For DRIVERS, MECHANICS & FOREMEN.

Page 21

If you've noticed an error in this article please click here to report it so we can fix it.

A PRIZE OP '.1 EN SHILLINGS' is awarded each week to the sender of the best letter which we publish on this page ; all others are paid for at the rate of a penny a line, with an allowance for photograph:. Ail notes are edited before being published. Mention your employer's name, in confidence, as evidence of good faith. Address, D. Pl. and P., " The Commercial Motor," 7-16, Rosebery Avenue, London, E.G. 1.

Lamps Alight.

On Saturday, 16th November, light your lamps ti4 4.39 in London, 5.2 in Edinburgh, 4.30 in Newcastle, 4.43 in Liverpool, 4.42 in Birmingham, 4.49 in Bristol, and 5.32 in Dublin.

Remedying a Continental Engine Defect.

The sender of the following communication has been awarded the los. prize this week.

[1916] " H.R." (Stockton-on-Tees) writes :—" No doubt there are many thousands of lorries in this country fitted with the American Continental engine, which, whilst being a splendid piece of work and well designed in most respects, has one weak point, i.e., the method employed to Secure the gudgeon pin from moving laterally in the piston. The gudgeon pin on this engine, contrary to the usual American practice, is located in the piston, and by a single set-screw which passes through the gudgeon pin and piston boss, being screwed in the latter. The set-screw is prevented from unscrewing by means of a long split pin through its square head., the legs of the split pin are opened out horizontally, each leg being in contact with the inner wall of the Osten.

"So long as the split pin is horizontal the set-screw is locked, but if the split pin has been carelessly opened and its legs assume a vertical aspect, owing to its partial rotation, it no longer locks the screw, which is then free to unscrew and drop out, allowing the gudgeon pin to move endwise with results detrimental to the cylinder bore, I recently saw a monobIoo set of cylinders off a Selden chassis with the above defect, and the gudgeon pin had scored one cylinder right through into the water jacket, the water entering the cylinder and crankcase. I took the cylinders off a. 32 h.p. Continental engine latt week after three months heavy work, and found No. 2 cylinder badly scored. There were two parallel grooves -.11F in. deep down each side of the bore, caused primarily by the gudgeon pin set-screw dropping out. I recovered the set-screw from the crankcase and found its split pin in situ and well locked, but the split pin being a slack fit had turned in the screw head, and allowed the screw to come out.

"Now there are two ways of locking these setscrews on this type of engine, which I would recommend to any fellow-mechanics whe have had this trouble occur. The first, and simplest, is to drill a 3-32nd hole through the point end of the set-screw where it projects into the hollow gudgeon pin and put a long split pin in the hole, after the screw has been tightened up, opening the pin by means of a long screwdriver inserted from the other side of the hole

bored in the gudgeon pin. This method is entirely satisfactory, and was used on the 32 h.p. Hallford engine. Another method is that employed on the old twin Albion engines, and consists of a segment-shaped piece of 7.4sin. plate with a square or star-shaped hole in it: A small compression spring is threaded on the set-screw after same has been tightened up in posi_tion, then the locking plate is pressed on to the square head of the set-screw, the segment edge fitting snugly against the inner wall of the piston. The plate is forced upwards. compressing the spring slightly, and a in. split pin is inserted below the plate and opened out, thus forming a reliable locking arrangement."

For Squaring Taps.

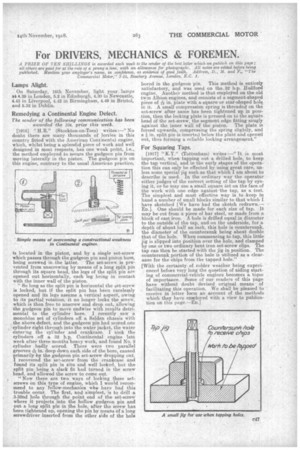

[1917] " K.Y." (Tottenham) writes :—" It. is most important, when tapping out a drilled hole, to keep the tap vertical, and in the early stages of the operation this can only be effected by using great care, unless some special jig such as that which I am about to describe is used. In the ordinary way the operator either judges of the correct setting of the tap by eyeing it, or-lie may use a small square Set on the face.of the work with one edge against the tap, as a test. The simplest and most effective way is to -keep in hand a number of small blocks similar to that which I have sketched [We have had the sketch redrawn.— En.j. One should be made for each size of tap. It may be cut from a piece of bar steel, or made from a block of cast. iron. A hole is drilled equal in diameter to the outside of the tap, and on the underside for a depth of about half an inch, this hole is countersunk, the diameter of the countersunk being about double that of the hole. When commencing to tap, this little jig is slipped into position over the laole, and clamped by one or two ordinary bent iron set-screw clips. The tap can then be started with the jig in position. The countersunk portion of the hole is utilized as a clearance for the chips from the tapped hole."

LWith the certainty of colder weather being experienced before very long the question of aiding starting of commercial-vehicle engines becomes a topic of importance. Some of our readers of this page have without doubt devised original means of facilitating this operation. We shall be pleased to receive in letter foam an account of the methods which they have employed with a view to publication on this