Roomy, Lively and Handy

Page 40

Page 41

Page 42

Page 43

If you've noticed an error in this article please click here to report it so we can fix it.

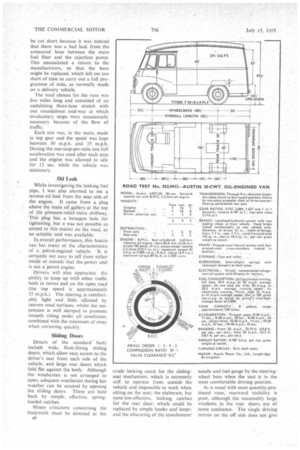

Powered by B.M .0 2.2-litre Oil Engine, New Austin 30-cwt. Van Does Well on Test: Capacity without Bulk Ensured by Forward Control By John F. Moon,

A.M.I.R.T.E. ALARGE payload space, a lively performance and a high degree of manceuvrability epitomize the new Austin 30-cwt. forward-control van. When powered by the B.M.C. 2.2-litre oil engine, these graces are further enhanced by a low fuel-consumption rate which does not detract from the general road performance.

The time-load-mileage facto!. of 3.090, which was produced from a continuous run under full load, is indicative of this economy, and during the tests several faultless starts were made on a 1-in-4 gradient, showing the van to lack nothing in power.

There are several advantages to be derived from the use of a forwardcontrol driving position in a vehicle of this sort. The driver has an excellent command of the roadway immediately in front of him, which is a great asset when continually pulling to the side of the road, as on delivery rounds. The wheelbase can be kept short without reducing the length of the goods compartment and this, in the case a the Austin, results in a turning circle of 36 ft.

The Austin 30-cwt. van is generally similar to the 1-ton vehicle, but differs principally in respect of heavier suspension, larger tyres, an increased brake-facing area and a lower rear-axle ratio.

Vans for the home market have a body of composite construction with a capacity of 275 cu. ft., whereas export vehicles have a 235-cu.-ft.

a6 body, which is identical to that used on the I-ton models. This smaller body has a sheet-metal roof, as opposed to the fabric one fitted to the 30-cwt. model, and is 6 in. shorter in the overhang.

The B.M.C. 2.2-litre oil engine, which was introduced Jut September, is an indirect-injection unit employing Ricardo Comet III combustion chambers. C.A.V. fuel-injection equipment is used throughout, with Ricardo Pintaux nozzles, and heater plugs are fitted as an aid to starting in cold weather.

The four-speed gearbox has constant-mesh gears on the third and top ratios but the presence of straightcut teeth on the other gear trains is betrayed by whine in the indirect ratios.

Iron weights totalling 30 cwt. were battened into the van body for the purpose of my test, and with a driver and passenger aboard the gross weight came to 3 tons 9-I cwt. I drove the vehicle from the Austin factory to Broadway and was immediately impressed with the quiet running of the power unit, although irritated by the direct mechanical operation of the starter, the lever of which was prone to jam, thus necessitating an uncomfortably hard push or, on one occasion, a kick.

I soon found that to get the best outof the engine it was necessary to treat it almost as a petrol unit. The torque peak occurs at 1,800 r.p.m. and although the curve is reasonably flat below that figure, it is necessary to keep the revolutions higher than one would expect with a compression-ignition unit.

Frequent use of the gearbox is called for, and for this reason I would like to see a synchromesh box as standard equipment. The gear change is not difficult, but the days of double de-clutching appear to be drawing to a close, certainty, on this class of vehicle.

Before tackling Fish Hill for temperature-rise and brake-fade checks. I took the Austin to Willersley Hill and at two points on this hill the Tapley meter showed the gradient to be 1 in 4. The hand brake held the van on these slopes. but the travel was rather excessive. An extremely smooth start was made in low gear without recourse to slipping the clutch, and this performance was repeated several times.

While climbing the lower slopes of this hill, I noticed rather bacl smoking from the exhaust, which became rAore pronounced as the engine speed dropped. I understand, however, that a slight tendency to smoking is a characteristic' of this unit and I have since noticed it on vehicles other than the test van.

