Road-Rail Transport • An Unusual Scheme

Page 54

If you've noticed an error in this article please click here to report it so we can fix it.

CIA RAILWAY wagon having a detachable portion that can be used on the road as a trailer is described in patent No. 414,598 by J. R. L. Deglarge, 101, rue du Mont a Leux, Wattrelos, France, The chief feature is the arrangement of the trailer road wheels. These are constructed so that their axles can be swivelled through a right-angle and, as shown in the drawing, they are arranged in tandem for transport by rail. By this means the trailer can be run off the rail truck in a sideways direction, after which the road wheels are turned so that they lie in the normal running position, that is parallel with the trailer.

This invention permits a trailer to be removed from a train without lifting tackle, and without the need for the tractor having to back on to the rear of the train.

Using Tar Oils in Compression-ignition Engines.

INpatent No. 414,398 it is stated that the choice of fuel for compression-ignition. engines has hitherto been limited to that having a low selfignition temperature, such as gas. oil. Any attempt to use oils with a higher self-ignition point has produced "knocking," misfiring, and irregular running. A device to be inserted in the path of the injected fuel, in order to avoid these effects, is described in this patent by Gewerkschaft Mathias Stinnes, of Essen, Germany.

The drawing shows a cylinder head with the device (1) in position in the pre combustion chamber. It consists of a conical body suspended by thin arms, and its object is to retain heat from the combustion and transfer it to the incoming charge of fuel. The cone may be made either of metal or a metallic oxide, porous copper, porous nickel, and chrome-nickel steel being mentioned. , A further material is platbum, which, in addition to retaining the heat, acts also as a catalytic agent, enabling hydrocarbons to burn at a sub-normal temperature.

B44 Emergency Control of Power-assisted Brakes.

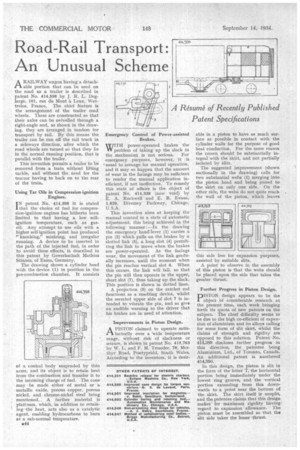

WITH power-operated brakes the VI' problem of taking up the slack in the mechanism is not serious. For emergency purposes, however, it is ousual to arrange for manual operation, and it may so happen that the amount of wear in the facings may be sufficient to render the manual application inefficient, if not ineffective. To remedy this state of affairs is the object of patent No, 414,338 (now void) by E. A. Rockwell • and E. R. Evans, 1,826, Diversey Parkway, Chicago U.S.A.

This invention aims at keeping the manual control in a state of automatic adjustment, this being achieved in the following manner:—In the drawing the emergency hand-lever (1) carries a pin (2) which pulls on the brakes by a slotted link (5), a long slot (4) permitting the link to move when the brakes are power-operated. As the facings wear, the movement of the link gradually increases, until the moment when the pin reaches vertical slot 6. When this occurs, the link will fall, so that the pin will then operate in the upper, short slot (7), thus taking up the slack. This position is shown in dotted lines.

A projection (3) on the ratchet rod functions as a resetting device, whilst the serrated upper side of slot 7 is intended to vibrate the pin, and so give an audible warning to the driver that his brakes are in need of attention.

Improvements in Piston Design.

APISTON claimed to operate satisfactorily over a 'wide temperature range, without risk of slackness or seizure, is shown in patent No. 413,763 by W. L. and F. M. Treseder, 76, Merthyr Road, Pontypridd, South Wales. According to the inventors, it is desir

able in a piston to have as much surface as possible in contact with the cylinder walls for the purpose of good heat conduction. For the same reason the crown should be substantially integral with the skirt, and not partially isolated by slits.

The suggested improvement (shown sectionally in the drawing) calls for two substantial webs (1) merging into the piston head and being joined to the skirt on only one side. On the other side, the webs do not quite reach the wall of the piston, which leaves this side free for expansion purposes, assisted by suitable slits.

A point to observe in the assembly of this piston is that the webs should be placed upon the side that takes the greater thrust.

Further Progress in Piston Design.

DISTON design appears to be the object bf considerable research at the present time, each week bringing forth its quota of new patents on the subject. The chief difficulty seems to be due to the high co-efficient of expansion of aluminium and its alloys calling for some form of slit skirt, whilst the claims of strength and rigidity are opposed to this solution. Patent. No. 414,389 discloses further progress in this direction, the patentee being Aluminium, Ltd., of Toronto, Canada. An additional patent is numbered 414,390.

In this design, the piston is slit in the form of the' letter' T; the horizontal portion being immediately under the lowest ring groove, and the vertical portion extending from this downwards to a point near the bottom of the skirt. The skirt itself is unsplit, and the patentee claims that this design makes for 'maximum rigidity having regard to expansion allowance. The piston must be assembled so that the slit side takes the lesser thrust.