HINTS ON MAINTENANCE.

Page 26

If you've noticed an error in this article please click here to report it so we can fix it.

How to Get the Best out of a Vehicle, to Secure Reliability and to Avoid Trouble.

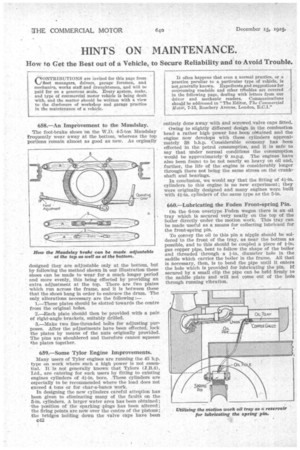

658.—An Improvement to the Maudslay.

The foot-brake shoes on the W.D. 4-5-ton Mendslay frequently wear away at the bottom, whereas the top portions remain almost as good as new. As orginally designed they are adjustable only at the bottom, but by following the method shown in our illustration these shoes can be made to wear for a much longer period and more evenly, this being effected by providing an extra adjustment at the top. There are two plates which run across the frame, and it is between these that the shoes hang in order to embrace the drum. The only alterations necessary are the following:— 1.—These plates should be slotted towards the centre from the original holes.

2.—Each plate should then be provided with a pair of right-angle brackets, suitably drilled.

3.—Make two fine-threaded bolts for adjusting purposes. After the adjustments have been effected, lock the plates by means of the nuts originally provided. The pins are shouldered and therefore cannot squeeze the plates together.

659.—Some Tylor Engine Improvements.

Many users of Tylor engines are running the 45 lip. type on work where such a high power is not essential. It is not generally known that Tylors (J.13.4), Ltd., are catering for such users by fitting to existing engines cylinders of 41-in, bore. These cylinders are especially to be recommended where the load does not exceed 4 tons or for char-a-bancs work.

In designing the new cylinders careful attecition has been given to eliminating many of the faults on the 5-in. cylinders. A larger water area has been obtained; -the position of the sparking plugs has been altered; the firing points are now over the centre of the pistons; the bridges holding down the valve caps have been

entirely done away with and screwed valve caps fitted.

Owing to slightly different design in the combustion head a rather high power has been obtained and the engine now develops with these cylinders approximately 38 b.h.p. Considerable economy has been effected in the petrol consumption, and it is safe to say that under normal conditions the consumption would be approximately 9 m.p.g. The engines have also been found to be not nearly so heavy on oil and, further, the life of the engine is considerably longer through there not being the same stress on the crankshaft and bearings.

In conclusion, we would say that the fitting of 41-in. cylinders to this engine is no new experiment; they were originally designed and many engines were built with 41-in, cylinders of the same type as the 5-in.

660.—Lubricating the Foden Front-spring Pin.

On the 6-ton overty-pe roden wagon there is an oil tray which is secured very neatly on the top of the boiler directly under the motion work. This tray can be made useful as a means for collecting lubricant for the front-spring pin.

To convey the oil to this pin a nipple should be soldered to the front of the tray, as near the bottom as possible, and to this should be coupled a piece of 1-in. gas copper pipe, bent to follow the shape of the boiler and threaded through a i-in, diameter hole in the saddle which carries the boiler in the frame. All that is necessary, then, is to bend the pipe until it enters the hole which is provided for lubricating the pin. If secured by a small clip the pipe can be held firmly to the saddle plate and will not come out of the hole through running vibration.