MAKING BEST USE OF THE FORD.

Page 61

If you've noticed an error in this article please click here to report it so we can fix it.

Valuable Advice on Every Phase of Ford Transport which will Appeal to the Owner, Driver and Repairer.

573.—A Combined Piston-ring Squeezer and Groove Cleaner.

Many devices have appeared for cleaning the piston-ring grooves, and several specie/ tools can be obtained for this purpose. Every repair shop, however small, that undertakes engine overhauls should possess ii piston-ring squeezer. Shops that have not already got one should order Part No. 5Z290, price 9d. retell. In a very short time this useful tool can be made to clean the grooves as well as to contract the rings when refitting pistons.

Obtain a piece of -A-in. by Fin, flat steel about 2e ins. long. At one end reduce its width to I in, for a distance of e in., and then file off the end of this portion to a wedge ehape. Out a ---iii. slot abeut le ins, long in the middle a the fin. section and caseharden the wedge-shaped tip. Mark off and drill two holes in one handle of the squeezer at a distance of 1 in. and le ins, from a point where the squeezer is bent circumferentially, and tap out -ee in. C.E.I. A couple of ehert C.E.I. screws and two eerin. plain washers to screw the groove cleaner to the squeezer handle completes the tool.

Slip the squeezer over the piston and push the cleaner into the groove, until by nipping the other handle good grip can be obtained. Next tighten the two screws, then by gripping the two handles and gently turning the squeezer firound the piston—which is still on the connecting Tod and clamped in the vice— the grooves can be thoroughly cleaned in a very short time.

The wedge-sAped end will be found better for removing the carbon and the slot allows for the adjustment that will be required after sharpening. To use as a ring squeezer simply slacken the screws and push the carbon cleaner back so that the cutting edge is far enough back to clear the piston.

574.—Testing and Improving the Ignition System.

There are many points about the ignition system, defects in which may cause uneven, running or complete stoppage; to trace them proceed as fellows :—(1) Examine the coil contacts for smoothness. If pitted they should be trimmed up with a very fine file and adjusted to slightly under 1-32 in.

(2) See if there is a short in the system by turning the switch to the off position and applying one wire of a test lamp to one of the leads connected to the timer, the other wire being taken to earth—in other words, to some metallic part of the chassis. The lamp should only light when the timer arm makes contact with a segment. For this test the battery voltage may be employed, but a higher voltage, say 50, is better still. In such a case, of course, the lamp should be capable of standing this potential.

(3) With a voltmeter find the petential of the magneto. It should develop. from 14 to 18 volts. (4) If the voltage be low, this may be due to weak magnets, defective stator coils, or excessive air gap between the magnets and the coils. It is the increase in the air gap which so often causes difficult starting and results from word crankshaft bearings:

(5) See that there are no ridges in the timer. segments. If they exist remove the timer and true it in a lathe. Sometimes it will be found preferable to obtain a new timer. A weak timer spring is indicated when the engine misses at low speeds but fires regularly at medium speeds.

(6) With the switch in the off position measure the cureent passing through the magneto, when a six-volt battery is connected from the terminal to earth. Incidentally, the terminal should be connected to the positive of the battery. If the current be about 14 amps. the coils are in good order, and in all probability it is the magnets that are weak. This test should be conducted quickly, otherwise there will be an excessive drain upon the battery.

(7) If necessary, the magneto can be remagnetieed in situ. Run the car into such a position that it is facing cast or west, turn the crankshaft into such a position that when a compass is held about 2 ins, to the rear and 1e ins, to the left of the magneto terminal the north-seeking end of the needle points straight to the radiator. The south poles of the magnets will then be in correct relationship to the inducing electro magnets.

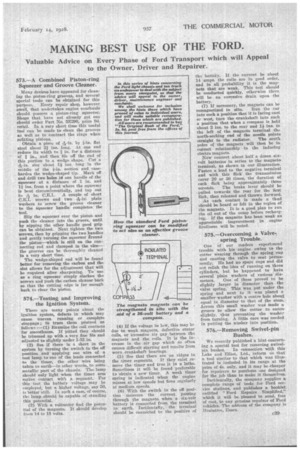

Now connect about half a dozen sixvolt batteries in series to the magneto terminal, as shown in our illustration. Fasten a lead to the negative terminal and with this flick the transmission cover 20 or 30 times, the duration of each flick being approximately three seconds. The brake lever should be pulled towards the rear for the first Hick, then released and thrown forward.

Ae each contact is made a thud should be heard or felt in the region of the magneto. It is a good plan to run the oil out of the sump before recharging. If the magneto hes been weak an appreciable improvement in engine liveliness will be noted 575.—Overcoming a Valve-, spring Trouble.

One of our readers experienced trouble with his engine owing to the cotter wearing through the spring cup and causing the valve to seat permanently. He had no spare cups and did not relish the idea of running on three cylinders, but he happened to haee several plain washers of various dia meters. Otte of these proved to be slightly larger in diameter . than the valve spring. This was put under the spring and next to it was placed a smaller washer with a centre hole about equal in diameter to that of the stem. Across this small washer was made a groove to allow the cotter to enter slightly, thus preventing the washer from turning. A little care was needed in putting the washer into position.

576.—Removing Swivel-pin Bushes.

We recently published a hint concerning a special tool for removing swivel pin bushes. In connection with this Lake and Elliot, Ltd., inform us that a tool similar to that which was illustrated is included in its range at the price of 4s. only, and it may be cheaper for repairers to purchase one designed for the job than to make it themselves.

Incidentally, the company supplies a complete range of tools for Ford service stations, and publishes a booklet entitled "Ford Repairs Simplified," which it will be pleased to send, free of cost, to any genuine repairer of Ford vehicles. The address of the company is Braintree, Essex.