Willersley Hill led to the top of Fish Hill, so I made a braking descent in top gear with the speed around the 20 m.p.h. mark. At the bottom of the hill an emergency stop from 20 m.p.h. produced a Tapley meter reading of 61 per cent. and at the conclusion of a second descent the meter registered 59 per cent. from the same speed.

This time there was a slight smell of hot facings, but no serious fade. The pedal movement had increased by ,1 in. and within a minute the brakes had regained their original effectiveness.

Good Climb in Second One ascent of Fish Hill was made in an ambient temperature of 65° F. and this produced a temperature rise of 300 F., the top tank .registering 184' F. at the end of the climb. Once past the lower slopes it was necessary to engage second gear, but a good climb was made in this ratio at the governed speed of the engine. which corresponded to a road specd of approximately 18 m.p.h.

The 1.1-mile climb, which has an average gradient of 1 in 14.2, with sections up to 1 in 10.5, was covered at an average speed of 15 m.p.h. No exhaust smoke was observed during this climb except when on the point of changing into a lower gear.

Acceleration and braking tests were conducted on my usual course in Solihull and the acceleration figures bear witness to the briskness of the vehicle.

Higb Fade Resistance If the braking performance was only average, this was because of the use of moulded facings which, as the tests on Fish Hill showed, have a very high resistance to fade. Despite the high pedal pressure needed to produce these figures, braking was generally adequate and the long life of these facings is sufficient recompense.

There was no wheel-locking and I had expected the rear wheels to skid —the normal tendency with this size of vehicle. As the weight-distribution figures show, however, -the rear-axle loading was high, each rear tyre being overloaded to the extent of 5 cwt., and this would help to produce increased braking distances.

The Coventry road between Sheldon and Meriden was used for the consumption tests, which had to be cut short because it was noticed that there was a bad leak from the armoured hose between the main fuel filter and the injection pump. This necessitated a -return to the manufacturers, so that the hose might be replaced, which left me too short of time to carry out a full programme of tests, as normally made on a delivery vehicle.

The road chosen for the runs was five miles long and consisted of an undulating three-lane stretch with one roundabout mid-way at which involuntary stops were occasionally necessary because of the flow of traffic.

Each test was, in the main, made in top gear and the speed was kept between 30 m.p.h. and 35 m.p.h. During the one-stop-per-mile test full acceleration was used after each stop and the engine was allowed to idle for 15 sec. while the vehicle was stationary.

Oil Leak

While investigating the leaking fuel pipe, I was also alarmed to see a serious oil leak from the near side of the engine. It came from a plug above the main oil gallery at the top of the pressure-relief-valve drillway. This plug has a hexagon hole fOr tightening, but it was not possible to attend to this Matter on the road, as no suitable tool was available.

In overall performance, this Austin van has many of the characteristics of a petrol-engined vehicle. It is certainly not easy to tell from either inside or outside that the-power unit is not a petrol engine.

Drivers will also appreciate the ability to keep up with other traffic both in towns and on the open road (the top speed is approximately 55 m.p.h.). The steering is comfortably light and little affected by uneven road surfaces, whilst the suspension is well damped to promote smooth riding under all conditions. combined with the minimum of sway when cornering quickly.

Sliding Doors Details of the standardbody include wide, flush-fitting sliding doors, which allow easy access to the driver's seat from each side of the vehicle, and large rear doors which fold flat against the body. Although the windscreen is not arranged to open, adequate ventilation during hot weather can be assured by opening the sliding doors. These are held back by simple. effective, springloaded catches.

Minor criticisms concerning the bodywork must be directed at the u8 crude locking catch for the slidingseat mechanism, which is extremely stiff to operate from outside the vehicle and impossible to work when sitting on the seat; the elaborate, but none-too-effective, locking catches for the rear door, which could be replaced by simple hooks and loops; and the obscuring of the speedometer needle and fuel gauge by the steeringwheel boss when the seat is in the most comfortable driving position.

