When a load of rubbish can cut costs

Page 77

Page 78

If you've noticed an error in this article please click here to report it so we can fix it.

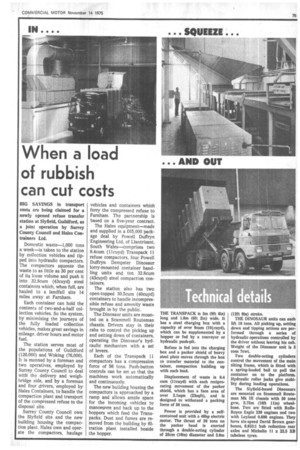

BIG SAVINGS in transport costs are being claimed for a newly opened refuse transfer station at Slyfield, Guildford, as a joint operation by Surrey County Council and Hales Contrainers Ltd.

Domestic waste-1,000 tons a week—is taken to the station by collection vehicles and tipped into hydraulic compactors. The compactors squeeze the waste to as little as 30 per cent of its loose volume and push it into 32.8cum (43cuyd) steel containers which, when full, are hauled to a landfall site 14 miles away at Farnham.

Each container can hold the contents of two-and-a-half collection vehicles. So the system, by minimising the journeys of the fully loaded collection vehicles, makes great savings in mileage, driver hours and motor fuel.

The station serves most of the populations of Guildford (120,000) and Woking (76,000). It is manned by a foreman and two operatives, employed by Surrey County Council to deal with the delivery and weighbridge side, and by a foreman and four drivers, employed by Hales Containers, to handle the compaction plant and transport of the compressed refuse to the disposal site.

Surrey County Council own the Slyfield site and the new building housing the compaction plant. Hales own and operate the compactors, haulage vehicles and containers which ferry the compressed refuse to Farnham. The partnership is based on a five-year contract.

The Hales equipment—made and supplied in a £65,000 package deal by Powell Duff ryn Engineering Ltd, of Llantrisant, South Wales—comprises two 8.4cum (11cuyd) Transpack 11 refuse compactors, four Powell Duff ryn Dempster Dinosaur lorry-mounted container handling units and ten 32 Scum (43cuyd) steel compaction containers.

The station also has two open-topped 30.5cum (40cuyd) containers to handle incompressible refuse and amenity waste brought in by the public.

The Dinosaur units are mounted on a Scammell Routeman chassis. Drivers stay in their cabs to control the picking up and setting down of containers, operating the Dinosaur's hydraulic mechanism with a set of levers.

Each of the Transpack 11 compactors has a compression force of 56 tons. Push-button controls can be set so that the machines work automatically and continuously.

The new building housing the compactors is approached by a ramp and allows ample space for the incoming vehicles to manoeuvre and back up to the hoppers which feed the Transpacks. Dust and fumes are removed from the building by filtration plant installed beside the hopper.

THE TRANSPACK is 3m (9ft 61n) long and 1.8m (61t 2in) wide. It has a steel charging box with a capacity of over 8cum (104cuyd), which can be supplemented by a hopper or fed by a conveyor or hydraulic push-pit.

Refuse is fed into the charging box and a packer shield of heavy steel plate moves through the box to transfer material to the container, compaction building up with each load.

Displacement of waste is 8.4 cum ,(11cuyd) with each reciprocating movement of the packer shield, which has a face area of over 2.1sqm (23sqft), and is designed to withstand a packing force of 56 tons.

Power is provided by a selfcontained unit with a 40hp electric motor. The thrust of 56 tons on the packer head is exerted through a double-acting cylinder of 25cm (1(Mn) diameter and 3.9m

(121t 91n) stroke.

THE DINOSAUR units can each lift .18 tons. All picking up, setting down and tipping actions are performed through a series of hydraulic operations controlled by the driver without leaving his cab. Weight of the Dinosaur unit is 3 tons 7cwt.

Two double-acting cylinders control the movement of the main tilting frame, which is fitted with a spring-loaded bail to pull the container on to the platform. Hydraulic roller jacks give stability during loading operations.

The Slyfield-based Dinosaurs are mounted on Scammell Routeman Mk III chassis with 30 tons gvw, 5.75m (18ft 1 lin) wheelbase. Two are fitted with RollsRoyce Eagle 220 engines and two with Leyland 0.680 engines. They have six-speed David Brown gearboxes, 6.933:1 hub reduction rear axles and Michelin 11 x 22.5 KB tubeless tyres.

Your recent article on trans. Sahara routes to Nigeria seems to have deterred some of the aspiring operators. However, we have had at least 200 inquiries recently, mainly from English hauliers, but also from the Continent, notably Holland, Germany and Spain, and about 15 per cent of these have consignments ready for delivery.

Although we thought the article gave a very accurate picture of the problems involved, we feel " difficult " rather than " impossible " should have been its theme; consequently some exporters and hauliers have developed cold feet over the idea of overland carriers. We say this not only for our vested interest, but because we feel something should be done about the country's balance of payments situation.

Exporters and hauliers alike seem to be unaware of our somewhat unique service, the essence of this being a commercial AA operation for traffic, (although we have would be geared to the Nigerian traffic, (Although we have parties interested in Sudan, Zaire and Republic Central Africa), our objective in this respect would be to form convoys of vehicles, a maximum of six units in Algeria and to lead them through the difficult and unfamiliar southern Sahara, through to Kano in Nigeria, some 1,200 miles.

The convoy will be escorted by one of six-wheel-drive trucks, specially modified for this type of operation, with extra fuel and water tanks, fitted with cranes and power winches to assist when vehicles in the convoy encounter problems with the terrain.

In addition, they will carry a range of tools and equipment, to give on-the-spot assistance to malfunctioning units, and a comprehensive medical chest for drivers.

The crews of the escort vehicles will be of proven experience and ingenuity; most will speak French, and will have had considerable experience operating heavy machinery under arduous conditions, therefore they will be available as relief drivers,