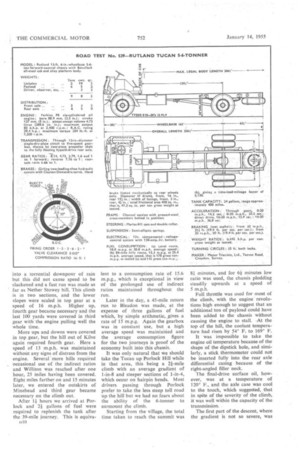

Staddard Rutland Components and Perkins P6 Engine Characterize the Tucan: Economy

Page 48

Page 49

Page 50

Page 51

If you've noticed an error in this article please click here to report it so we can fix it.

is Exceptional in Hilly. Country by John F. Moon, A.M.I.R.T.E. THE average haulier in the west of England is faced with far more rugged terrain over which ' to operate his vehicles than that

encountered in many other parts of the British Isles, and so it was with interest that I spent a day in north

Somerset with the new Rutland Tucan. Its low fuel-consumption rate when making a fast run through hilly country puts forward a strong argument in favour of using a fairly small oil engine in a 6-ton chassis, provided that the axle ratio is right.

In addition to its fuel economy and hill-climbing ability, the Tucan is a rare bird indeed. It is constructed along the usual sturdy lines asso ciated with Rutland vehicles, with a .1--in.-thick frame, five-speed gearbox and heavy-duty rear axle, yet weigh ing " under" • 3 tons in taxation condition. .

Its general -construction is almost

identical with that of Rutland 7-ton Models, but smaller tyres are fitted. In the hilly country used for the test, it was apparent that a 7-ton payload would have made little difference to its performance, and certainly the construction, of the chassis would have withstood the additional loading.

Powered lq Perkins The power unit is a Perkins P6 oil engine rated to develop 83 b.h.p. at 2,400 r.p.m., with a maximum torqueof 204 lb.-ft. at 1,500 r.p.rn_ The engine, which is fitted with an exhauster for the brake servo, is unitmounted with the David Brown 542 gearbox on four Metalastik units. The gearbox is a constant-mesh five-f speed component with .a direct-drivetop ratio and 8.14 to 1 low ratio.

The standard rear axle is a singlespeed unit with a hypoid final drive which provides a reduction ratio of 6.66 to 1. Alternatively, an Eaton 13,500 two-speed axle may be specified, in which case different gearbox ratios are used.

The chassis frame has flat and parallel longitudinals which are 71 in. deep throughout and it is braced by five pressed-steel cross-members, which are bolted in place. All framemembers are of i-in.-thick steel and minor components, such as springhanger brackets, centre bearing and fuel tank, are common to other medium-capacity vehicles in the Rutland range.

o8

.. In standard form the chassis is specified with a bonnet and cab substructure, but an all-steel cab can be supplied. This is a BonaIlack assembly, which gives the vehicle a pleasing appearance and provides good visibility, for the driver. The test vehicle also had a Bonallack 16-ft. alloy platform body with Dekaloy flooring, and the unladen weight of the complete vehicle was 2 tons 191 cwt., the cab and body weighing 9i cwt.

The Tucan was on-demonstration with .Fork Service Station, Co., Ltd., at Bleadon, near Weston-superMare, Rutland distributors for the west of England. Mr. R. E. Goodall, a director of the company, is well acquainted with operating conditions in that part of the country, having himself been a haulier, and the test was, for the most part, conducted under conditions which he knew were likely to be encountered in Somerset, Devon and Cornwall.

A payload of 6-in, concrete building blocks was provided for the test and the gross vehicle weight, with two persons in the cab, totalled 9 tons 8i cwt., the rear-axle loading being 6 tons 5 cwt, This gives a good weight-distribution factor and well within the capacity of the Michelin 8.25-28-in. (12-ply) tyres. A flat stretch of road on the A36, between East Brent and Highbridge, was chosen for the acceleration and braking trials, which I decided to carry out first because of the unsettled weather conditions. Rain beat us to it, however, and braking figures were marred by excessive wheel slip due, to the wet road surface. The deceleration rate, however, was exceptionally good and there was no appreciable delay between the depression of the brake pedal and full retardation effect on the wheels, From 20 m.p.h., the average stopping distance was 21 ft. 9 in. and from this speed the rear wheels were locked for about the last 6 ft. From 30 m.p.h., a greater degree of slippink took place and a figure of 50 ft. was obtained.

Full pedal pressure was used during these tests, but I made one stop from 20 m.p.h., using normal pressure and the Tucan came to rest in 26 ft. There was less skidding and the retardation was progressive in accordance with the pedal pressure.

