A New and Promising ALL-WEATHER HEAD

Page 47

If you've noticed an error in this article please click here to report it so we can fix it.

First-published Details of a Folding Roof for Passenger Vehicles, thhich Divides Longitudinally

WE are able to give our readers an exclusive and full description of a new. type of folding, all-weather head for coaches and buses which has been designed for quick and easy operation, inexpensive manufacture, and the elimination of folded and crumpled weatherproof materials. The design has been evolved and provisionally patented by Mr. W. L. Thurgood, a coachbuilder, of Park Road, Ware, Hertfordshire. Mr. Thin.good, who only coinineneed in the body

building industry four years ago, now has a stag of 50, and produces up to two complete coach bodies per week. He specializes strictly in building bodywork for those in the trade.

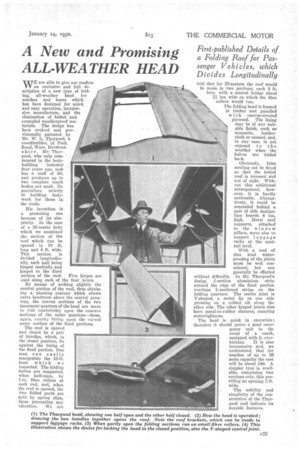

His invention is a promising one because of its simplicity. In the case of a 20-seater body which we examined the section of the roof which can be opened is 10 ft. long and 4 ft. wide. This section is divided longitudinally, each half being hinged centrally and hinged to the fixed portion of the roof. Five binges are used along each of the four joints.

By means of arching slightly the central portion of the roof, thus obtaining a pleasing contour which allows extra headroom above the central gangway, the convex sections of the two innermost quarters of the head are made to fold comfortably upon the concave sections of the outer quarters—these, again, exactly fitting upon the curved outer surface of the fixed portions.

The roof is opened and closed by a pair of handles, which, in the closed position, lie against the lining of the fixed portion. One man c an easily manipulate the 10-ft. head which we inspected. The folding halves are supported, when half-open, by 1-in, fibre rollers at each end, and, when the roof is opened, the two folded parts are held by spring clips, these preventing any vibration. We are

told that for 32-seaters the roof would be made in two portions, each 8 ft. long, with a central bridge about 21. ins, wide on which the fibre rollers would run.

The folding head is framed in timber and panelled wi th canvas-covered plywood. The lining may be of any suit able finish, such as moquette, leathercloth or enamel, and, in any ease, is not exposed to the weather when the halves are 'folded back.

Obviously, false cowling can be fitted so that the folded roof is recessed and out of sight. With out this additional arrangement, however, it is hardly noticeable. .Alterna tively, it could be concealed behind a pair of side destina tion boards 4 ins. high. Metal roof supports, attached to the window pillars, serve also to support luggage racks at the cantrail level.

With a roof of this kind water proofing of the joints must be well considered, but can generally be effected without difficulty, In Mr. Thurgood's design 3-section aluminium strip around the edge of the fixed portion overlaps L-seetioned strips on the folding quarters. The centre joint is V-shaped, a metal lip on one side pressing on a rubber rib along the other side. The other hinged joints also have metal-to-rubber closures, ensuring watertightness. The head is quick in operation ; therefore it should prove a good emergency exit in the event of a coach, equipped with it. over turning. It is also inexpensive and, we understand, that for coaches of up to 26 seats capacity the cost will he about £40. A simpler type is available, comprising two sections only, this providing an opening 3 ft. wide.

The solidity and simplicity of the construction of the Thorgood roof indicate its durable features.