London Gas Compar

Page 46

Page 47

Page 48

If you've noticed an error in this article please click here to report it so we can fix it.

s Experiences With

COAL GA: AS FUEL

EXFIAUSTIVE experiments in the use of compressed coal gas for road-transpOrt purposes are being made by the Gas Light and. Coke Co., Horseferry Road, Westminster, London, S.W.1, and the company has for some months been running with marked success a Dennis 4-tonner on this fuel.

The plant as at present used for compressing gas is of 600 cubic-ft.-per-hour capacity, and practically all the troubles and difficulties encountered have been surmounted. The company now has under consideration the question of employing gas as the source of motive power for more of its fleet of road vehicles. Such satisfactory results have apparently been obtained that it seems to us certain that the further development of the system will be extended.

The Dennis, equipped to run on gas, has already covered, so we are informed, 1,200 miles oti regular delivery of coke, etc., and on experimental work. It carries, permanently fixed, eight 1.76-cubic-ft. cylinders, containing 2,800 cubic ft. of free gas at 3,000 lb. per sq. in. pressure (200 atmospheres), which is approximately the equivalent of 12 gallons of petrol.

On one charge the 7ehicle is capable of running, on normal delivery work, somewhere in the neighbourhood of 70 miles, and we are informed that non-stop, with no load, an average consumption of about 26 cubic ft. per mile has been obtained.. .

Five Months' Unfailing Service.

During this period of experimental running and normal service, which has been in progress since November last, we understand that, except on one occasion, no failure on the road has been experienced. The exception, incidentally, was not due to exhaustion of the gas supply, nor to any fault of the gas installation.

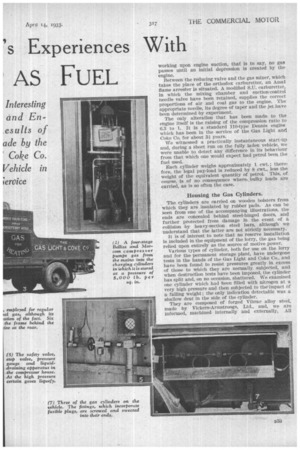

The eight cylinders are housed between the body and the chams frame, three being set transversely on each side between the driver's cab and the rear wheels and two being set longitudinally at the rear. They are all interconnected, so that only one charging valve is necessary. This is situated at the side of the vehicle, and is provided with a stop valve, a non-return valve and a screwed cap.

From the battery of cylinders the gas is conveyed to a Beings and IVIorconi pressure-reducingvalve, a pressure gauge being interposed in the circuit. The gauge is situated behind the cab in a well-protected position, but one in which it can be easily read, and is encased in a stout wire guard. The reducing valve automatically, supplies gas to the engine at approximately atmospheric pressure, and depends for its

working upon engine suction, that is to say, no gas passes until an initial depression is created by the engine. Between the reducing valve and the gas mixer, which takes the place of the orthodox carburetter, an Arnal flame arrester is situated. A modified S.U. carburetter, in which the mixing chamber and suction-control needle valve have been retained, supplies the correct proportions of air and coal gas to the engine. The appropriate needle, its degree of taper and the jet have 'been determined by experiment.

The only alteration that has been made to the engine itself is the raising of the compression ratio to (3.3 to 1. It is a standard 110-type Dennis engine which has been in the service of the Gas Light and Coke Co. for about 31 years.

We witnessed •a practically instantaneous start-up and, during a short run on the fully laden vehicle, we were unable to detect any difference in its behaviour from that which one would expect had petrol been the fuel used.

Each cylinder weighs approximately 1 cwt.; therefore, the legal pay-load is reduced by 8 cwt., less the weight of the equivalent quantity of petrol. This, of course, is of no consequence where., bulky loads are carried, as is so often the case.

Housing the Gas Cylinders.

'The cylinders are carried on wooden bolsters from which they are .insulated by rubber pads. As can be Seen from one of the -accompanying illustrations, the ends are concealed behind steel-hinged doors, and further protected from damage in the event of a collision by heavy-section steel bars, , although we understand that the latter are not strictly necessary.

