CONTINENTAL D ;IGN APPROACHES BRITISH

Page 46

Page 47

Page 48

Page 50

If you've noticed an error in this article please click here to report it so we can fix it.

1ANDARDS THIS year the Paris Salon is being held in two parts. The first section, which closes to-morrow, is for cars and commercial-vehicle chassis. Complete vehicles will be on display from October 27November 6. The number of commercial-vehicle chassis at the current exhibition is disappointing, and Britain is represented only by Commer and Land-Rover vehicles. Other British goods chassis might have been on view, but for some peculiar reason the manufacturers failed to realize that commercial vehicles might be

shown. • This is the first time that many of the Continental machines have been displayed without bodywork, and it is apparent that cheap bodies have, in many cases, been hiding chassis of good design. A radical change has taken place in Continental design during the past year, and the finer details of British and Italian constrnction have been incorporated in the present_ models.

Competition Must be Watched

With the exception of the Citroen company, all other French manufacturers are able to point out new features in current design which, although not novel to their English contemporaries, show that Continental competition will have to be watched closely.

The French vehicle industry is already on its feet, and makers are quoting from one to eight months' delivery of cars to the domestic market, and from one to two months for export inquiries. Commercial chassis are available at a month's notice. This does not necessarily mean that the French export market is small, because every month the Renault concern alone sends 800 vehicles across the border into Belgium. The largest shipment of any British make of chassis to Belgium is 150 per month. '

French manufacturers are finding that devaluation of the i. has decreased their export potentialities in Europe in favour of British-made products, but they are of the opinion that this is only a temporary boost to the British industry and that soon the market will again swing in their favour.

Most of the light and medium ranges of goods chassis shown have been modified since last year and, whereas formerly frames were heavily constructed of inferior metal, they have now improved to the point where they almost compare with ours for strength and, lightness. Bolted frames are out of favour, and although most of the sideand cross-members are welded together, rivets are still used in some of the heavier machines.

Fabric universal-jointed couplings, which were found on almost every non-British machine at the 1948 Salon, have now almost disappeared, although they are still to be seen in Citroen prod bets. With the exception of the light front-wheel-drive model which has been added to the range, Citroen has remained unchanged since before the war. . .

The folly of complicated brake linkages and long, unsupported rods has been -realized, and this year's exhibits have been "cleaned up." British manufacturers should be flattered by the French imitations of their brake and transmission arrangements. Although foreign manufacturers were unwilling to admit plagiarism, comparison could readily be made with the Commer underfloor-engined chassis on display, which is representative of the latest British practice.

Wider Frames in the past, foreign makers have favoured narrow frames with the rear-suspension arrangement outside the side-members. With few exceptions, the present tendency is to employ a full-width frame and to mount the spring shackles directly under the side-members, where they are to some extent shielded from dirt and water. Helper-leaf arrangements are generally employed on goods and passenger vehicles, and shock absorbers are standard fittings on all commercial chassis.

Modifications , to the Renault suspension include a coil stabilizer spring, which is fitted in addition to the semi-elliptic leaf spring, and shock absorbers at all wheels. This coil stabilizer-spring arrangement is a Ciregoire patent and is offered as additional equipment on the Renault 1-tonner.

French gearbox design has improved. The size and weight of the main casting have been reduced, and most models are offered with constant-mesh gears on at least three ratios. Remote-control gearboxes are now giving way to combined engine-clutch-gearbox units.

Only three passenger chassis are shown. They are the Somua, Floriat and the Berliet. The Floriat and Berliet have been slightly modified, but even in their present forms they cannot be said to compare with the advanced design of such chassis as—to quote at random—the A.E.C., Daimler, Guy Arab or Leyland. All three models shown are of the 40-seater singledecker class, a feature of the Berliet being an offset spiral-bevel drive, of large proportions, to the rear axle The Floriat exhibit is equipped with a large electrical resistance brake, which is mounted amidships in the chassis. Fitted for use on long declines, it is said to produce a retarding force of 2 tons when the vehicle is travelling at 50 m.p.h. No details of its internal arrangements are available, but it has a malleable-iron casting and adds 31 cwt, to the weight of the chassis.

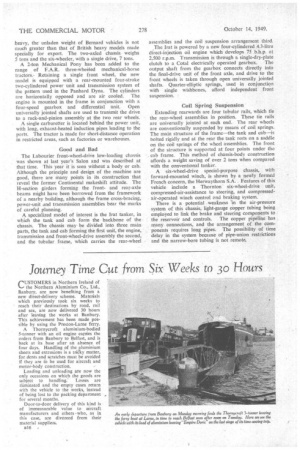

'A section of an integral body-chassis design wfth a horizontal engine beneath the floor is shown on the Renault stand. This concern has had prototype machines in operation in the Paris area for the past two years, and complete ehassisless vehicles are now being assembled at the rate of one a day; production, "The Commercial Motor" is informed, is to be stepped up to five a day within the next two months.

The horizontal power unit, a six-cylindered, directinjection oil engine, has a bore of 105 mm. and a stroke of 120 nun., giving a swept volume of 6.234 litres. Its maximum governed speed is 2,500 r.p.m., at which point it develops 105 b.h.p. The system used to promote turbulence at such high speed is not yet disclosed, but we are -informed that long, water-cooled injectors are fitted with nozzles having five holes of 0.001 in. diameter.

