New Jen-Tug

Page 46

Page 47

Page 48

If you've noticed an error in this article please click here to report it so we can fix it.

Aare "Pull"

By

Laurence J. Cotton, M.I.R.T.E.

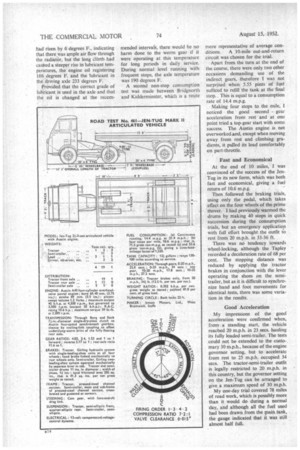

APART from its appearance, which is little changed, the JenTug Mark II articulated unit incorporates so many mechanical developments that it is virtually a new model. Its carrying capacity has been increased to 21-3-tons and better performance is obtained by employing the Austin A40 engine in conjunction with a four-speed synchromesh gearbox. There have been alterations in the position of the power and transmission units for load distribution and improved traction at the driving axle.

In the Ien-Tug, the engine, clutch, gearbox and final drive are mounted on a sub-frame in the chassis, so that should any component fail, the entire unit can be exchanged within an hour and the repair effected after the tractor is back in service.

Engine Governed The use of the Austin engine, clutch and gearbox has required a new sub-frame and the rear axle has been turned so that the final-drive housing is in alignment with the new position of the transmission. The engine is a standard A40 overheadvalve petrol unit, but equipped with a Lucas distributor governor which restricts the speed to 3,500 r.p.m. At this speed the corresponding output is 35 b.h.p. and 54 lb.-ft. torque. It is retained in the sub-frame through the usual Austin rubber-mounting arrangement, but two torque reaction buffers are added at the rear.

Both the clutch and gearbox are the same as the Austin car componentr and the selector gear is linked to the steering-column-lever by rods and levers.

The engine-transmission unit has been arranged nearer to the rear axle than before to improve traction, and in place of the conventional propeller shaft there is a Metalastik trailinglink coupling joining the gearbox output shaft and underslung worm drive nf the axle. Larger tyres, of eight ply rating, low-pressure type, are fitted to the driving axle, thus catering for the additional • load and improving adhesion. A differential unit is now standard, whereas before this was an optional fitting to the solid drive. •

Because the power unit has been moved back, the radiator has been re-positioned to provide more space between the fuel tank and the core, which is a four-row film unit with a pressure valve in the filler cap. A four-bladed fan is fitted, but provision is made for two blades to be detached for operation in cold weather.

As a precaution against dirt entering the engine, all air for combustion is drawn through a Burgess oil-bath cleaner, which has the inlet extended to the top of the cab, where a pre' cleaner is introduced. This arrangement prevents any of the dust-laden air between the wheels from being breathed by the engine, or the possibility of premature fouling of the oilbath cleaner.

The suspension has been improved

by the low-pressure tyres on the driving axle and the conventional Jeri,Tug arrangement of progressive sliding-end springs is retained. The same type of suspension is employed for the semi-trailer, which is strengthened for the additional load, and the rear axle moved 1 ft. nearer the tailbciard for correct weight distribution.

The cab now has steel panels,

because of the shortage of light-alloy material, and additional strength has been provided by employing gusset plates on the top and lower front. comer panels and a bracing plate between the door and rear corner

pillars, and wheel-arches. The bonnet top used to become damaged by loaders using it as a platform and provision has been made in the new design for an increase in thickness of the material, and an alteration in the shape and supports, to withstand heavier loads.

The standard electrical equipment for the tractor is a 12-volt dynamo, battery and starter, but as the prime mover may have to operate with semi-trailers having six-volt lighting, a resistance has been introduced into the circuit to the trailed unit to reduce the voltage to astandard.

My tests of the new len-Tug were started from the Jensen commercialvehicle works at Brierley Hill, near Dudley, where there was a rough unmade clinker track which tried the suspension. There were potholes, both shallow and deep, some causing the jockey wheels on the semi-trailer to touch down and spin as we drove along, but there was no wheel-spin on the driving axle either on level ground or when climbing stiff gradients.

The Tapley Meter was dislodged during the rough going, but I esti

mated that some of the inclines were about 1 in 8.

Because of the short wheelbase of the tractor, this was not a smooth trip, but much of the shock was absorbed by the low-pressure tyres and suspension, and the new Dunlopillo cushions in the cab made riding more comfortable.