It is of interest to note that no reserve installation is included in the equipment of the lorry, the gas being relied upon entirely as the source of motive power.

Various types of cylinder, both for use on the. lorry and for the permanent storage plant, have undergone tests in the hands of the Gas Light and Coke Co., and have been found to resist pressures greatly in excess of those to which they are normally, subjected, and when destruction tests have been imposed, the cylinder has split and, on no occasion, shattered. We examined one cylinder which had been filled with nitrogen' at a very high pressure and then subjected to the impact of a. falling weight ; the only indication detectable was a shallow dent in the side of the cylinder.

They are composed of forged Vibrac alloy steel, made by Vickers-Armstrongs, Ltd., and, we are informed, machined internally and externally. All fittings on the cylinders on the lorry and many of the connections exposed to permanent pressures are screwed and sweated.

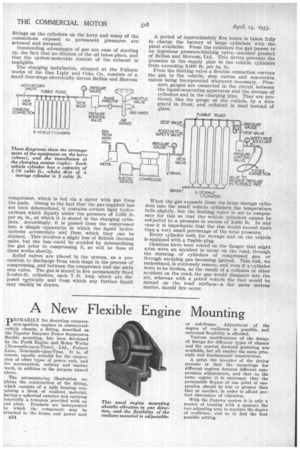

Outstanding advantages of gas are ease of starting up, the fact that no dilution of the oil takes place, and that the carbon-monoxide content of the exhaust is The charging installation, situated at the Fulham works of the Gas Light and Coke Co., consists of a small four-stage electrically driven Beliiss and Morcom

compressor, which is fed via a meter with gas from the main. Owing to the fact that the gas supplied has not been debenzolized, it contains certain light hydro-. carbons which liquefy under the pressure of 5,000 lb. per sq. in., at which it is stored in the charging cylinders. _ Accordingly, it is passed from the compressor into a simple 'apparatus in which the liquid hydrocarbons accumulate and from which they can be drained. This involves a slight loss of British thermal units, but the loss could be avoided by debenzolizing the gas prior to compressing it, as will be done at these works shortly.

Relief valves are placed in the system, as a precaution, to discharge from each stage in the process of compressing, and between the compressor and the main stop valve. The gas is stored in five permanently fixed 5-cubic-ft. cylinders, each 7 ft. long, which are disposed vIrtically and from which any further liquid may readily be drawn.

A period of approximately five hours is taken fully to charge the battery of large cylinders with the plant available. From the cylinders the gas passes to an ingenious pressure-limiting valve—another product of BeRiss and 1Vlorcom, Ltd. This device prevents the Pressure in the supply pipe to the vehicle cylinders from exceeding 3,000 lb. per sq. in.

From the limiting valve a flexible connection conveys the gas to the vehicle, stop valves and non-return valves being incorporated• wherever necessary. Pressure gauges are connected in the circuit between the liquid-separating apparatus and the storage of cylinders and in the charging pipe. They are protected, like the gauge on the vehicle, by a wire guard in front, and celluloid is used instead of glass.

When the gas expands from the large storage cylinders into the small vehicle cylinders, the temperature galls slightly, but the limiting valve is set to compensate for this so that thevehicle cylinders cannot be subjected to a pressure in excess of 3,000 lb. In any case it is improbable that the rise would exceed more than a very small percentage of the total pressure.

Every cylinder both for storage and on the vehicle is equipped with a fusible plug.

Opinions have been voiced on the danger that might arise were an accident to occur on the road, through the bursting of cylinders of compressed gas, or through escaping gas becoming ignited. This risk, we understand, is extremely remote, and even if a Jcylinder were to be broken, as the result of a collision or other accident on the road, the gas would dissipate into the air, whereas with a petrol vehicle the fuel would be spread on the road surface—a far more serious matter, should fire occur.