The acceleration tests showed that the 6-tonner could be lively when occasion demanded and the directdrive trials from 10 m.p.h. were particularly favourable. This would be due to the low rear-axle ratio which; as shown later on in the day, allowed , top gear to be used up gradients which at first sight would seem to require the use of indirect ratios.

Consumption figures were taken during the return run to Bleadon from Edithmead, there being sixmiles of fiat road between these places. The distance was covered in 12 min. and 2.55 pints of fuel were required to top up the tank at the completion of the run. This was equivalent to a consumption rate of 18.8 m.p.g. and at no time during the run was 32 m.p.h. exceeded. This figure shows good economy when the engine is running easily and should not bematerially affected under normal traffic conditons of operation.

A supply of canned fuel was taken aboard at Edithmead and the tank was filled to overflowing prior to making a consumption run to P,orlock. I asked Mr. Goodall to drive at the speed normally used by hauliers in his district and as a result, the run was, for the most part, made at full throttle, the maximum speed of the Tucan being approximately 38 m.p.h.

The seven miles to Bridgwater were covered in 14 minutes, but in Bridgwater itself we lost time because of a I-minute traffic halt and four minutes spent in indirect ratios.

Once clear of Bridgwater we ran

into a torrential downpour of rain but this did not cause speed to be slackened and a fast run was made as far as Nether Stowey hill. This climb is in two sections, and the lower slopes were scaled in top gear at a speed of 16 m.p.h. Higher up, fourth gear became necessary -and the last 100 yards were covered in third

• gear with' the engine pulling well the whole time.

More ups and downs were covered in top gear, but the hill out of Kilve again required fourth gear. Here a speed of 13 m.p.h. was maintained without any signs of distress from the engine. Several more hills required occasional use of the indirect ratios and Williton was reached after one hour, 25 iniles having been covered. Eight miles farther on and 15 minutes later, we entered the outskirts of Minehead and third gear became necessary on the climb out.

After 11 hours we arrived at Porlock and 21 gallons of fuel were required to replenish the tank after the 39-mile journey. This is equiva D10 lent to a consumption rate of 15.6 m.p.g., which is exceptional in view of the prolonged use of indirect ratios maintained throughout the run.

Later in the day, a 45-mile return run to Bleadon was made, at the expense of three gallons of fuel which, by simple arithmetic, gives a rate of 15 m.p.g. Again the gearbox was in constant use, but a high average speed was maintained and the average consumption figure for the two journeys is proof of the economy built into this chassis.

It was only natural that we should take the Tucan up Porlock Hill while in that area, this being a 21-mite climb with an average gradient of 1-in-8 and steeper sections of 1-in-4, which occur on hairpin bends. Most drivers passing through Porlock prefer to take the less steep toll road up the hill but we had no fears about the ability of the 6-tonner to surmount the climb.

Starting from the village, the total time taken to reach the summit was

81minutes, and for 61 minutes low ratio was used, the chassis plodding steadily upwards at a speed of 5 m.p.h.

Full throttle was used for most of the climb, with the engine revolutions high enough to suggest that an additional ton of payload could have been added to the chassis without causing the engine to stall, -At the top of the hill, the coolant temperature had risen by 54° F. to 169° F.

It was impossible to take the engine oil temperature because of the shape of the dipstick hole, and similarly, a stick thermometer could not be inserted fully into the rear axle differential casing because of the right-angled filler neck.

The final-drive surface oil, however, was at a temperature of 120° F., and the axle case was cool to the touch, which suggested, that in spite of the severity of the climb, it was well within the capacity of the transmission.

The first part of the descent, where the gradient is not so severe, was made with third gear engaged and the foot brake applied to keep the road speed down to 8 m.p.h., but after I-mile, the steepness of the gradient made it expedient to engage second gear, whereafter the descent was made at 6 m.p.h., again with the foot brake partially applied.

There was a strong smell of burnt facings by the time we entered Porlock village, but an emergency stop from 20 m.p.h. produced a Tapley reading of 57% and the pedal travel had increased only by approximately 1 in. It is unlikely that such a descent would normally be made relying on the brakes alone, but it was interesting to see what slight effect it would have on the retardation power of the Rutland.

A return was made to a 1-in-4 section of the hill and a stop-start test attempted. Although the hand' brake held the vehicle, I felt that the position of the lever in relation to the seat supports and driving position could be improved. However, I understand from the manufacturers that this matter has received attention on subsequent models. This was my only criticism of an otherwise outstanding vehicle.

A successful start was made in low gear and with the good engine mountings and Layrub-jointed transmission providing a smooth take-up of torque, the chassis rapidly accelerated to the governed engine speed.