Having subjected the outfit to a short off-the-road trial, I drove to the public weighbridge to find the total and distributed weights. The new position of the semi-trailer axle ensures that a greater proportion of the load is imposed on the rear of the tractor, thus improving adhesion.

The 1-ton weights used in the trials were evenly spaced and 11 tons (64.5 per cent.) of the total load on the tractor Was found to be carried on the driving axle. This is short, having track centres of 2 ft. 51 ins.

After a brief warming-up period, the fuel test tank was connected to the carburetter for consumption trials between Enville and Bridgnorth, a hilly route comparable with my standard electric-vehicle course at Watford. At the end of eight miles, the Jen-Tug was turned in one sweep in a 24-ft.-wide road, and a return Tun was made to the starting point.

The numerous gradients provided ample scope to practise gearchanging, which, with synchromesh engagement of second, third and fourth ratios, was simple. With the ignition governor in action there was backfiring in the silencer when overrunning the maximum controlled speed on declines, but this may act as a warning to the driver to keep the speed in check by using the brakes.

It took 524 mins. to cover the 16 miles, including turning, corresponding to an average speed of 18.4 m.p.h. and the fuel return worked out to 12.2 m.p.g., which, considering that the indirect gears were in use for 60 per cent, of the test, assessed by the time factor, is economical operation.

Up 1 in Eq After this, we headed towards Hermitage Hill at Bridgnorth, where the mile-long gradient has an average incline of 1 in 12 and the most severe section is 1 in 81. With a day temperature of 70 degrees F., the engineoil and water temperatures registered 148 degrees F. and 162 degrees F. respectively before starting the trial.

This was a lowand second-gear effort for the tractor and first gear was in use almost continuously for 41 mins. during the climb. With the radiator well clear of the fuel tank and rear panel, there was no increase in the cab temperature, and although it was a warm day I found no cause to complain of the ventilation arrangements.

A stop-start test was made' on the 1-in-81 section and as the outfit came to rest at the top of the hill, I made a hurried exit to take the running temperatures. The water temperature had risen by 6 degrees F., indicating that there was ample air flow through the radiator, but the long climb had caused a steeper rise in lubricant temperatures, the engine oil registering 186 degrees F. and the lubricant in the driving axle 233 degrees F.

Provided that the correct grade of lubricant is used in the axle and that the oil is changed at the recom

mended intervals, there would be no harm done to the worm gear if it were operating at this temperature for long periods in daily service. During normal level running with frequent stops, the axle temperature was 190 degrees F.

A second non-stop consumption test was made between Bridgnorth and Kidderminster, which is a route more representative of average con ditions. A 10-mile out-and-return circuit was chosen for the trial.

Apart from the turn at the end of the course, there were only two other occasions demanding use of the indirect gears, therefore I was not surprised when 535 pints of fuel sufficed to refill the tank at the final stop. This is equal to a consumption rate of 14.4 m.p.g.

Making four stops to the mile, I noticed the good second gear acceleration from rest and at one point tried a top-gear start with some success. The Austin engine is not overworked and, except when moving away from rest and climbing gradients, it pulled its load comfortably on part-throttle.

Fast and Economical

At the end of 10 miles, I was convinced of the success of the JenTug in its new form, which was both fast and economical, giving a fuel return of 10.6 m.p.g.

Then followed the braking trials, using only the pedal, which takes effect on the four wheels of the prime Mover. I had previously warmed the drums by making 40 stops in quick succession during the consumption trials, but an emergency application with full effort brought the outfit to rest from 20 m.p.h. in 33-36 ft.

There was no tendency towards wheel-locking, although the Tapley recorded a deceleration rate of 68 per cent. The stopping distance was reduced by applying the tractor brakes in conjunction with the lever operating the shoes on the semitrailer, but as it is difficult to synchronize hand and foot movements for identical tests, there was some variation in the results.

Good Acceleration

My impressions of the good acceleration were confirmed when, from a standing start, the vehicle reached 20 m.p.h. in 23 secs. hauling its fully loaded semi-trailer. The tests could not be extended to the custo-, mary 30 m.p.h., because of the engine governor setting, but to accelerate from rest to 25 m.p.h. occupied 34 secs. The tractor-semi-trailer outfit is legally restricted to 20 m.p.h. in this country, but the governor setting on the Jen-Tug can be arranged to give a maximum speed of 30 m.p.h.

My one-day trial covered 78 miles of road work, which is possibly more than it would do during a normal day, and although all the fuel used had been drawn from the ;min tank, the gauge indicated that it was still almost half full.