SIMPLE.

Page 74

If you've noticed an error in this article please click here to report it so we can fix it.

MEC:HIEN ICS

Locking devices

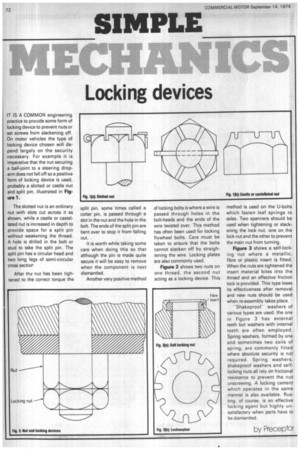

IT IS A COMMON engineering practice to provide some form of locking device to prevent nuts or set screws from slackening off. On motor vehicles the type of locking device chosen will depend largely on the security necessary. For example it is imperative that the nut securing a ball-joint to a steering droparm does not fall off so a positive form of locking device is used, probably a slotted or castle nut and split pin, illustrated in Figure 1.

The slotted nut is an ordinary nut with slots cut across it as shown, while a castle or castellated nut is increased in depth to provide space for a split pin without weakening the thread. A hole is drilled in the bolt or stud to take the split pin. The split pin has a circular head and two long legs of semi-circular cross section After the nut has been tightened to the correct torque the split pin, some times called a cotter pin, is passed through a slot in the nut and the hole in the bolt. The ends of the split pin are bent over to stop it from falling out.

It is worth while taking some care when doing this so that although the pin is made quite secure it will be easy to remove when the component is next dismantled.

Another very positive method of locking bolts is where a wire is passed through holes in the bolt-heads and the ends of the wire twisted over. This method has often been used for locking flywheel bolts. Care must be taken to ensure that the bolts cannot slacken off by straightening the wire. Locking plates are also commonly used.

Figure 2 shows two nuts on one thread, the second nut acting as a locking device. This method is used on the U-bolts which fasten leaf springs to axles. Two spanners should be used when tightening or slackening the lock nut, one on. the lock nut and the other to prevent the main nut from turning.

Figure 3 shows a self-locking nut where a metallic, fibre or plastic insert is fitted. When the nuts are tightened the insert material bites into the thread and an effective friction lock is provided. This type loses its effectiveness after removal and new nuts should be used when re-assembly takes place.

"Shakeproor washers of various types are used; the one in Figure 3 has external teeth but washers with internal teeth are often employed. Spring washers, formed by one and sometimes two coils of spring, are commonly fitted where absolute security is not required. Spring washers, shakeproof washers and selflocking nuts all rely on frictional resistance to prevent the nut unscrewing. A locking cement which operates in the same manner is also available. Rusting, of course, is an effective locking agent but highly unsatisfactory when parts have to be dismantled.

by Preceptor