As is usual with most quantity-produced vans; rearward visibility is poor, although the reasonably large windows in the rear doors are of some assistance. The single driving mirror on the off side does not give

a very clear view of the road behind, and visibility, to the near side is nil.

For my maintenance checks, I followed the tasks recommended in the service manual and found that few of these were possible with the standard tool kit. This tool kit consists essentially of a 1-in.-1'5-in. openended spanner, starting handle, mechanical jack, wheel-brace, grease gun, bleeder tube and a large ring spanner for dealing with the front hubs.

Checking the fuel, oil and water levels was easy and could be accomplished in under a minute. To lubricate the water-pump bearings would be a bit of a task, as the orifice is sealed by a cheese-headed screw well shrouded by bodywork and the main fuel filter. It may be possible to reach this screw with a very long screw-driver and to lubricate the bearings through a tube.

It was necessary to reach the fuellift pump from underneath the vehicle in order to remove the filter

for a heavy dumper. With twin 12.0024 tyres at the rear and single 44.00-20 front tyres, the rated axle loadings arc 22,000 lb. and 7,000 lb. respectively.

The A.E.0 11.3-litre oil engine developing 150 b.h.p. at 1.800 r.p.m. gives a maximum tractive effort of 15,000 lb. The vehicle is capable of climbing a gradient of 1 in 2.9, and the minimum road speed at which full torque is mailable is 2.26 m.p.h. The rated maximum speed is 25 m.p.h.

A five-speed gearbox provides low. gear and reverse ratios of 6.6 to 1, and

gauze for cleaning. This operation, including the time taken to reassemble the pump, took three minutes. The job was done mainly by touch, because it was impossible to see the pump cover or the gauze from below.

There are two batteries. These are carried alongside the left-hand frame member and are reached for servicing through two traps in the floorboard. Checking the electrolite level of both batteries occupied two minutes.

The top of the engine cowl is secured by a budget lock and a spring clip, and when this section is removed, the top of the engine is well exposed for normal servicing. Components on the sides of the block can be reached only by removing the lower section of the cowl. Its detachment is complicated by the passage of engine stop control and the starter lever through the cowl.

I changed the off-side front wheel and the time taken-131 minutes—

ratios of 4.34 to 1 (second), 2.64 to 1 (third), 1.57 to 1 (fourth), top gear being direct. The final drive includes epicyclic hub reduction gears, and the overall ratio is 10.125 to 1.

The front I-section beam axle is mounted on semi-elliptic springs and the rear axle of the standard model is directly attached to the chassis, four small coil springs in tension being fitted to both sida of the axle. Semi-elliptic rear suspension is also available. Heavy-duty pressed-steel channel sections 12 in. deep are used for the main

included remu vat ui LUC spare wheel and re-stowing the changed wheel. A hinged flap at the rear of the body lifts up to give access to the spare wheel, but there is no provision for holding it up, and it hit me on the heid when I let go of it. The 18 grease nipples on the chassis can be re-charged in 31 minutes.

1 borrowed some additional tools and removed the oil filter in 11 minutes; replacement took 3 minutes. An Austin fitter adjusted the tappets in 29 minutes, the engine being turned over on the electric starter. To bleed the braking system took 61 minutes.

Adjusting the brakes is a lengthy business occupying three-quarters of an hour, because each wheel has to be removed to gain access to the adjusters through the brake drums. I can see no reason why holes cannot be provided in the wheels to obviate the necessity of their removal. The holes could be sealed if necessary, by rubber plugs.

chassis members and crosshearers, which are reinforced with special angle flitch plates above the rear axle. A frame based on 21-in. main members could be supplied.

Standard equipment includes direct-air-operated brakes for which air is supplied by a 15 cu. water-cooled compressor. An engineoil cooler built into the radiator is an optional extra. The gearbox power take-off is designed to transmit the full torque of the engine. The compressor is driven by a separate shaft from the rear of the gearbox.

Basically similar to the standard model, full-forward-control vehicles, with leftor right-hand steering, would be built to suit users' requirements with any of the alternative features mentioned. A hydraulic or air-pressure servo-steering system may be specified.