This engine has a shallow sump with the normal type of lubrication, and there is 141. ins, clearance between the drain plug and the road. Seven indium-bronze bearings of large surface area are employed to carry the crankshaft. The entire power unit, with clutch, weighs 121 cwt., and the five-speed gearbox, with Synchronizing arrangements for the four upper ratios, weighs 31 cwt. A single-plate clutch is fitted to the inter-urban vehicle, and a two-plate unit is supplied in town buses. The body is arranged for 45 seated and .five standing passen

a 14 gers, and the unladen weight of the new vehicle is 7+ tons A new semi-forward-control 7-ton chassis is shown by Berliet, the power unit being a.newly designed fivecylindered oil engine employing the Ricardo system of combustion. It has a bore of 120 ram., a stroke of 140 mm., and a swept volume of 7.9 litres. A power output of 110 b.h.p. is developed at 2,000 r.p.m. This vehicle is equipped with a five-speed overdrive-top gearbox positioned amidships in the frame, and a double-reduction drive to the rear axle. (Worm-driven axles are being superseded in Continental design by spiral-bevel and double-reduction gears.) Other details of this new chassis include a Westinghouse compressedair braking system, hydraulic shock absorbers in the front suspension, and helper leaves at the rear.

The Berliet and Bernard 1950 ranges of chassis retain the former long, narrow frames, and Bernard vehicles still have deep frames with cut-away sections to receive the rear axles. Although there has been an appreciable reduction in the length and number of brake rods on these vehicles, the Bernard system of an individual adjustable rod operating each shoe is still employed.

The manufacturer has planned for exceptional braking power, the new model having a compressed-air system with an hydraulic•master cylinder and operating units at all wheels. • The 10-ton two-axled chassis and 18-ton six-wheeler shown on the Bernard stand are equipped with a new engine. Two six-cylindered direct-injection engines are now being manufactured by the concern. An 8.55-litre 105 b.h.p. unit is fitted as standard, but a 12.1-litre 150 b.h.p. unit may be had as an alternative in the six-wheeler. Both engines develop their maximum power at 1,700 r.p.m. and have a common stroke of 152 mm. The bore of the smaller unit is 108 mm., and of the larger engine 130 nun.

.Earlier Bernard vehicles have been noted for the remote mounting of the gearbox and the lengthy open selector rods, but this arrangement has now been replaced by a five-speed constant-mesh gearbox mounted in conjunction with the engine and clutch.

Although the frames and components appear to be

heavy, the unladen weight of Bernard vehicles is not much greater than that of British heavy models made specially for export. The two-axled chassis weighs 5 tons and the six-wheeler, with a single drive, 7 tons.

A 2-ton Mechanical Pony has been added to the range of F.A.R. three-wheeled mechanical-horse tractors.Retaining a single front wheel, the new model is equipped with a rear-mounted four-stroke two-cylindered power unit and transmission system of the pattern used in the Panhard Dyna. The cylinders are horizontally opposed and are air cooled. The engine is mounted in the frame in conjunction with a four-speed gearbox and differential unit. Open universally jointed shafts are used to transmit the drive to a rack-and-pinion assembly at the two rear wheels.

A single carburetter is located behind the power unit, with long, exhaust-heated induction pipes leading to the ports. The tractor is made for short-distance operation in restricted areas, such as factories or warehouses.

Good and Bad The Labourier front-wheel-drive low-loading chassis was shown at last year's Salon and was described at that time. This year it is seen without a body or cab. Although the principle and design of the machine are good, there are many points in its construction that reveal the former Continental makeshift attitude. The H-section girders forming the frontand rear-axle beams might have been borrowed from the framework of a nearby building, although the frame cross-bracing, power-unit and transmission assemblies bear the marks of careful planning.

A specialized model of interest is the irat tanker, in which •the tank and cab form the backbone of the chassis. The chassis may be divided into three main parts, the tank and cab forming the first unit, the engine, transmission and front-wheel-drive assembly the second, and the tubular frame, which carries the rear-wheel

assemblies and the coil suspension arrangement third.

The kat is powered by a new four-cylindered 4.3-litre direct-injection oil engine which develops 75 b.h.p. at 2,500 r.p.m. Transmission is through a single-dry-plate clutch to a Cotal electrically operated gearbox. The output shaft from the gearbox connects directly into the final-drive unit of the front axle, and drive to the front wheels is taken through open universally jointed shafts. Quarter-elliptic springs, used in conjunction with single wishbones, afford independent front suspension.

Coil Spring Suspension Extending rearwards are four tubular rails, which tie the rear-wheel assemblies in position. These tie rails are universally jointed at each end. The rear wheels are conventionally suspended by means of coil springs. The main structure of the frame—the tank and cab—is bolted rigidly and at the rear the tank rests on a saddle on the coil springs of the wheel assemblies. The front of the structure is supported at four points under the cab frame. This method of chassis-body construction affords a weight saving of over 2 tons when compared with the conventional tanker.

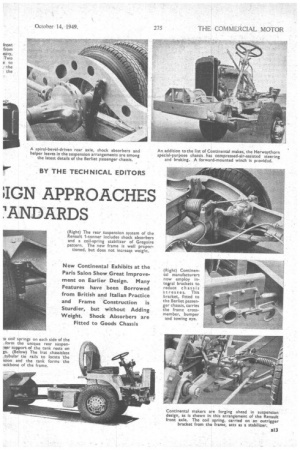

• A six-wheel-drive special-purpose chassis, with forward-mounted winch, is shown by a newly formed French concern, the Herwaythorn S.A.. Features of this vehicle include a Thornton six-wheel-drive unit, compressed-air-assistance to steering, and compressedair-operated winch control and braking system.

There is a potential weakness in the air-pressure system of this chassis, light-gauge copper tubing being employed to link the brake and steering components to the reservoir and controls. The copper pipeline has many connections, and the arrangement of the components requires long pipes. The possibility of time delay in the system because of pipe-union restrictions and the narrow-bore tubing is not remote,.