators carrying fragile or perishable goods, such as television and radio sets, fancy cakes and highquality foods. The saleable condition of perishables often depends upon the satisfactory operation of refrigerating equipment, which is easily damaged by high-frequency vibrations.

Of all the air-suspension systems .suitable for front axles, the leaf-air spring can be produced at the lowest cost, and it affords resistance to brake' reaction without additional linkage. If the vehicle has a front-mounted engine, difficulties arise in fitting the suspension system with a Panhard rod for transverse location, and the only suitable alternative to the leaf-air system may be independent springing.

Dunlop technicians point out that the leaf spring of a leaf-air system is normally required to cater for 80 per cent. of the unladen weight and that this load is not increased with a rise in the payload. The leaf operates at a con

sistently 1 o w stress, and there is no variation in its static position, so that it should have an infinite life, due attention having been paid, in the design stage, to its function as a braketorque reaction member.

The only limitation to the application of an air-leaf spring is that it is• unsuitable for the rear suspension of a vehicle, such as a conventional platform type, the unladen rear-axle loading of which is a relatively small proportion of the maximum load. Designed to give the rated periodicity when the vehicle is unladen, the leaf spring cannot then accommodate the full brake reaction, without excessive wind-up when the vehicle is loaded to capacity. The system is readily appli cable, however, to the rear axles of passenger and goods vehicles with a lower ratio of laden axle weight .to unladen weight.

Applied by a well-known C-licence operator to the front and rear of maximum-load four-wheelers, air suspension offers special advantages for loading multiples of a single commodity. After one side of the platform body has been loaded with the vehicle parallel to the deck, it is turned round for the opposite side to be loaded. A constant floor height aids loading and the floor remains level when the vehicle is being manceuvred with half a load.

Application by Drivers

These vehicles frequently return empty and the smooth ride afforded by air suspension is greatly appreciated by the drivers. A reduction in the wear of tyres and of the bodywork is expected.

Suspension equipment comprises bellows-type springs which are mounted on leading arms at the front and on trailing links at the rear. The new flexible beam suspension would be suitable for both applications.

Step-height limitation and the added convenience of a constant step height are outstanding advantages offered by air suspension for double-deckers. Well-known examples include a rearengined bus with a front entrance, the front axle of which is equipped with air suspension, and a front-engined rear-entrance bus with air suspension at the rear.

A leaf-air system is particularly suitable for the former, whilst the layout of the rear suspension depends upon details of chassis construction and so on. Fitting bellows air springs to the A.E.C. Bridgemaster rearentrance double-decker is comparatively simple, because the original suspension was designed for coil springs. The roll stiffness of the vehicle is increased by the use of independent coil front suspension.

Full Compensation In stage-carriage service it is normal for passengers to show a preference for the near-side seats; and the selflevelling characteristic of an airsuspension system compensates fully, or in part (depending upon whether it is fitted to one or both axles) for this disproportionate loading, the effect of which is generally increased by road camber. Air springing makes handling of the vehicle easier under these. conditions and reduces the wear of tyres and springs.

In one notable application to a crush-load export coach, the particular value of fitting air-leaf springs at the front and rear is the ability of the suspension to accommodate an excessive overload, up to 120 passengers being carried at peak periods. The prototype of this vehicle, empty, normally laden and overloaded, completed a 1,000-mile pave test at the Motor Industry Research Association's proving ground without damage to the chassis, running gear or body.

In the case of small buses, the B38 chassis units are commonly of the private-car type, with low-periodicity independent front suspension, and the use of air suspension for the rear axle approaches the ideal combination. Despite the relatively small number of passengers carried the ratio of laden weight to unladen weight is high. Because of the limited space available it is preferable to make provision for air suspension in the initial design.

To exploit fully the weight-saving advantage of air springing, it will be necessary to design the chassis and bodywork to match it.

The Guy-Carrimore experimental 4,000 gal.

frameless articulated spirit tanker, the exclu sive road-test report of which was published in The Commercial Motor on March 13, 1959, gives an idea of what can be achieved. Its fuel-consump tion was 11.6 m.p.g. at an average speed of 29 m.p.h., some 3 m.p.g. better than for a conventional outfit of the same capacity.

The rear axle of the Guy" Formidable motive unit and the single axle of the semi-trailer were equipped with Dunlop Pneuride rolling lobe diaphragm air springs, and because of the uniform periodicity of the suspension, laden and unladen, it was possible to employ thinner tank shell material, compared with a tank based on conventional springing, and to abolish the full-length longitudinal under-ribs. This provided a saving of about 14 tons and enabled 4,000 gal. of spirit to be carried on a single-axle semi-trailer.

A recent Dunlop development of particular interest to the users of articulated outfits is a special valve circuit that can be applied to air springs fitted to the rear axle of the tractor. It enables the static height of the frame to be reduced in preparation for coupling-up. This device could also be employed to adjust the rear frame height of a platform vehicle to the level of the loading deck, so long as an external stop were provided physically to limit the upward movement of the frame.

Comparable Advantages Air springing on rigid tankers and heavier types of van offers weightsaving advantages comparable with those provided by air suspension in the case of the frameless articulated outfit.

A van equipped with two or threetier load-carrying racks has to be structurally robust and generally returns empty. High-frequency vibrations when the van is empty are combined with severe bump stresses if the road surface is poor, and the structure is either excessively heavy or liable to damage. If the body (and, preferably, the chassis) were designed for air suspension, a very substantial weight saving would be possible.